Elliptical polarization spectrum real-time monitoring method for growth of metal film

A real-time monitoring and ellipsoidal polarization technology, which is applied in the field of real-time monitoring of vacuum coating ellipsoidal polarization spectrum, can solve the problem of not finding the public report of the real-time monitoring technology system of ellipsoidal polarization spectrum in the sample stage and test system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

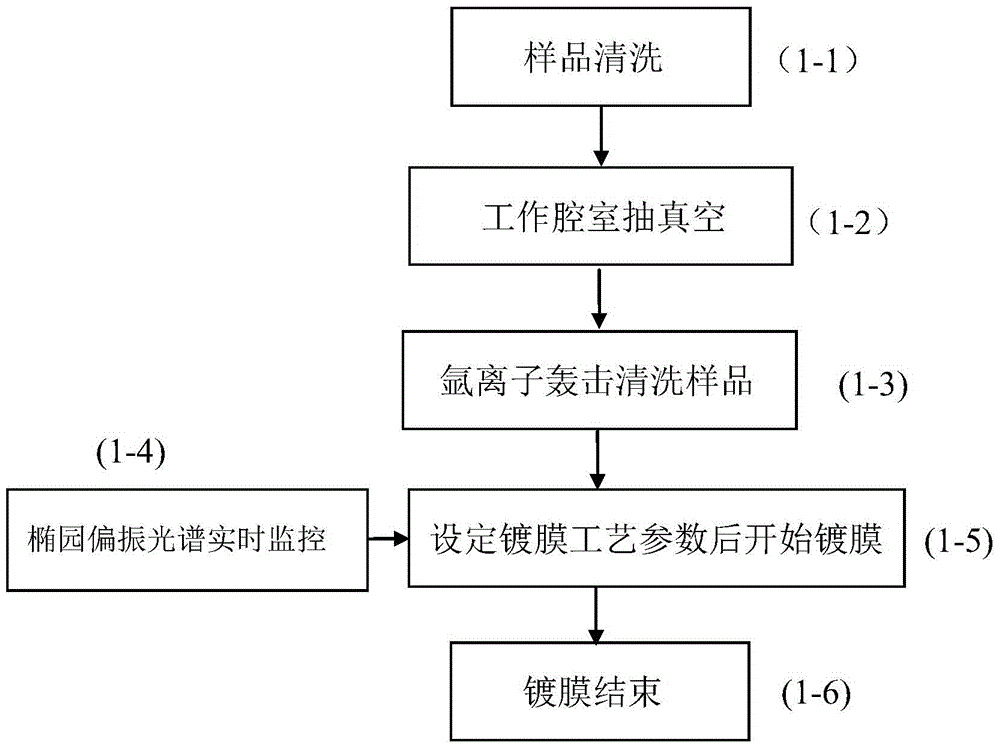

[0112] A method for real-time monitoring of metal film growth ellipsoidal polarization spectrum of the present invention comprises the following steps:

[0113] Step 1: Clean the substrate sheet by conventional cleaning method. For example: the specific cleaning plan for monocrystalline silicon wafers is to use No. 1 liquid and No. 2 liquid for cleaning silicon wafers and deionized water to clean the silicon wafers according to the prescribed process, then put them into a polytetrafluoroethylene container, and use HF to clean the silicon wafers. : Dilute solution of deionized water = 5:100 etch for about 30 seconds, then rinse with a large amount of deionized water for 3 minutes to remove the silicon dioxide layer on the single crystal silicon wafer, and then quickly blow with argon or nitrogen After drying, put it on the sample stage in the vacuum chamber.

[0114] Step 2: After the cleaned substrate is put into the predetermined position on the sample stage in the vacuum ch...

