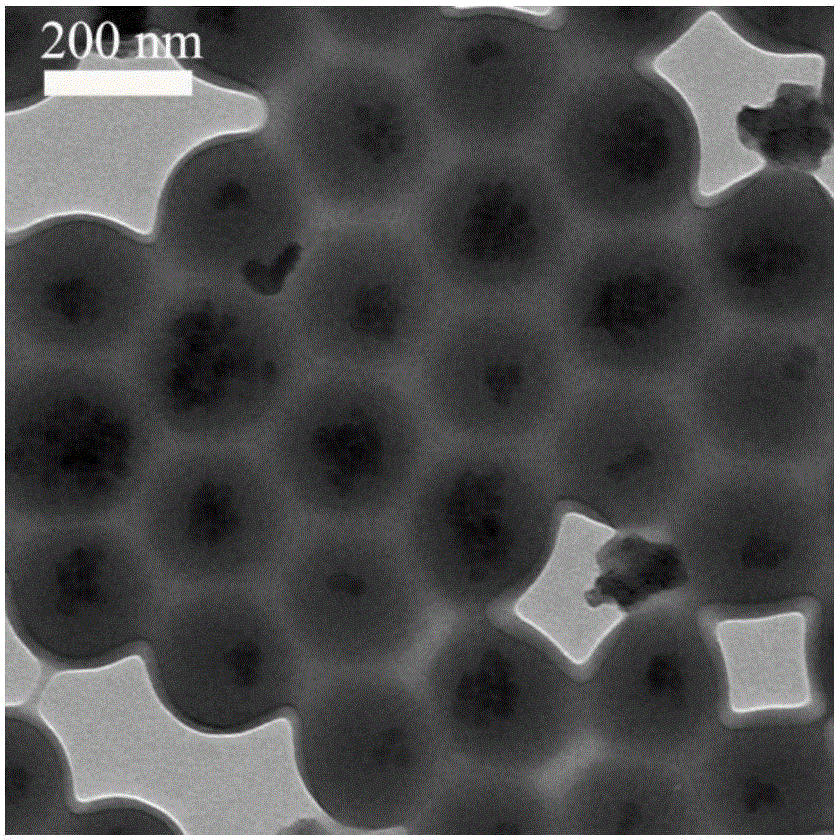

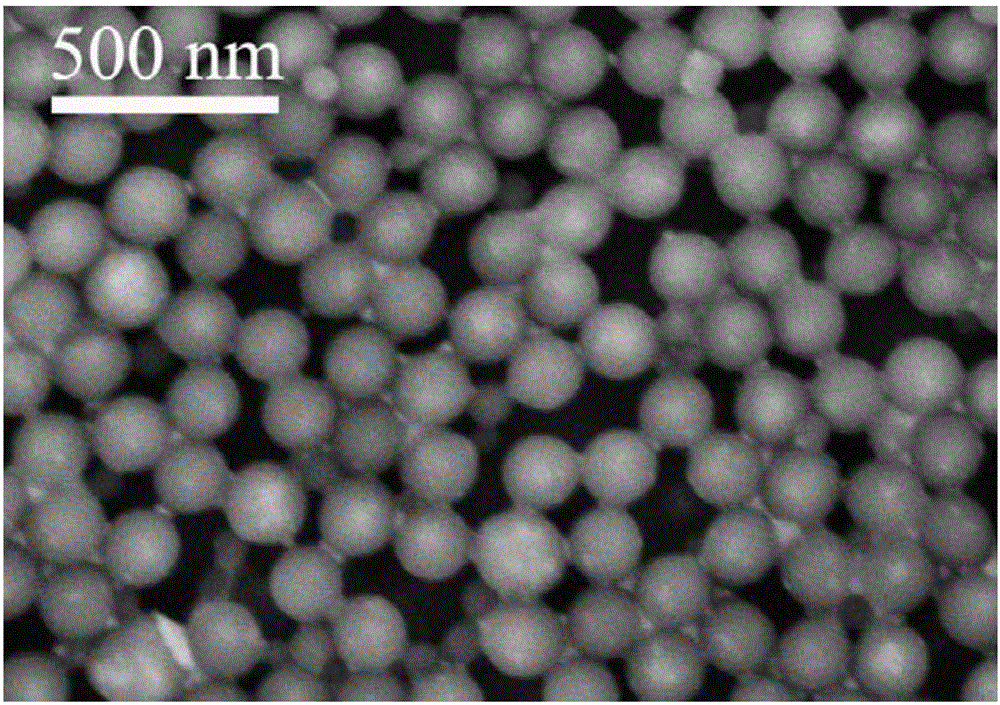

Preparation method of monodisperse polymer/SiO2 nano composite particles

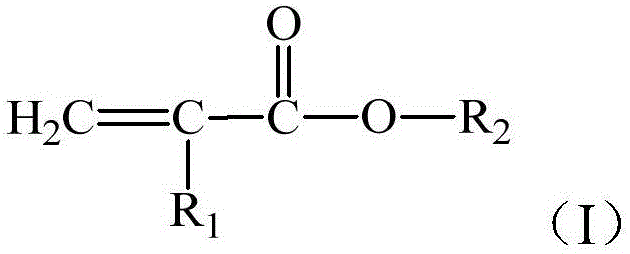

A nano-composite particle and polymer technology, applied in the field of monodisperse polymer/SiO2 nano-composite particles, can solve the problems of reducing the composite efficiency of inorganic particles and polymers and increasing the solubility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Tween-20 was selected as the non-ionic emulsifier, and 1.25 g was weighed and dissolved in 125 g of water to obtain an aqueous solution of Tween-20.

[0038] 8gSiO 2 Nanoparticles (15nm, coupling density 3.5μmol·(m 2 SiO 2 ) -1 ) pre-dispersed in 32g of methyl methacrylate, plus 13.6g of styrene and 2.2g of n-hexadecane to obtain SiO 2 Monomer dispersion of nanoparticles.

[0039] SiO 2 The monomer dispersion of nanoparticles is added to the aqueous solution of Tween-20, and the coarse emulsion is obtained after pre-emulsification. The container containing the coarse emulsion is placed in an ice-water bath, and a stable single body lotion. Take by weighing 0.013g dodecyl dimethyl hydroxypropyl sulfobetaine again, add in the monomer miniemulsion, stir 15min, then add 0.7g water-soluble initiator potassium persulfate, nitrogen deoxygenation, temperature rising Reaction at 75°C for 3h under nitrogen protection to obtain monodisperse polymer / SiO 2 nanocomposite part...

Embodiment 2

[0042] Use OP-10 as the non-ionic emulsifier, weigh 10 g, and dissolve it in 125 g of water to obtain an aqueous solution of OP-10.

[0043] 1.5gSiO 2 Nanoparticles (30nm, coupling density 2.5μmol·(m 2 SiO 2 ) -1 ) pre-dispersed in 13.5g methyl methacrylate, then add 5g 3-trimethoxysilyl methacrylate and 1.48g n-hexadecane to get SiO 2 Monomer dispersion of nanoparticles.

