High-flexibility 95 ceramic and preparation method thereof

A technology with high toughness and particle size, applied in the field of ceramic materials, can solve problems affecting the performance of sintered bodies, achieve high toughness, tight combination, and promote the effect of crystal transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing high-toughness 95 porcelain, comprising the following steps: Step 1: Take magnesium hydroxide nanocrystals, place it at 400°C for 20 minutes, and then cool it to room temperature at a cooling rate of 10°C / h to prepare MgO nanoscale crystals, spare;

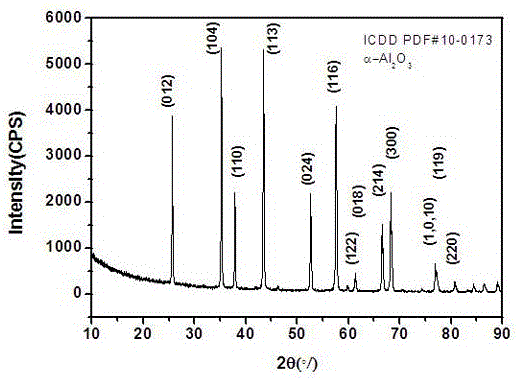

[0026] Step 2: Take the boehmite nano-whisker crystal seeds, place them in the Bayer process mother liquor, induce at a constant temperature at 95°C for 5 hours, and cool naturally to room temperature to obtain crystallization products; filter the crystallization products with suction and dry Dry and grind into powder, place the split body in deionized water for ultrasonic treatment for 1 h, and after standing still for 24 h, dry and grind at 90°C to obtain boehmite nano whiskers, place boehmite nano whiskers at 1300 ℃ for 30 minutes, and cooled to room temperature at a cooling rate of 5°C / h to prepare α-Al 2 o 3 Nanoscale crystals, spare; the α-Al 2 o 3 The XRD patterns of nanoscale crystals are ...

Embodiment 2

[0036] A method for preparing high-toughness 95 porcelain, comprising the following steps: Step 1: Take magnesium hydroxide nanocrystals, place it at 400°C for 20 minutes, and then cool it to room temperature at a cooling rate of 5°C / h to prepare MgO nanoscale crystals, spare;

[0037] Step 2: Take the boehmite nano-whisker crystal seeds, place them in the Bayer process mother liquor, induce at a constant temperature at 95°C for 5 hours, and cool naturally to room temperature to obtain crystallization products; filter the crystallization products with suction and dry Dry and grind into powder, place the split body in deionized water for ultrasonic treatment for 2 hours, after standing still for 40 hours, dry and grind at 85°C to obtain boehmite nano whiskers, place boehmite nano whiskers at 1250 ℃ for 10 minutes, and cooled to room temperature at a rate of 10℃ / h to prepare α-Al 2 o 3 nanoscale crystals, spare;

[0038] Step 3, according to MgO, α-Al 2 o 3 , Suzhou soil, s...

Embodiment 3

[0046] A preparation method of high-toughness 95 porcelain, comprising the following steps: step 1, taking magnesium hydroxide nanocrystals, and placing it at 400°C for 20 minutes, then cooling to room temperature at a cooling rate of 8°C / h to obtain MgO nanoscale crystals, spare;

[0047] Step 2: Calcining the boehmite nanocrystals at 1100°C for 22 minutes, and cooling to room temperature at a cooling rate of 8°C / h to prepare α-Al 2 o 3 nanoscale crystals, spare;

[0048] Step 3, according to MgO, α-Al 2 o 3 , Suzhou soil, silicon dioxide, and calcium carbonate=5:89.78:1.43:1.45:3.07 weight ratio, weigh the MgO prepared in step 1, and the α-Al prepared in step 2 in sequence 2 o 3 , Suzhou soil, silicon dioxide and calcium carbonate are mixed into raw meal, and the raw meal is placed in a ball mill for pulverization and ball milling until the particle size is less than 360 meshes, forming a powder for later use;

[0049] Step 4: Sieve the powder obtained by the above-men...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com