PVD coating on surface of airspeed head and preparing method of PVD coating

A pitot tube and coating technology, which is applied in the direction of vacuum evaporation coating, coating, sputtering coating, etc., can solve the problem of incomplete coating on the surface of pitot tube, loss of performance of pitot tube, and failure to meet the requirements of appearance And other problems, to avoid chemical poisoning, avoid scrapping, uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

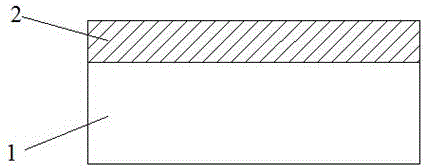

[0029] A PVD coating on the surface of pitot tube, such as figure 1 As shown, a Cr metal layer is directly plated on the surface of the pitot substrate. The thickness of the Cr metal coating is 5 μm.

[0030] The PVD coating equipment used in the present invention is a magnetron sputtering equipment, and the magnetron sputtering equipment is composed of a vacuum chamber, a magnetic pole, a single metal target, a sample holder, an air inlet and a software control system. The concept of unbalanced magnetron sputtering is used for sputtering, so that the deposition rate of the coating is high and the temperature rise of the substrate is low.

[0031] A method for preparing a PVD coating on the surface of a pitot tube, the steps of which are as follows:

[0032] 1) Finely grind and polish the corroded or scratched pitot tube to make the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com