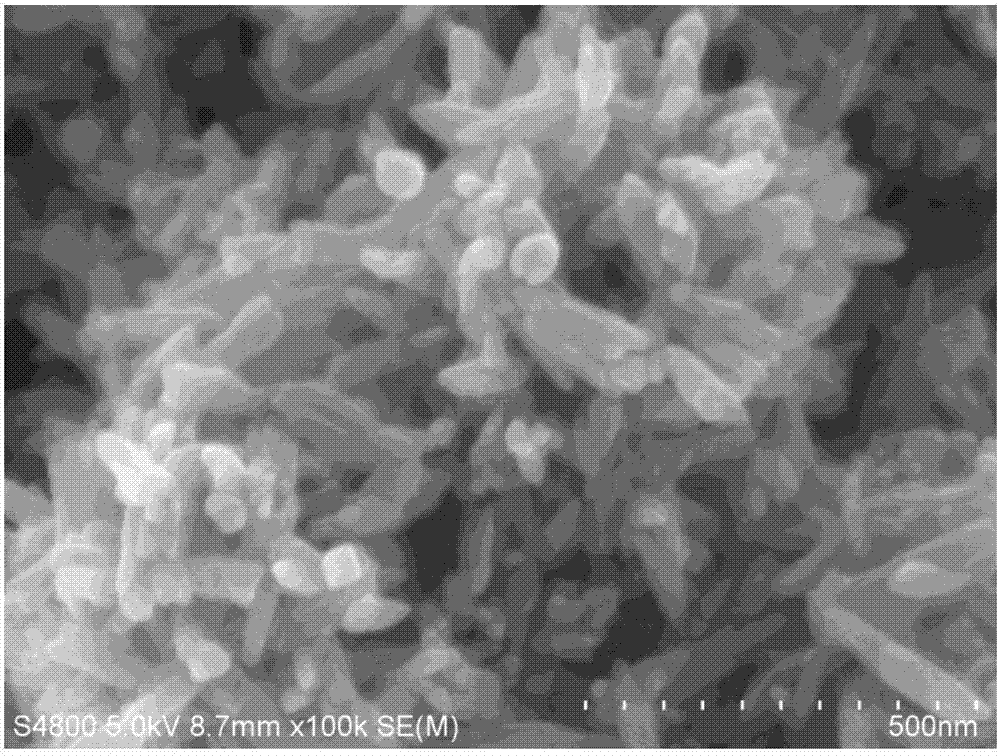

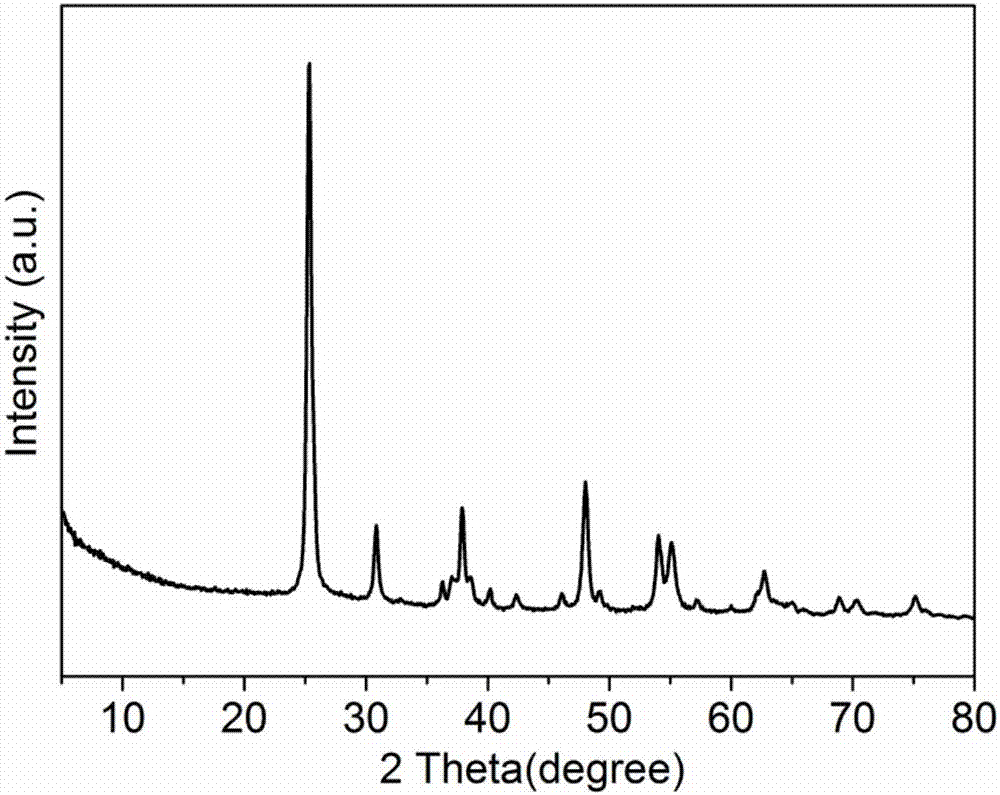

A nanorod-assembled brookite and anatase mixed phase tio 2 Micron hollow sphere and its preparation method and application

A brookite and anatase technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of lack of application value, less research on structure and performance, instability, etc., to improve the electrochemical performance. Performance, easy operation, low reaction temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A Brookite-Anatase Mixed Phase TiO with Nanorod Assembly 2 The micron hollow sphere material is prepared by the following method:

[0031] (1) Add 4.4mL of isobutyl titanate, 0.8mL of water and 1.9mL of oleylamine into 200mL of absolute ethanol, stir rapidly and uniformly for 1-2h, and obtain a white suspension, which is left to stand for 12h and then suction-filtered. White precipitate was obtained after washing and drying;

[0032] (2) Add 10mL of ethylenediamine into 40mL of deionized water, mix and stir evenly to obtain the mixed solution I;

[0033] (3) Add 0.2 g of the white precipitate obtained in step (1) into 20 mL of absolute ethanol, and stir evenly to obtain the mixed solution II;

[0034] (4) Add the mixed solution I to the mixed solution II, stir well for 2 hours, then place it in a 100mL polytetrafluoroethylene liner for hydrothermal reaction, the reaction temperature is 160°C, and the reaction time is 48 hours; then naturally cool to room temperature ...

Embodiment 2

[0037] A Brookite-Anatase Mixed Phase TiO with Nanorod Assembly 2 The micron hollow sphere material is prepared by the following method:

