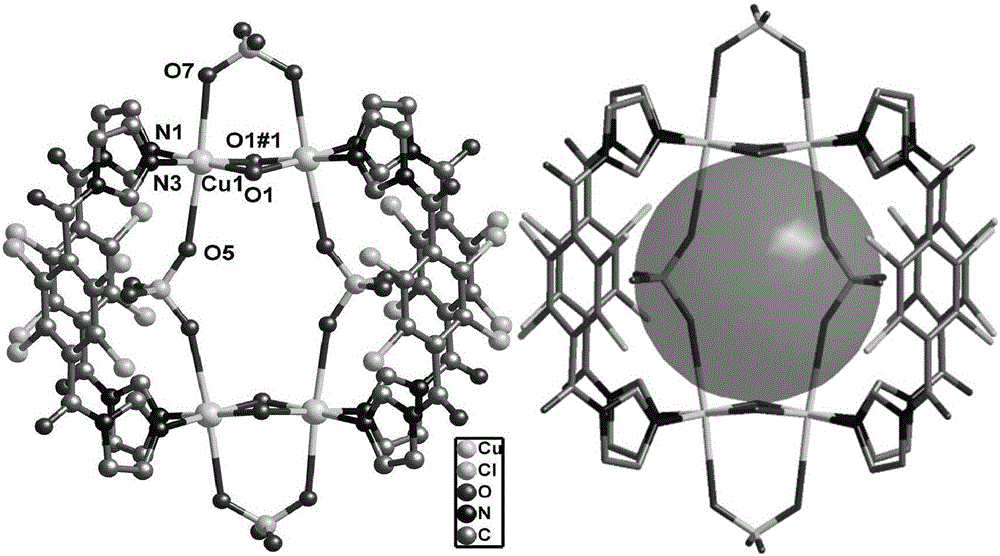

Tetranuclear copper complex, preparation method and application of tetranuclear copper complex in gas-phase amination catalysis of tetrahydrofuran

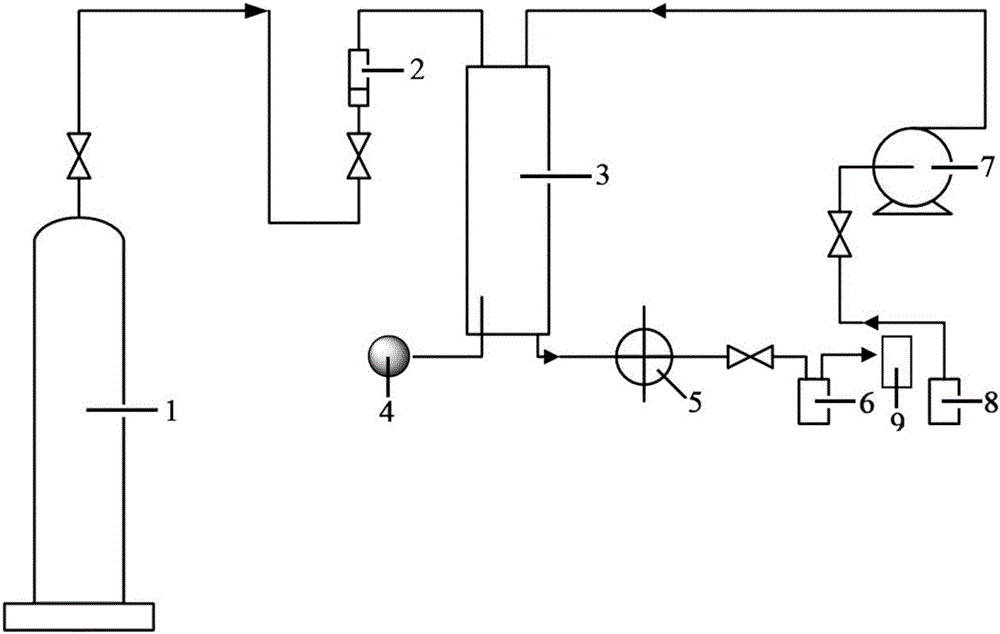

A technology of tetrahydrofuran and copper complexes, applied in organic compound/hydride/coordination complex catalysts, copper organic compounds, physical/chemical process catalysts, etc., can solve the problem of low selectivity, low cost of raw materials, and long synthesis route and other problems, to achieve the effect of simple process flow, convenient preparation and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

