Preparation method of ceramic composite modified resin coated EPS foam flame-retardant thermal-insulation material

A composite modification and resin coating technology is applied in the preparation of composite modified resin-coated EPS foam flame-retardant insulation materials, and the preparation of ceramic composite modified resin-coated EPS foam flame-retardant insulation materials can solve the problem. Residual carbon is easy to fall off, secondary unsafe, high production cost, to achieve the effects of easy availability of raw materials, good mechanical properties, and simple and easy preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

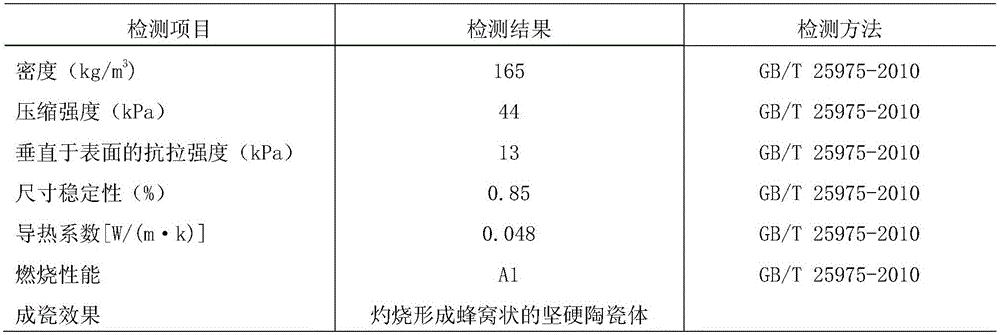

Examples

Embodiment 1

[0026] A preparation method of a ceramizable composite modified resin-coated EPS foam flame-retardant insulation material, comprising the following steps:

[0027] (1) In a 250mL three-neck flask with stirring, add 100g of silicone-modified thermosetting phenolic resin with a solid content of 70wt%, and add 25g of porcelain filler mica, 10g of wollastonite, 6g of aluminum hydroxide, and melamine under stirring. 5g of polyphosphate, 5g of low-melting-point glass powder for flux, 6g of high-melting-point glass powder, 4g of zinc borate, 0.5g of dispersant, stirred evenly, and ground with a sand mill to a fineness of ≤100 μm to obtain a composite modified phenolic resin;

[0028] (2) Add curing agent phosphoric acid 5g, petroleum sulfonic acid solution (85wt%) 5g in the composite modified phenolic resin that step (1) obtains, stir rapidly, obtain flame retardant coating agent;

[0029] (3) Add 120 g of EPS pre-expanded particles to the flame-retardant coating agent obtained in st...

Embodiment 2

[0036] A preparation method of a ceramizable composite modified resin-coated EPS foam flame-retardant insulation material, comprising the following steps:

[0037] (1) In a 250mL three-neck flask with stirring, add 100g of silicone-modified melamine resin with a solid content of 65wt%, and add 30g of porcelain filler mica, 5g of montmorillonite, 3g of magnesium hydroxide, and Aluminum 3g, ammonium polyphosphate 4g, fluxing agent low-melting point glass powder 4g, high-melting point glass powder 5g, zinc borate 6g, dispersant 0.6g, stir evenly, use sand mill to grind to fineness ≤ 80μm, to obtain compound modification Melamine resin;

[0038] (2) Add 3 g of curing agent ammonium chloride solution (50 wt %) to the composite modified melamine resin obtained in step (1), and stir rapidly to obtain a flame retardant coating agent;

[0039] (3) Add 120 g of EPS pre-expanded particles to the flame-retardant coating agent obtained in step (2), stir and mix, so that the coating agent ...

Embodiment 3

[0042]A preparation method of a ceramizable composite modified resin-coated EPS foam flame-retardant insulation material, comprising the following steps:

[0043] (1) In a 250mL three-neck flask with stirring, add 120g of thermosetting phenolic resin with a solid content of 75wt%, and add 20g of porcelain filler mica mica, 6g of wollastonite, 4g of aluminum hydroxide, and 5g of melamine polyphosphate under stirring , 3 g of low-melting glass powder, 4 g of high-melting glass powder, 2 g of zinc borate, 0.2 g of dispersant, stirring evenly, grinding with a sand mill to a fineness of ≤ 80 μm, to obtain a composite modified phenolic resin;

[0044] (2) Add curing agent phosphoric acid 8.5g, petroleum sulfonic acid solution (85wt%) 8.5g in the composite modified phenolic resin that step (1) obtains, stir rapidly, obtain flame retardant coating agent;

[0045] (3) Add 120 g of EPS pre-expanded particles to the flame-retardant coating agent obtained in step (2), stir and mix, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com