Polyimide nano-foam and preparation method thereof

A polyimide and nano-foam technology, applied in the field of materials, can solve problems such as reduction, and achieve the effects of increasing molar volume, excellent mechanical properties, and increasing Tg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a kind of preparation method of polyimide nano-foam, it is characterized in that, comprises the following steps:

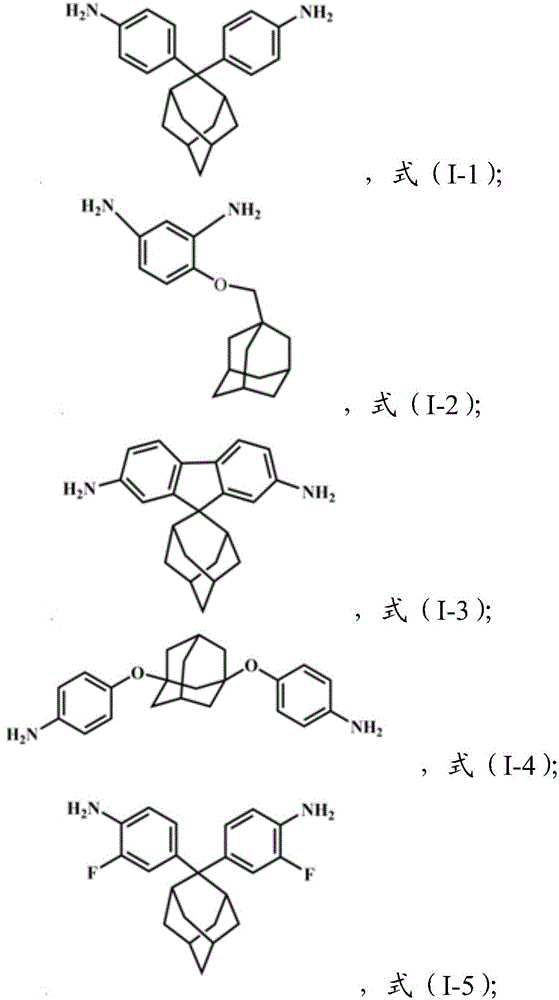

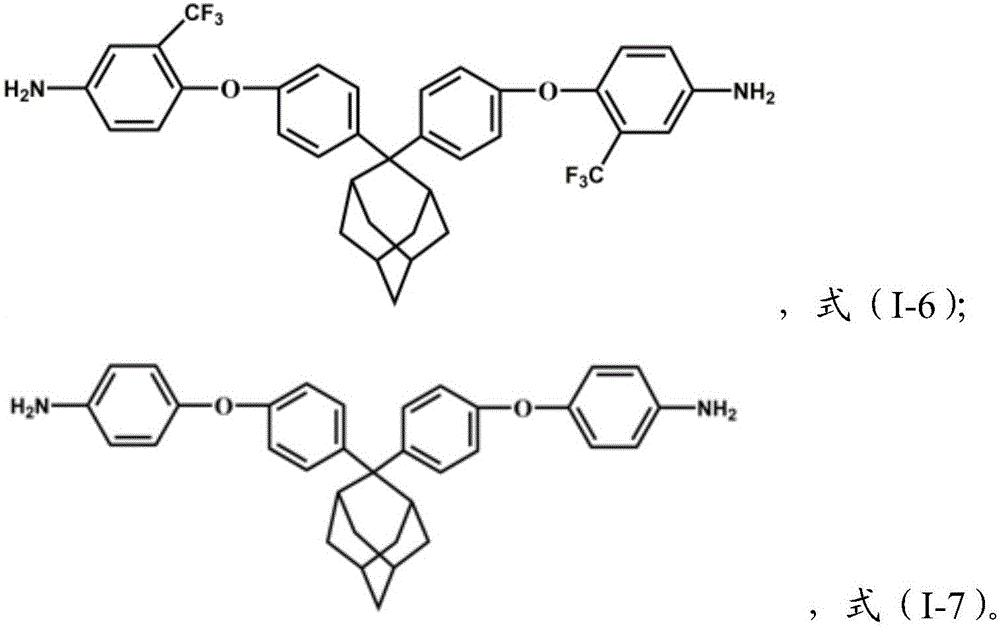

[0033] A) Polymerizing diamine compounds containing adamantyl groups, diamine compounds not containing adamantyl groups, and dianhydride compounds in a solvent to obtain a polyamic acid solution;