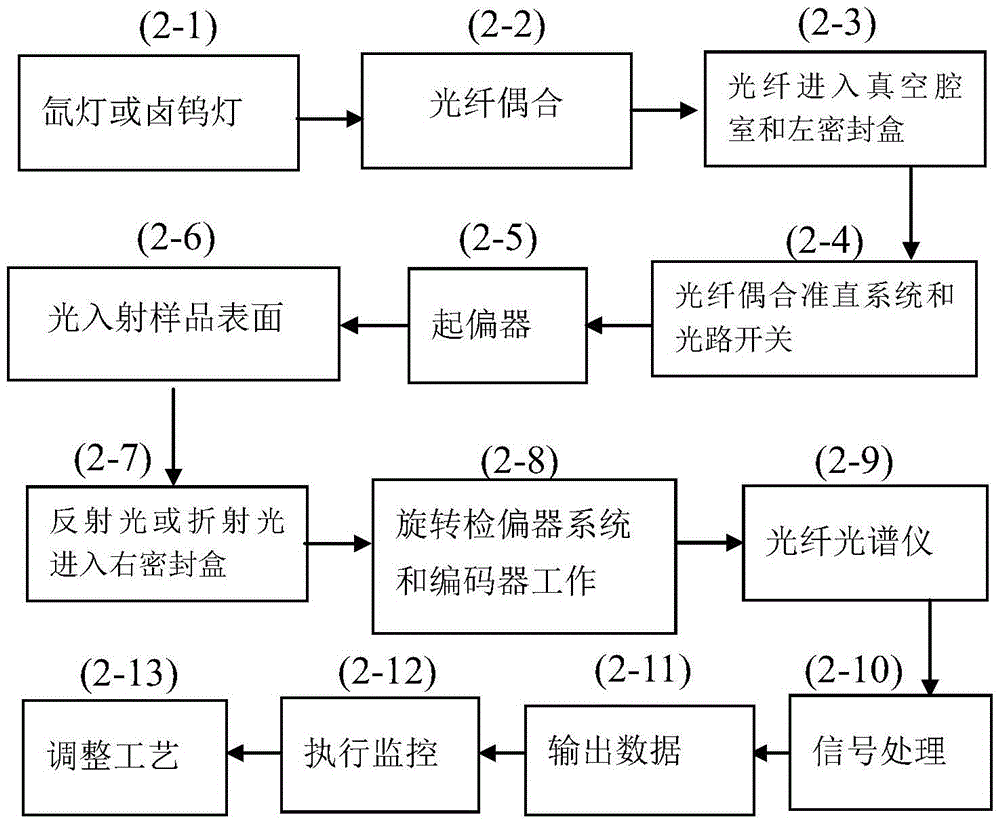

Embodiment 2

[0120] Step 1: Clean the substrate sheet by conventional cleaning method. For example: the specific cleaning plan for monocrystalline silicon wafers is to use No. 1 liquid and No. 2 liquid for cleaning silicon wafers and deionized water to clean the silicon wafers according to the prescribed process, then put them into a polytetrafluoroethylene container, and use HF to clean the silicon wafers. : Dilute solution of deionized water = 10:100 etch for about 30 seconds, then rinse with a large amount of deionized water for 3 minutes to remove the silicon dioxide layer on the single crystal silicon wafer, and then quickly blow with argon or nitrogen After drying, put it on the sample stage in the vacuum chamber.

[0121] Step 2: After the cleaned substrate is put into the predetermined position on the sample stage in the vacuum chamber, the vacuum chamber is evacuated to a certain degree of vacuum by a vacuum pumping system. For example: first use the mechanical pump to pump the v...

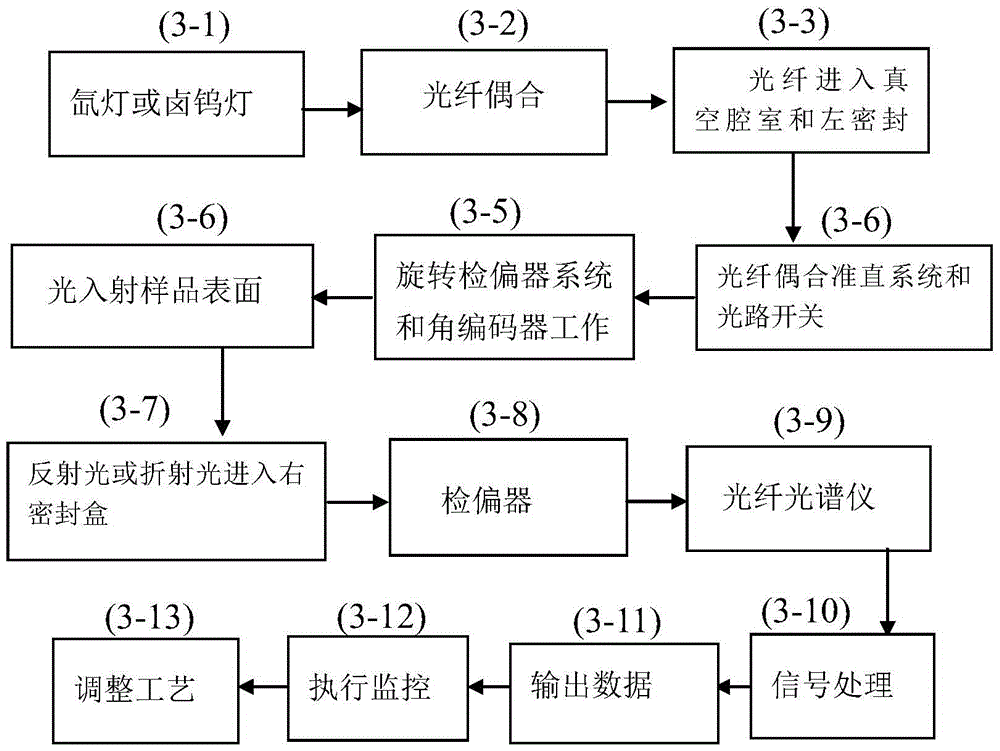

Embodiment 3

[0127] Step 1: Clean the substrate sheet by conventional cleaning method. For example: the specific cleaning plan for quartz glass is to use sulfuric acid and hydrogen peroxide to clean the quartz glass according to the prescribed process, then put it into a glass beaker and rinse it with a large amount of deionized water for 5 minutes, and then quickly dry it with argon or nitrogen Then put it on the sample stage in the vacuum chamber.

[0128] Step 2: After the cleaned substrate is put into the predetermined position on the sample stage in the vacuum chamber, the vacuum chamber is evacuated to a certain degree of vacuum by a vacuum pumping system. For example: first use the mechanical pump to pump the vacuum chamber to 2Pa, and then use the molecular pump to pump the vacuum chamber to 4×10 -4 Pa, and then use the ion pump to pump the vacuum chamber to 3×10 -6 Pa.

[0129] Step 3: Use an argon ion bombardment system to bombard the residue on the sample surface to clean the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com