A method for strengthening anaerobic dry fermentation of dewatered sludge to produce methane

A technology for dewatering sludge and dry fermentation, applied in dehydration/drying/concentrated sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Inhibition of the biological functions of the oxygen-methanogenic flora, etc., to reduce the formation and emission of odors, increase the content of soluble nucleic acids, and avoid system crashes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Fully mix the dewatered sludge with a water content of 80% and CaO whose weight is 1% of the weight of the dewatered sludge, put it into a steam explosion kettle, and close the valve. Raise the temperature to 180°C, raise the pressure to 1Mpa, and maintain it for 15 minutes. Open the discharge valve, collect the material after instantaneous pressure release, and let it stand for 10 minutes to separate the sediment to obtain pretreated sludge.

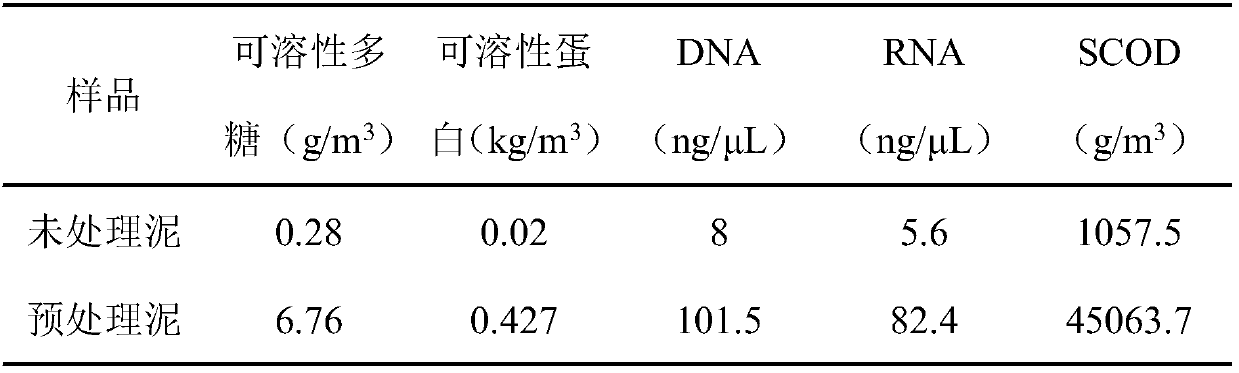

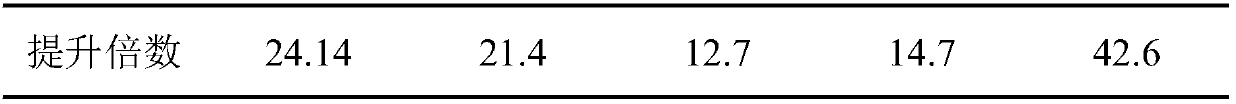

[0043] After the steam explosion pretreatment method, the pretreated sludge and the untreated sludge have enhanced solubility and increased hydrolysis degree. The specific results are shown in Table 1:

[0044] Table 1

[0045]

[0046]

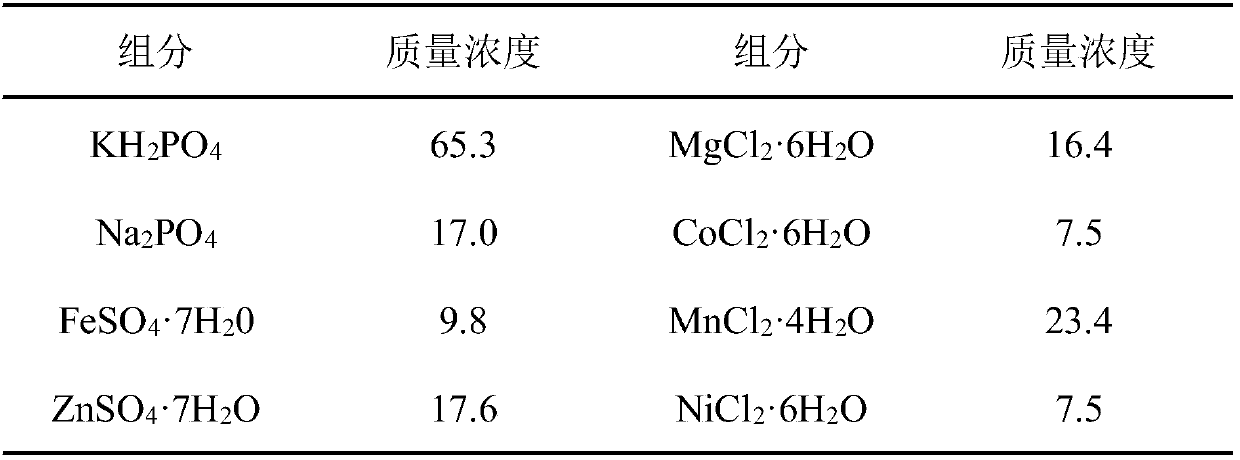

[0047] Feed the material proportionally to CO 2 (200L / kgTS), stir well until pH=8.5. Introduce 1% untreated sludge, place it at 30°C for 24 hours under facultative aerobic conditions, and feed 10L / kgTS air at the same time to acidify it.

[0048] Take out the material after acidificati...

Embodiment 2

[0055] Set up an experimental group (hereinafter referred to as CaO steam explosion): fully mix dewatered sludge with a moisture content of 60% and CaO with a weight of 5% of the weight of the dewatered sludge, put it into a steam explosion kettle, and close the valve. Raise the temperature to 200°C, increase the pressure to 1Mpa, and maintain it for 30 minutes. Open the discharge valve, collect the material after instantaneous pressure release, and let it stand for 30 minutes to separate the sediment to obtain pretreated sludge.

[0056] References (C.Park, C.Lee, S.Kim, Y.Chen, H.A.Chase, Upgrading of anaerobic digestion by incorporating two different hydrolysis processes, J.Biosci.Bioeng.100(2)(2005)164–167.) , set up a control group (hereinafter referred to as NaOH high temperature): the same dewatered sludge was mixed with NaOH, maintained at 121 ° C for 30 minutes, and collected after the temperature cooled to obtain NaOH high temperature pretreated sludge.

[0057] Aft...

Embodiment 3

[0075] Set up an experimental group (hereinafter referred to as CaO steam explosion): fully mix dewatered sludge with a moisture content of 70% and CaO with a weight of 3% of the weight of the dewatered sludge, put it into a steam explosion kettle, and close the valve. Raise the temperature to 190°C, increase the pressure to 1.5Mpa, and maintain it for 30 minutes. After the reaction is finished, open the discharge valve, collect the material after instantaneous pressure release, and let it stand for 20 minutes to separate the sediment to obtain pretreated sludge.

[0076] With reference to the method of Chinese patent CN103172237A, a control group (hereinafter referred to as steam explosion) is set up: the same dewatered sludge is directly subjected to steam explosion under the same temperature, pressure and reaction time conditions as the experimental group to obtain steam explosion pretreated sludge.

[0077] The solubility of the pretreated sludge was enhanced, and the degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com