Method for preparing butterfly-scale-structure material through micro-nano laminated film slitting

A technology of structural materials and micro-nano lamination, applied in textiles and papermaking, fiber processing, filament/thread forming, etc., can solve the problems of inapplicability, no further corresponding in-depth research and modification, etc., and achieve low cost , increase the biaxial stretching process, the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

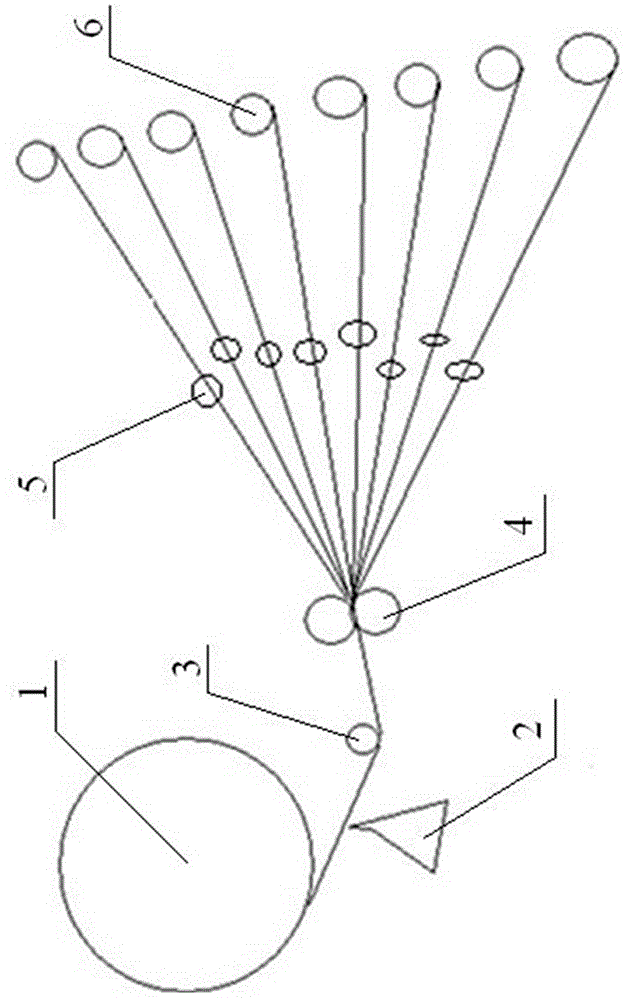

[0021] Such as figure 1 As shown, the method for preparing the butterfly scale structure material by cutting the micro-nano laminated film in this example includes the following steps: (1) wrapping the micro-nano laminated film 1 with a diameter of 60 cm, a thickness of 100 μm, and a width of 100 mm During the unwinding process, a layer of titanium oxide nanotube aqueous emulsion (containing 1% solid content) with a thickness of 5um is coated on the surface of the micro-nano laminated film by the slit coating head 2, and then, it is layered by the guide roller 3 Superposed extrusion film forming is processed into a composite film with a thickness of 100um, the composite film contains 100 layers, each of which is less than 1um in thickness, and a single-layer film with a thickness of 400nm is obtained by biaxial drawing; (2) The film slitting machine 4 for the single-layer film prepared in step (1) adopts the slitting form of a mechanical rotary circular blade module at a speed...

Embodiment 2

[0023] In this example, the method for preparing the butterfly scale structure material by cutting the micro-nano laminated film includes the following steps: (1) stacking the micro-nano laminated film with a diameter of 60 cm, a thickness of 80 μm, and a width of 100 mm in layers Extruded into a film and processed into a composite film with a thickness of 80um, the composite film contains 90 layers, each of which has a thickness of less than 1um, and a single-layer film with a thickness of 300nm is obtained by biaxial drawing; (2) the step (1) The film slitting machine for the prepared single-layer film adopts the slitting form of a straight blade module at a speed of 100m / s to cut the micro-nano laminated film into 100 continuous butterfly scales with a width of 1.0mm Structural material flat wire; (3) Each flat wire of continuous butterfly scale structural material is made into a group, heated by a heating device at 150 degrees, and the continuous butterfly scale structural ...

Embodiment 3

[0025] In this example, the method for preparing the butterfly scale structure material by cutting the micro-nano laminated film includes the following steps: (1) stacking the micro-nano laminated film with a diameter of 60 cm, a thickness of 50 μm, and a width of 100 mm in layers Extruded into a film and processed into a composite film with a thickness of 50um. The composite film contains 60 layers, each of which has a thickness of less than 1um. A single-layer film with a thickness of 100nm is obtained by biaxial drawing; (2) the step (1) The film slitting machine for the prepared single-layer film adopts the slitting form of the straight blade module at a speed of 200m / s, and cuts the micro-nano laminated film into 1176 continuous butterfly scales with a width of 0.085mmmm Structural material flat wire; (3) Each flat wire of continuous butterfly scale structural material is made into a group, heated by a heating device at 210 degrees, and the continuous butterfly scale struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com