[0038] (1) Add 4.4mL of isobutyl titanate, 0.8mL of water and 2.0mL of oleylamine into 400mL of absolute ethanol, stir quickly and evenly for 2 hours to obtain a white suspension, leave it for 24 hours, suction filter, wash and dry A white precipitate was obtained after drying;

[0039] (2) Add 5 mL of ethylenediamine to 40 mL of deionized water, mix and stir evenly to obtain the mixed solution I;

[0040] (3) Add 0.5 g of the white precipitate obtained in step (1) into 20 mL of absolute ethanol, and stir evenly to obtain the mixed solution II;

[0041] (4) Add the mixed solution I to the mixed solution II, stir well for 2 hours, then place it in a 100mL polytetrafluoroethylene liner for hydrothermal reaction, the reaction temperature is 140°C, the reaction time is 24 hours, and then naturally cool to room temperature ; The reaction prod...

Embodiment 3

[0044] A Brookite-Anatase Mixed Phase TiO with Nanorod Assembly 2 The micron hollow sphere material is prepared by the following method:

[0045] (1) Add 4.4mL of isobutyl titanate, 0.8mL of water and 1.9mL of oleylamine into 300mL of absolute ethanol, stir quickly and uniformly for 1 hour to obtain a white suspension, leave it for 20 hours, filter it with suction, wash and dry A white precipitate was obtained after drying;

[0046] (2) Add 15mL of ethylenediamine into 40mL of deionized water, mix and stir evenly to obtain the mixed solution I;

[0047] (3) Add 0.25 g of the white precipitate obtained in step 1) into 10 mL of absolute ethanol, and stir evenly to obtain a mixed solution II;

[0048](4) Add the mixed solution I to the mixed solution II, stir well for 2 hours, then place it in a 100mL polytetrafluoroethylene liner for hydrothermal reaction, the reaction temperature is 150°C, the reaction time is 36 hours, and then naturally cool to room temperature . The reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com