[0044] SiO 2 The monomer dispersion of nanoparticles is added to the aqueous solution of OP-10, and the coarse emulsion is obtained after pre-emulsification. The container containing the coarse emulsion is placed in an ice-water bath, and the ultrasonic power of 500W is ultrasonicated for 5 minutes to obtain a stable monomer. fine emulsion. Then weigh 1.13g of cetyltrimethylammonium bromide, add it to the monomer miniemulsion, stir for 30min, then add 0.19g of water-soluble initiator 2,2'-azobisbutylamidine dihydrochloride , Nitrogen to remove oxygen, the temperature rises to 65 ° C, and reacts for 5...

Embodiment 3

[0047] The non-ionic emulsifier is MOA-9, weigh 0.5g, dissolve it in 125g water, and obtain the aqueous solution of MOA-9.

[0048]0.2gSiO 2 Nanoparticles (50nm, coupling density 2.0μmol·(m 2 SiO 2 ) -1 ) pre-dispersed in 7.3g of methyl methacrylate, plus 2.5g of butyl acrylate and 0.3g of n-hexadecane to obtain SiO 2 Monomer dispersion of nanoparticles.

[0049] SiO 2 The monomer dispersion of nanoparticles is added to the aqueous solution of MOA-9, and the coarse emulsion is obtained after pre-emulsification. The container containing the coarse emulsion is placed in an ice-water bath, and the ultrasonic power of 60W is ultrasonicated for 45 minutes to obtain a stable monomer. fine emulsion. Then weigh 0.18g of sodium lauryl sulfate, add it to the monomer miniemulsion, stir for 30 minutes, add 0.03g of sodium bisulfite to the above monomer miniemulsion, pass nitrogen to remove oxygen, and the temperature rises to 40°C , then add 0.05g ammonium persulfate, and react for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com