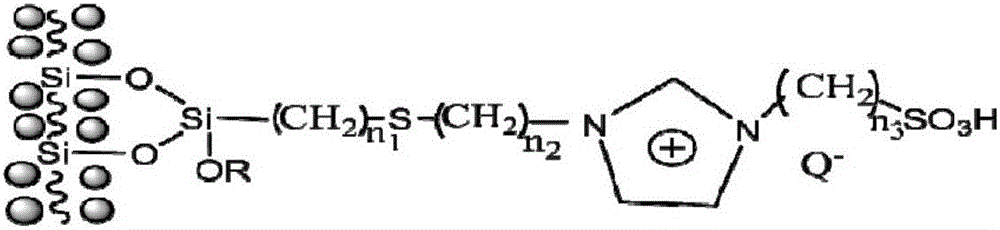

Magnetic attapulgite supported ionic liquid catalyst and preparation method thereof

A technology of ionic liquid and attapulgite, which is applied in the field of magnetic attapulgite-supported ionic liquid catalyst and its preparation, can solve the problems of reduced use efficiency, unstable performance, and inability to achieve complete recovery, and achieve enhanced binding force and excellent dispersion Sexuality, beneficial to the effect of oil catalytic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

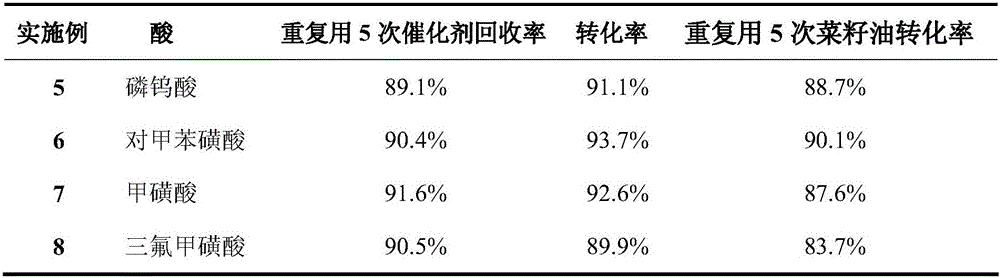

Examples

Embodiment 1

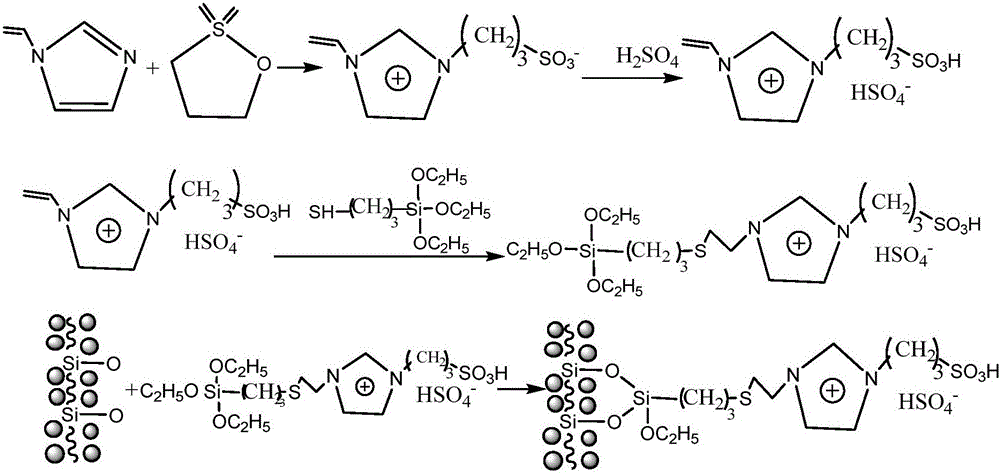

[0035] (1) Synthesis of silanized ionic liquids

[0036] Take 0.1mol of vinylimidazole and dissolve it in 60ml of toluene, slowly add 0.1mol of 1,3-propane sultone under the conditions of ice bath and vigorous stirring, after the dropwise addition, raise the temperature to 70°C, and stir it electrically for 2 hours to form a white solid , filtered the solid, washed 3 times with 60ml of ether, and dried the white solid in vacuum at 50°C for 4h to obtain 1,3-propane sultone imidazolium salt. Dissolve the white solid powder in water at 50°C, acidify by adding 0.1mol of sulfuric acid under vigorous mechanical stirring, then raise the temperature to 70°C, stir and react for 2 hours, evaporate the water in the reactant under vacuum after the reaction, and obtain light yellow oil Viscous liquid, after washing three times with 60ml ether, the final product was vacuum dried at 50°C for 24 hours, and then placed in a dry environment for later use;

[0037] Take 2.00 g of the above-prep...

Embodiment 2

[0047] Same as Example 1, the difference is:

[0048] The alkenyl imidazole compound is propenyl imidazole; the total mass of divalent iron and ferric iron ions and the mass of attapulgite are 0.40:1.

[0049] The test results of catalytic performance are as follows: the results show that the conversion rate of rapeseed oil reaches 94.4%. Compared with the catalytic effect of pure ionic liquid, the mass of ionic liquid is reduced by 40%, and the conversion rate of rapeseed oil is only reduced by 6%. After the reaction, the catalyst was recovered by filtration, and the catalyst was reused five times. The recovery rate of the catalyst reached 93.4%, the catalytic activity did not change much, and the conversion rate of rapeseed oil still reached 91.2%.

Embodiment 3

[0051] Same as Example 1, the difference is:

[0052] The sultone is 1,4-butane sultone. The total mass of ferrous iron and ferric iron ions and the mass of attapulgite are 0.08:1

[0053] The test results of catalytic performance are as follows: It was found that the conversion rate of rapeseed oil reached 93.1%. Compared with the catalytic effect of pure ionic liquid, the mass of ionic liquid was reduced by 37%, and the conversion rate of rapeseed oil was only reduced by 5%. After the reaction, the catalyst was recovered by filtration, and the catalyst was reused five times. The recovery rate of the catalyst reached 90.8%, the catalytic activity did not change much, and the conversion rate of rapeseed oil still reached 89.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com