A kind of skin dressing and preparation method thereof

A skin-to-skin contact technology, applied in medical science, absorbent pads, bandages, etc., can solve problems such as the speed of drug release not meeting the requirements, and achieve the effects of accelerated release, directional induction repair, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of skin dressing includes doping method and suction filtration method, wherein the doping method includes the following steps:

[0050] (1) Soak a bacterial cellulose film with a thickness of 3 mm to 14 mm in a solution or suspension of a conductive material, so that the conductive material penetrates into the surface of the bacterial cellulose film at 1 mm to 3 mm, and the surface is conductive The content of the material is 5mg / cm 2 ~50mg / cm 2 ;

[0051] (2) Cut the bacterial cellulose film in a direction parallel to the surface, and control the thickness of the cut to obtain a composite hydrogel film of 2mm-7mm;

[0052] (3) Soak the composite hydrogel film in a drug solution with a concentration of 2μg / ml-20μg / ml for 12h~48h to make the surface of the composite hydrogel film adsorb 2μg / cm 2 ~20μg / cm 2 To obtain the skin dressing; the drug is one or more of blood coagulation drugs, anti-allergic drugs, analgesics, and cell growth factors.

[0053] Wher...

Embodiment 1

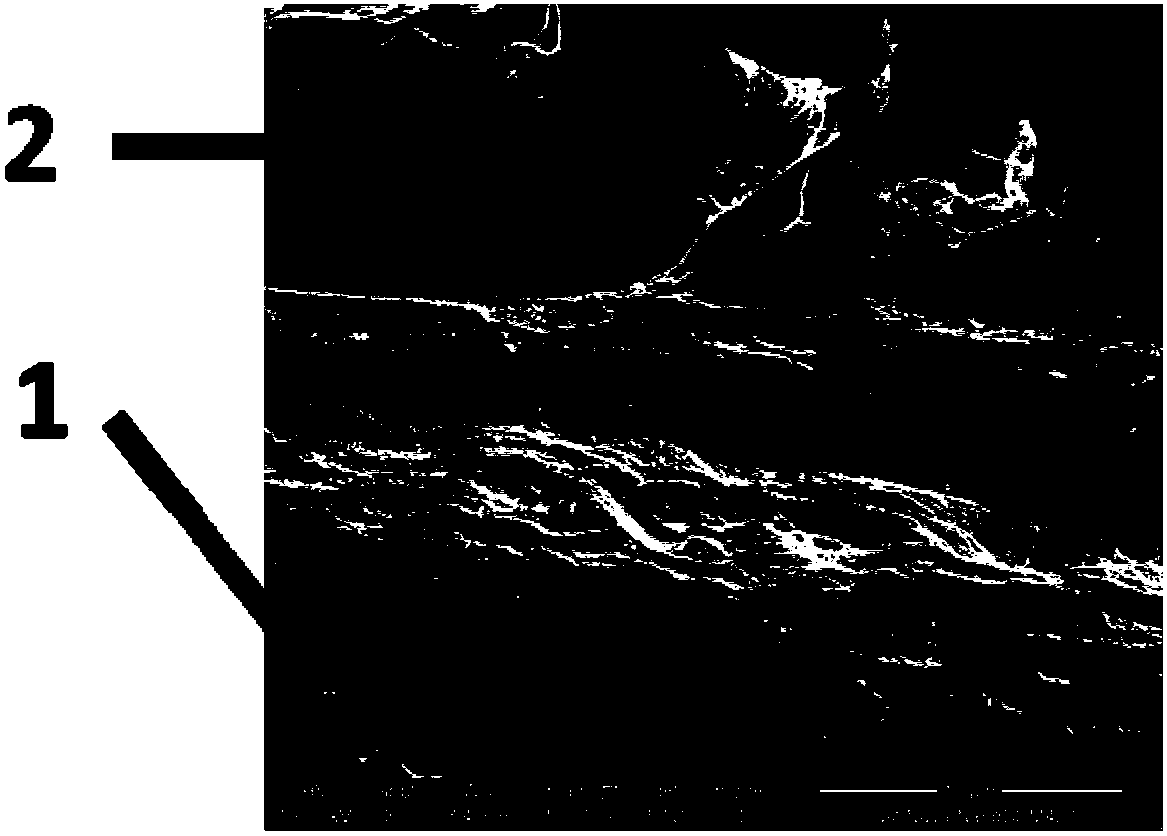

[0065] Use Acetobacter gluconobacter ATCC53582, inoculate it in S-H medium (medium composition: 1L of water containing 20 grams of glucose, 5 grams of yeast powder, 5 grams of peptone, 1.5 grams of citric acid, 2.7 grams of disodium hydrogen phosphate). After standing and culturing at 26°C for 15 days, a bacterial cellulose hydrogel hydrogel with a thickness of about 10mm-12mm is obtained. Soak the bacterial cellulose hydrogel in distilled water for two days, then boil it in 1wt% sodium hydroxide solution for 30 minutes, take it out and wash it with distilled water until it is neutral to obtain a pure bacterial cellulose hydrogel at 4°C Save it for later use.

[0066] (1) The bacterial cellulose hydrogel is soaked in a 20% ammonium persulfate solution and allowed to stand for 24 hours. Take it out, rinse the surface with distilled water three times, then soak the bacterial cellulose hydrogel in a 1:10 volume solution of pyrrole monomer and ethanol, and let it stand for 0.5 hours...

Embodiment 2

[0071] Example 1 was repeated with the same steps as described, except that the aniline monomer was substituted for the pyrrole monomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com