Metal oxide semiconductor diode with accumulation layer

A technology of oxide semiconductor and accumulation layer, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of low forward voltage drop and high forward voltage drop, and achieve low forward voltage drop and low conduction The effect of voltage and high withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

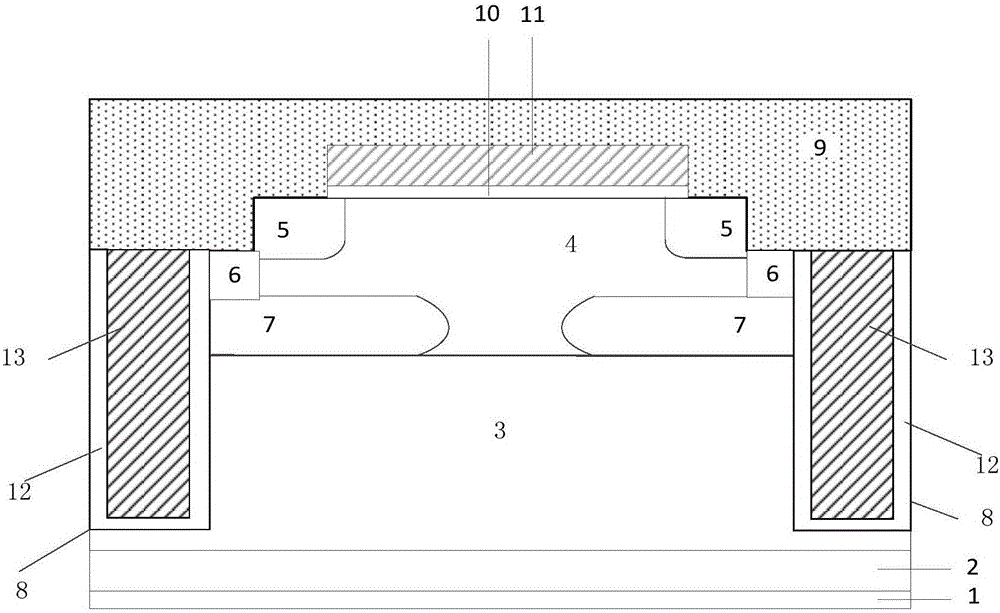

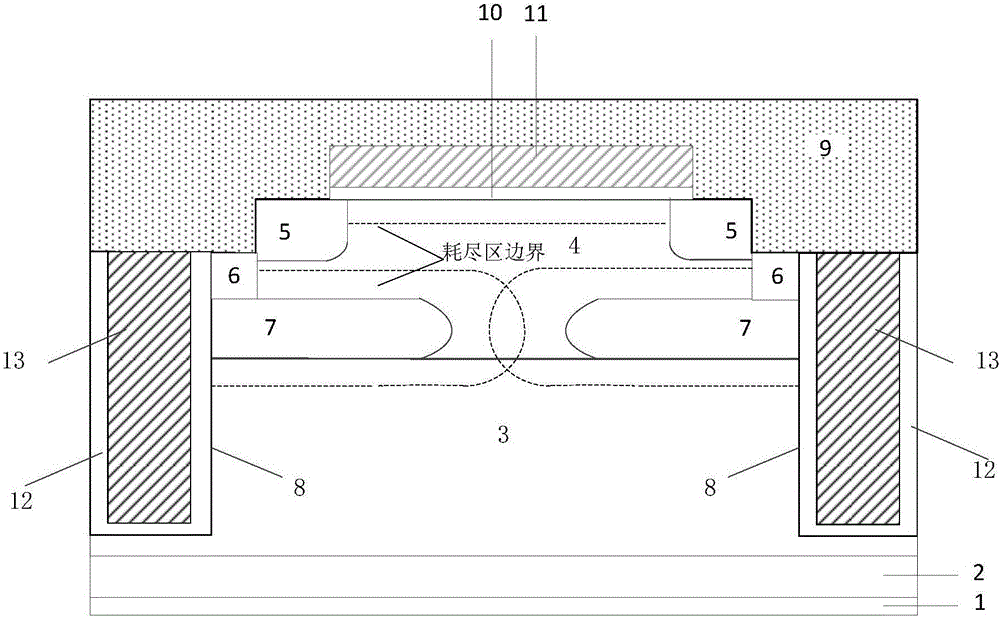

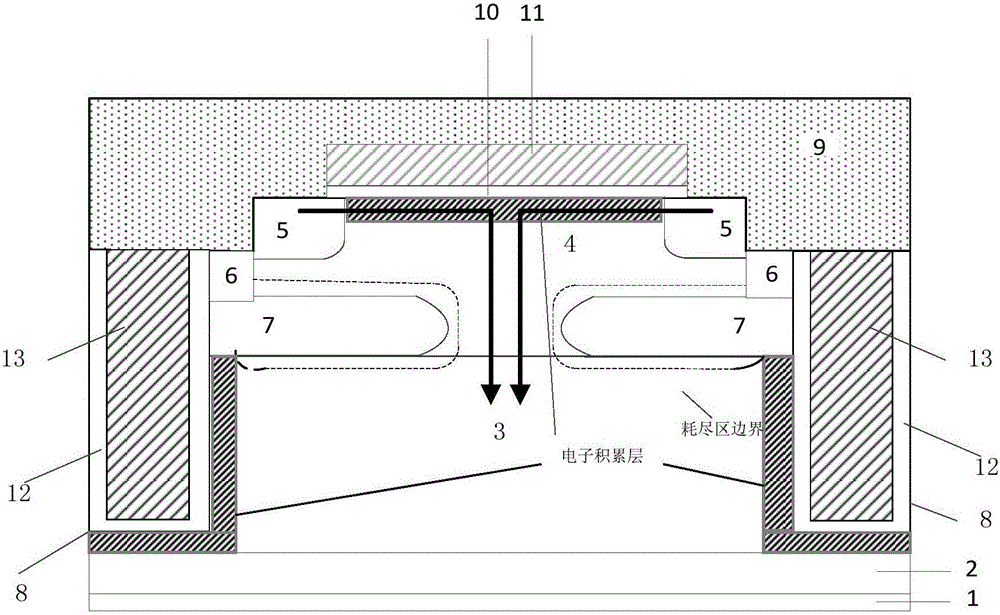

[0019] Such as figure 1 As shown, the metal oxide semiconductor diode of this example includes an anode electrode 9, an N-doped region 4, an N-type region 3, an N-type heavily doped single crystal silicon substrate 2, and a cathode stacked sequentially from top to bottom. Electrode 1; both ends of the anode electrode 9 extend vertically downward into the N-doped region 4, and there is an N-type heavily doped region 5 between the N-doped region 4 and the downwardly extending part of the anode electrode 9; The upper surface of the N-doped region 4 between the N-type heavily doped regions 5 on both sides has a planar gate structure, and the planar gate structure is located in the anode electrode 1, and the planar gate structure includes a gate oxide layer 10 and is located in the oxide The polysilicon gate electrode 11 on the upper surface of the layer 10, the lower surface of the oxide layer 10 is in contact with the upper surface of a part of the N-type heavily doped region 5; ...

Embodiment 2

[0032] Such as Figure 6 As shown, the structure of this example is based on Example 1, but the shape of the polysilicon 13 is changed. The shape of the polysilicon 13 is wide at the top and narrow at the bottom, which is an inverted trapezoid, and the oxide layer at the bottom of the groove 8 is thicker than that of the embodiment 1. The working principle of this example is similar to that of Example 1, which can further prevent the breakdown at the bottom corner of the slot 8 and increase the reverse blocking withstand voltage.

[0033] Taking Example 1 as an example, the structure of the present invention can be prepared by the following method, and the process steps are:

[0034] 1. Monocrystalline silicon preparation. An N-type heavily doped single crystal silicon substrate 2 is used, and the crystal orientation is .

[0035] 2. Epitaxial growth. An N-type epitaxial layer with a certain thickness and doping concentration is grown by methods such as vapor phase epitaxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com