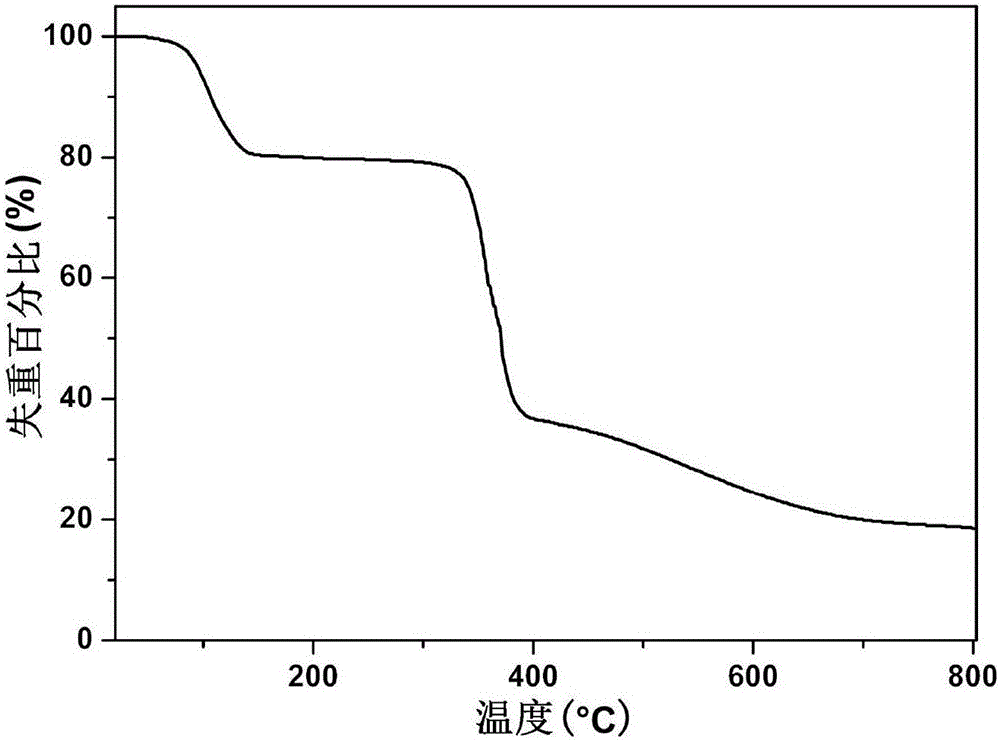

[0019] The preparation of experimental example 1 copper complex:

[0020] (1) Synthesis of Tetrachloroterephthaloyl Chloride

[0021] Weigh 10.0g (0.033mol) of tetrachloroterephthalic acid and add it into a 250mL four-necked flask, then measure 3mL (0.038mol) of refined DMF and 90mL (1.23mol) of thionyl chloride and pour them into the four-necked flask successively, After stirring, the temperature was raised to 78°C, and the temperature was kept at reflux for 4 hours to end the reaction. Distill off excess thionyl chloride under normal pressure and then under reduced pressure, rinse with a small amount of petroleum ether, wash with an appropriate amount of absolute ethanol, and dry to obtain 10.4 g of tetrachloroterephthaloyl chloride as a white solid with a yield of 92.7%, m.p. 142-143°C.

[0022] (II) Synthesis of 2,3,5,6-tetrachloro-1,4-bis(imidazole-1-carbonyl)benzene

[0023] Measure 120mL tetrahydrofuran and dissolve 10.42g (0.03) tetrachloroterephthaloyl chloride in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com