A kind of light-emitting diode and preparation method thereof

A technology of light-emitting diodes and insertion layers, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of weak luminous intensity and low hole concentration, and achieve the effects of reducing damage, increasing hole concentration, and reducing activation energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

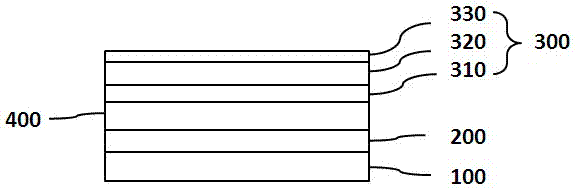

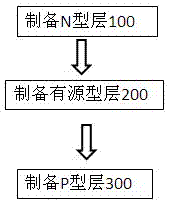

[0035] See attached figure 1 , a light-emitting diode provided by the present invention at least includes an N-type layer 100, an active layer 200, and a P-type layer 300 stacked in sequence, wherein the P-type layer 300 includes a P-type electron blocking layer 310 stacked in sequence, a high-temperature P- GaN layer 320 and P-type contact layer 330 . The N-type impurity is any one of silicon, germanium, and tin, and is used to provide electrons; the P-type impurity is any one of beryllium, magnesium, calcium, strontium, and barium, and is used to provide holes. The P-type electron blocking layer 310 is a P-type AlGaN material, and the active layer 200 is a periodic structure composed of InGaN well layers and GaN barrier layers, and the number of periods is 4-12. Since the mobility of electrons is 10 times higher than that of holes (electron mobility>1500cm 2 / vs, void 2 / vs), therefore, in order to reduce the mobility of electrons, the Al composition in the P-type electron...

Embodiment 2

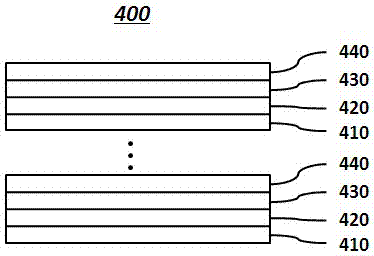

[0046] See attached Figure 5 , the difference between the present invention and Embodiment 1 is that growing a material of Al between the P-type insertion layer 400 and the P-type layer 300 x In y Ga 1-x-y The step of the transition layer 500 of N, in order to reduce the polarization effect caused by the lattice mismatch between the P-type insertion layer 400 and the P-type electron blocking layer 310, its growth temperature is between the P-type insertion layer 400 and the P-type electron blocking layer. Between the barrier layers 310, it plays a role of temperature transition, and the transition layer is Al x In y Ga 1-x-y N material layer, 0≤x<1, 0≤y<1, 0≤x+y<1. And the growth temperature of the indium source enriched layer 410, the first indium nitride layer 420, the magnesium enriched layer 430 and the second indium nitride layer 440 in the P-type insertion layer 400 is the same, and the first indium nitride layer 420 The growth time of the second indium nitride la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com