Photo-cured adhesive composition capable of adsorbing micro dust

A light-curing, adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of inability to coat, poor wettability, low surface tension, etc. Good aging resistance and the effect of increasing the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

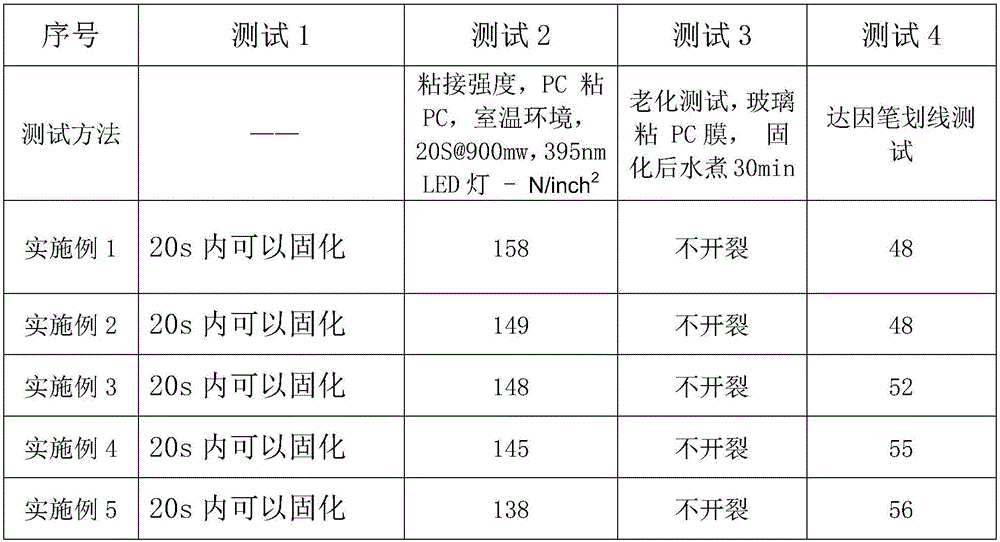

Examples

preparation example Construction

[0041] A preparation method for a photocurable adhesive composition capable of absorbing dust, comprising the following steps:

[0042] According to the ratio requirements. The adhesive composition of the present invention can be prepared by putting each raw material of the adhesive composition into the mixing tank in turn, and stirring according to a certain speed and time. The preparation process is carried out at normal temperature and pressure, and needs to be protected from light.

Embodiment 1

[0044]In the first step, weigh 45kg of urethane acrylate oligomer with a surface tension of 48dyne / cm and a viscosity of 8000mPa.s, 20kg of isodecyl acrylate and 30kg of isooctyl acrylate and put them into the mixing tank for stirring. The stirring speed is set to About 60-120rpm, stirring for about 10 minutes; the second step, weigh 3kg 1-hydroxycyclohexyl phenyl ketone and 1kg 2,4,6-trimethylbenzoyl-diphenylphosphine oxide or put it into the mixing tank Stir in the middle, the stirring speed is set at about 100-120rpm, and the stirring time is about 20 minutes; the third step, put 1kg of carbon black into the mixing tank and stir, the stirring speed is set at about 15-30rpm, the stirring time is 25 minutes, and finally the mixture Filter packs.

[0045] In this embodiment, the mass ratio of isodecyl acrylate to isooctyl acrylate is 2:3. The combined use of these two acrylates is beneficial to increase the elasticity of the adhesive composition and further enhance the adsorpt...

Embodiment 2

[0048] In the first step, 35kg of polyurethane acrylate oligomer with a surface tension of 48dyne / cm and a viscosity of 10000mPa.s, 18kg of isodecyl acrylate, 25kg of hydroxyethyl acrylate and 13kg of hydroxypropyl acrylate were weighed and put into the mixing tank for Stirring, the stirring speed is set at about 60-120rpm, stirring for about 10 minutes; the second step, 1kg2-methyl-1-(4-methylthiophenyl)-2-morpholino-1-propanone, 0.5 kg isopropylthioxanthone (2,4 isomer mixture), 1kg p-N,N-dimethylaminobenzoic acid isooctyl ester, 2.5kg o-benzoylbenzoic acid methyl ester and 4-(N,N -Dimethylamino) ethyl benzoate is weighed or dropped into the stirring tank and stirred, and the stirring speed is set at about 100-120rpm, and the stirring time is about 20 minutes; the third step, 4kg carbon black is dropped into the stirring tank and stirred, and the stirring speed is set at It is about 15-30rpm, the stirring time is 25 minutes, and finally the mixture is filtered and packaged. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com