Adhesive for lithium ion batteries and preparation method of adhesive for lithium ion batteries

A lithium-ion battery and adhesive technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large environmental pollution, poor electrical conductivity, and poor mechanical properties of the adhesive, and achieve good toughness and good performance. The effect of application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

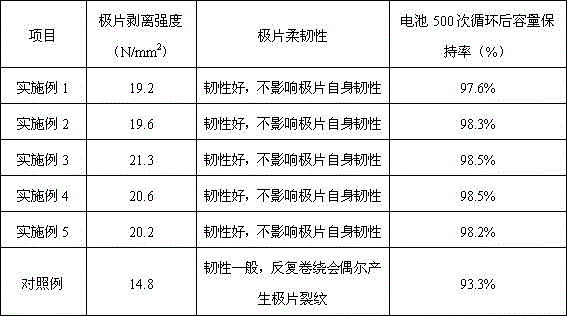

Examples

Embodiment 1

[0017] An adhesive for lithium-ion batteries, the components include in parts by weight: 5 parts of ethyl cyanoacrylate, 2 parts of cyanoethylethylenediamine, 1 part of citric acid, 1 part of polyethyleneimine, modified 15 parts of permanent polyacrylate mixture, 1 part of titanate coupling agent, 0.5 part of ammonium persulfate initiator.

[0018] In the above components, the preparation method of the modified polyacrylate mixture is as follows:

[0019] Add 20 parts by weight of polyacrylate, 2 parts of polyvinyl alcohol, and 3 parts of dimethyl diallyl ammonium chloride into the reaction kettle for mixing. The mixing temperature is 80°C and the mixing time is 10 minutes. , to obtain a modified polyacrylate mixture.

[0020] The preparation method of the binder for the above lithium ion battery, the steps are as follows:

[0021] Step 1, taking each component according to parts by weight;

[0022] Step 2: Add ethyl 2-cyanoacrylate, cyanoethylethylenediamine, citric acid, ...

Embodiment 2

[0024] An adhesive for lithium-ion batteries, the components include in parts by weight: 6 parts of ethyl cyanoacrylate, 4 parts of cyanoethylethylenediamine, 2 parts of citric acid, 1 part of polyethyleneimine, modified 17 parts of permanent polyacrylate mixture, 2 parts of titanate coupling agent, 0.6 parts of ammonium persulfate initiator.

[0025] In the above components, the preparation method of the modified polyacrylate mixture is as follows:

[0026] Add 23 parts of polyacrylate, 4 parts of polyvinyl alcohol, and 4 parts of dimethyl diallyl ammonium chloride in parts by weight into the reaction kettle for mixing. The mixing temperature is 85°C and the mixing time is 15 minutes. , to obtain a modified polyacrylate mixture.

[0027] The preparation method of the binder for the above lithium ion battery, the steps are as follows:

[0028] Step 1, taking each component according to parts by weight;

[0029] Step 2: Add ethyl 2-cyanoacrylate, cyanoethylethylenediamine, c...

Embodiment 3

[0031] An adhesive for lithium ion batteries, the components include in parts by weight: 8 parts of ethyl 2-cyanoacrylate, 5 parts of cyanoethylethylenediamine, 2 parts of citric acid, 2 parts of polyethyleneimine, modified 17 parts of permanent polyacrylate mixture, 3 parts of titanate coupling agent, 0.7 parts of ammonium persulfate initiator.

[0032] In the above components, the preparation method of the modified polyacrylate mixture is as follows:

[0033] Add 28 parts by weight of polyacrylate, 7 parts of polyvinyl alcohol, and 4 parts of dimethyl diallyl ammonium chloride into the reactor for mixing. The mixing temperature is 90°C and the mixing time is 16 minutes. , to obtain a modified polyacrylate mixture.

[0034] The preparation method of the binder for the above lithium ion battery, the steps are as follows:

[0035] Step 1, taking each component according to parts by weight;

[0036] Step 2, add 2-ethyl cyanoacrylate, cyanoethyl ethylenediamine, citric acid, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com