Method for producing biological protein feed through mixed solid fermentation of yeast production wastewater and rapeseed meal by using composite strain

A technology of yeast wastewater and mixed materials, which is applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve the problems of usage and dosage discount, achieve good product quality, strong acid production ability, and promote intestinal microbiology The effect of ecological balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

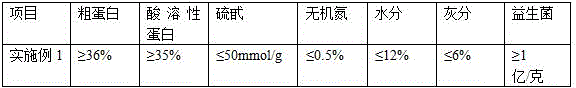

Embodiment 1

[0031] (1) Mixing and inoculation of raw and auxiliary materials

[0032] Prepare 1200kg of raw material rapeseed meal, its water content is 10%, the rapeseed meal protein is controlled between 36%-40%, and the auxiliary material is yeast wastewater, that is, the fermentation wastewater after the yeast is separated in yeast production, with a water content of 60-65% , with a weight of 800kg, wherein the protein content in the yeast wastewater is between 15% and 20%, and the inorganic nitrogen is controlled within 1.5%. Fully mix rapeseed meal and yeast wastewater, adjust the water content of the mixed material to 35%-40%, and the mixing uniformity of the material is less than 10%;

[0033] Weigh 4 kg of Bacillus subtilis (the number of live bacteria is not less than 20 billion / g), 4 kg of Candida utilis (the number of live bacteria is not less than 20 billion / g) and 2 kg of lactic acid bacteria (the number of live bacteria is not less than 10 billion / g); then use 1%-2% glucos...

Embodiment 2

[0042] (1) Mixing and inoculation of raw and auxiliary materials

[0043] Prepare 1100kg of raw rapeseed meal with a water content of 12%. The auxiliary material is concentrated yeast water with a water content of 65% and a weight of 900kg. Fully mix the rapeseed meal with yeast wastewater, and adjust the water content of the mixed material to 35%-40% , the material mixing uniformity is less than 10%;

[0044] Weigh 3.6 kg of Bacillus subtilis (the number of live bacteria is not less than 20 billion / g), 3.6 kg of Candida utilis (the number of live bacteria is not less than 20 billion / g) and 2.0 kg of lactic acid bacteria (the number of live bacteria is not less than 10 billion / g); then use 1%-2% glucose water for activation and cultivation for half an hour, and add it evenly into the mixed material by means of water flow.

[0045] (2) fermentation

[0046]Box-type fermentation is adopted, with a stack height of 1 meter, 1.5-2 tons of material per fermentation box, fermentati...

Embodiment 3

[0050] (1) Mixing and inoculation of raw and auxiliary materials

[0051] Prepare 1300kg of raw rapeseed meal, its water content is 10%, the rapeseed meal protein is controlled between 36%-40%, and the auxiliary material is yeast wastewater, that is, the fermentation wastewater after the yeast is separated in yeast production, with a water content of 60-65% , with a weight of 700kg, wherein the protein content in the yeast wastewater is between 15% and 20%, and the inorganic nitrogen is controlled within 1.5%. Fully mix rapeseed meal and yeast wastewater, adjust the water content of the mixed material to 35%-40%, and the mixing uniformity of the material is less than 10%;

[0052] Weigh 3.8 kg of Bacillus subtilis (the number of live bacteria is not less than 20 billion / g), 4.2 kg of Candida utilis (the number of live bacteria is not less than 20 billion / g) and 2 kg of lactic acid bacteria (the number of live bacteria is not less than 10 billion / g); then use 1%-2% glucose wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com