Preparation method of anti-fog and anti-ultraviolet polyester film

A polyester film, anti-ultraviolet technology, applied in the field of polyester film, can solve the problems of agglomeration, small size, unable to achieve efficient synergy of organic and inorganic modified components, etc., to achieve good compatibility and ensure the effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preparation method of the anti-fog and anti-ultraviolet polyester film of the present invention comprises sequentially the synthesis of a hydrophilic anti-ultraviolet prepolymer, the preparation of a hydrophilic and anti-ultraviolet modified polyester, and the processing to prepare an anti-fog and anti-ultraviolet polyester film. Specifically follow the steps below:

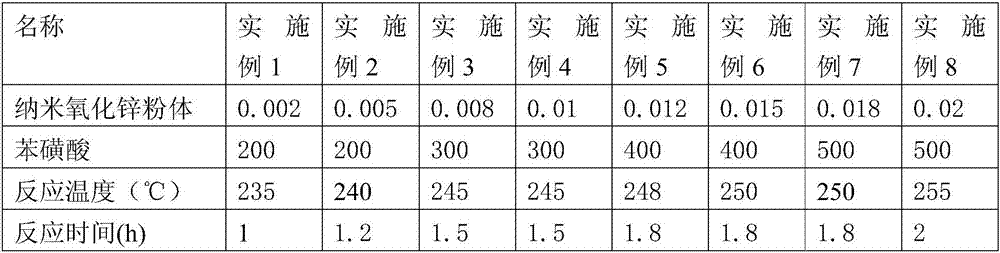

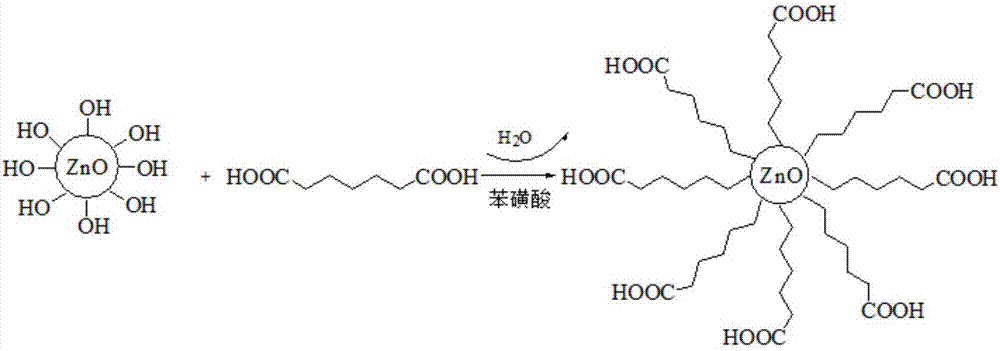

[0029] The first step: Synthesis of hydrophilic anti-ultraviolet HOOC-(NHCO)n-COO-ZnO prepolymer.

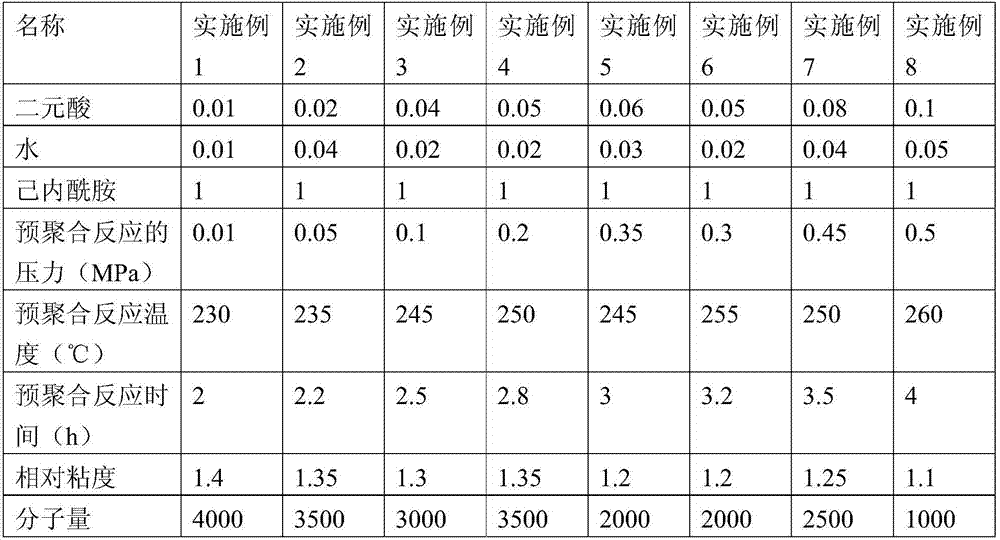

[0030]Dibasic acid, water, and caprolactam are fully mixed according to the molar ratio of 0.01-0.1:0.01-0.05:1 to carry out prepolymerization reaction. The dibasic acid of the present invention is the end-capping agent of polyamide, and the dibasic acid adopts oxalic acid, One of succinic acid, adipic acid or glutaric acid or a mixture of any two or more, the dibasic acid of the present invention is an organic dibasic acid, and oxalic acid, succinic acid, adipic acid or glutaric acid Any two or more ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com