Preparation method and application of reactive type halogen-free flame-retardant polyether glycol

A flame-retardant polyether, reactive technology, applied in the field of organic synthesis, can solve the problems of containing a large amount of halogen, low functionality, high price, etc., and achieve the effects of good stability, good compatibility and moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

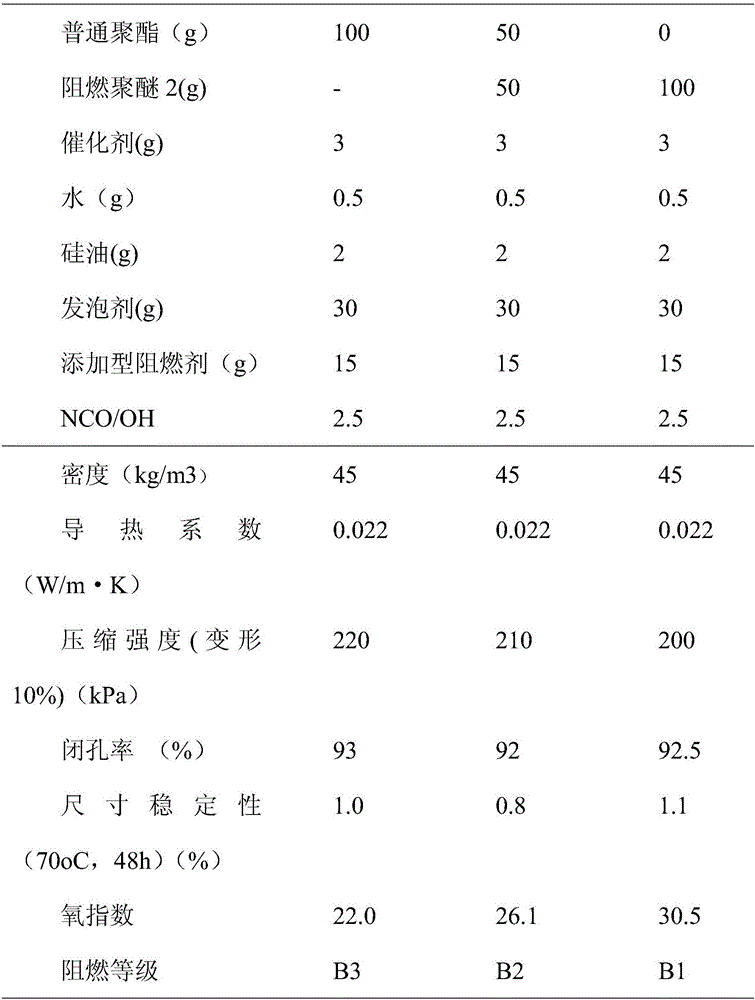

Examples

Embodiment 1

[0022] Weigh 271 g of tetrakis hydroxymethyl phosphorus sulfate aqueous solution (containing 203 g of tetrakis hydroxymethyl phosphorus sulfate), add 56 g of potassium hydroxide into a 1L three-necked flask equipped with mechanical stirring, thermometer and condenser tube, cool to 0°C and maintain this temperature Stir for 5 hours.

[0023] The product obtained in the first step reaction was distilled off under reduced pressure to remove the solvent water, and then 62g of ethanol was added at room temperature to dissolve the product, and then sent to a centrifuge to remove solid by-products, and then heated to 80°C and stirred for 3 hours. The ethanol was distilled off under reduced pressure to obtain the product trihydroxymethylphosphine oxide, and the reaction yield was 96%.

[0024] Weigh 124g of the product obtained in the third step reaction, add 0.62g of triethylamine into a pressure reactor, and start feeding propylene oxide when the temperature rises to about 80°C. Dur...

Embodiment 2

[0026] Weigh 253g of tetrakishydroxymethylphosphorus chloride aqueous solution (containing 190g of tetrakishydroxymethylphosphorus chloride), add 148g of calcium hydroxide into a 1L three-necked flask equipped with mechanical stirring, thermometer and condenser, and cool to -10°C Stirring was maintained at this temperature for 3 hours.

[0027] The product obtained in the first step reaction was distilled off under reduced pressure to remove the solvent water, and then 41g of methanol was added at room temperature to dissolve the product, and then sent to a centrifuge to remove solid by-products, and then heated to 70°C and stirred for 2 hours. After the reaction was completed, Methanol was distilled off under reduced pressure to obtain the product trihydroxymethylphosphine oxide, and the reaction yield was 95%.

[0028] Weigh 130g of the product obtained in the third step reaction, add 1g of potassium hydroxide into a pressure reactor, and start feeding propylene oxide when t...

Embodiment 3

[0030] Weigh 314 g of tetrakis hydroxymethyl phosphorus bromide aqueous solution (containing 235 g of tetrakis hydroxymethyl phosphorus bromide), add 200 g of sodium hydroxide into a 1L three-necked flask equipped with mechanical stirring, thermometer and condenser tube, and cool to -20°C Stirring was maintained at this temperature for 8 hours.

[0031] The product obtained in the first step reaction was distilled off under reduced pressure to remove the solvent water, and then 31g of acetone was added at room temperature to dissolve the product, and then sent to a centrifuge to remove solid by-products, and then heated to 50°C and stirred for 5 hours. The acetone was distilled off under reduced pressure to obtain the product trihydroxymethylphosphine oxide, and the reaction yield was 95%.

[0032]Weigh 132g of the product obtained in the third step reaction, add 0.8g of sodium hydroxide into a pressure reactor, and start feeding ethylene oxide when the temperature rises to ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com