Preparation method for (para, para)-diisopropylphenyl diphenylamine product

A technology of propylphenyl diphenylamine and diphenylamine, which is applied in the field of organic compound synthesis, can solve the problems of long reaction time, poor reactivity, and impossibility, and achieve the effect of short reaction time, high reactivity, and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

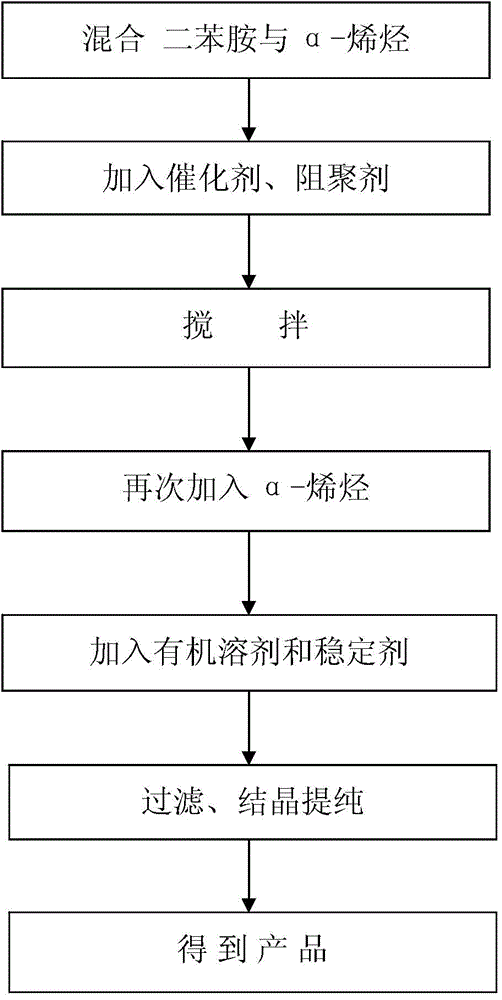

Method used

Image

Examples

Embodiment 1

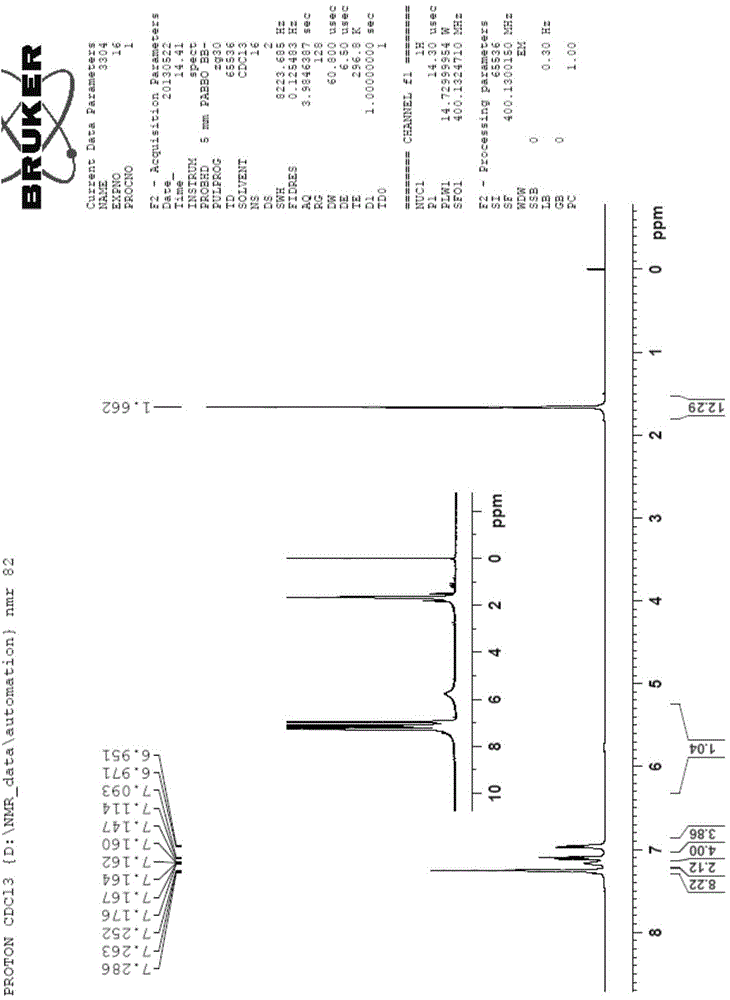

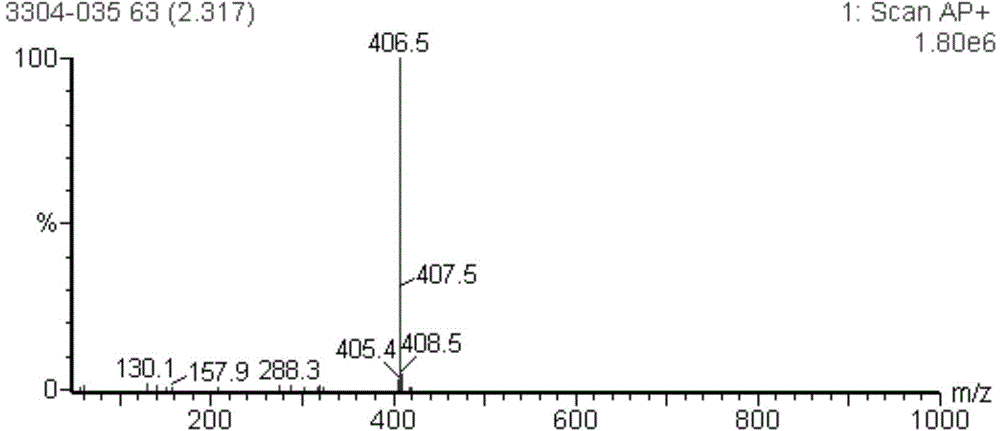

[0070] Add 50.7 g of diphenylamine and 30.8 g of α-olefin in a 500 ml glass container equipped with a stirrer, a thermometer, a heating mantle, a reflux condenser, a water separator, and a nitrogen pipeline, pass into nitrogen protection, stir with a magnetic stirrer, and After melting at 85°C, add 5g of montmorillonite-type supported catalyst, gradually increase the temperature to 145°C, add 60g of α-olefin within 5 hours, control the reflux speed and heating temperature, so that the temperature of the reactant is not lower than 120°C, and the reaction time for 8 hours. According to the TLC tracking reaction until the DPA has completely disappeared, remove the olefins, add organic co-solvent and stabilizer A to completely dissolve after cooling properly, heat filter at 45 ° C ~ 140 ° C, and distribute and purify the crystals to obtain the final product and recover olefins and catalysts , the product is a white powdery crystal. The purity is higher than 99%, and the base numb...

Embodiment 2

[0072] Add 50.7g of diphenylamine into a 500ml glass container equipped with a stirrer, thermometer, heating mantle, reflux condenser, water separator, and nitrogen pipeline, pass in nitrogen protection, stir with a magnetic stirrer, and melt at 85°C Add 5g of montmorillonite-type supported catalyst, gradually increase the temperature to 145°C, add 90.8g of α-olefin within 5 hours, control the reflux rate and heating temperature, so that the temperature of the reactant is not lower than 120°C, and the reaction time is 8 hours. According to the TLC tracking reaction until the DPA has completely disappeared, remove the olefins, add organic co-solvent and stabilizer B after proper cooling until completely dissolved, heat filter at 45°C to 140°C and distribute and purify crystals to obtain the final product and recover olefins and catalysts , the product is a white powdery crystal. The purity is higher than 99%, and the base number is 144.

[0073] The invention relates to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com