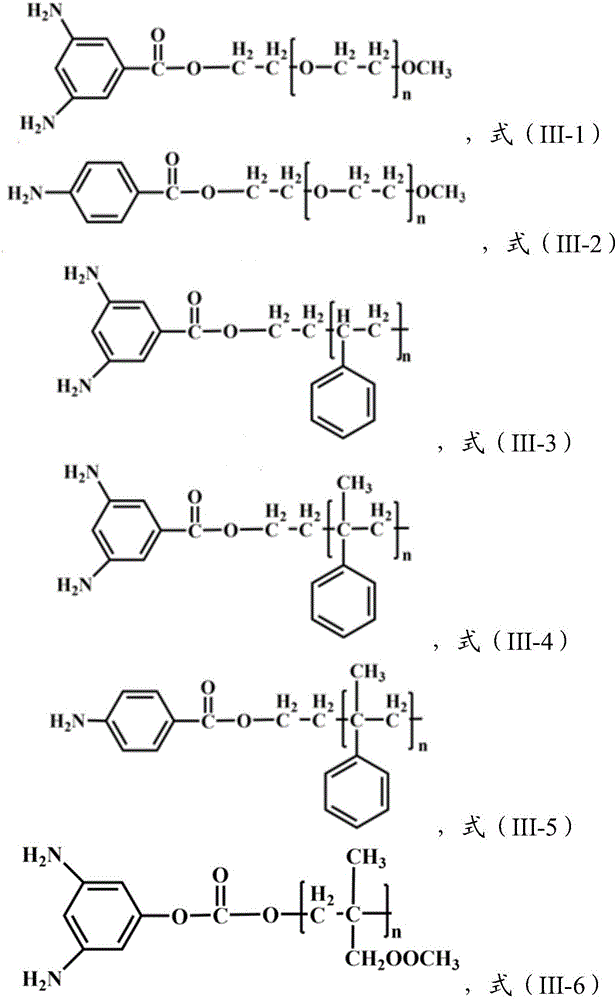

[0034] B) mixing the thermally unstable compound with the polyamic acid solution, followed by uniform dispersion, casting, curing and thermal imidization to obtain a polyimide film;

[0035] C) thermally decomposing the polyimide film to obtain polyimide nano foam.

[0036] In the present invention, the adamantane-containing diamine compound, the adamantane-free diamine compound and the dianhydride compound are polymerized in a solvent to obtain a polyamic acid solution.

[0037] In the present invention, the temperature of the polymerization reaction is preferably 20-40°C, more preferably the reaction is carried out at 20-30°C. The solvent...

Embodiment 1

[0079] Add 15.924g (0.05mol) of 2,2'-bis(4-aminophenyl)adamantane (I-1) into 340ml of N,N'-dimethylacetamide solution, stir and dissolve, then add 10.01g ( 0.05mol) 4,4'-diaminodiphenyl ether, stirred and dissolved, then added 31.021g (0.1mol) 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride, and stirred at room temperature for 24 hours to obtain To the polyamic acid solution, 8.543 g of polyethylene glycol (III-10) with an average molecular weight of 600 was added and dispersed uniformly by ultrasonic to obtain a mixed solution with a solid content of 15%. The mixed solution was cast on the substrate, and cured for 10 h at a humidity of 30% and a temperature of 80° C. to obtain a polyamic acid film. The polyamic acid film was placed in a heating device under nitrogen, and the temperature was raised from room temperature to 300° C. at a rate of 3° C. / min, and kept for 1 hour to obtain a polyimide film.

[0080] The above polyimide film was raised from 50°C to 100°C at a h...

Embodiment 2

[0082]Add 15.924g (0.05mol) of 2,2'-bis(4-aminophenyl)adamantane (I-1) into 350ml of N,N'-dimethylacetamide solution, stir and dissolve, then add 10.01g ( 0.05mol) 4,4'-diaminodiphenyl ether, after stirring and dissolving, add 2.907g (III-1) of polyethylene glycol diaminobenzoate (III-1) with an average molecular weight of 750, add 3 , 32.223g (0.1039mol) of 3′,4,4′-diphenyl ether tetracarboxylic dianhydride was stirred at room temperature for 24 hours to obtain a polyamic acid solution. The polyamic acid solution was cast onto a glass sheet, and cured for 10 h at a humidity of 20% and a temperature of 100° C. to obtain a polyamic acid film. The polyamic acid film was placed in a heating device under nitrogen, raised from room temperature to 300°C at a rate of 5°C / min, and kept for 0.5h to obtain a polyimide film.

[0083] The above polyimide film was raised from room temperature to 250°C at a heating rate of 1°C / min in an air atmosphere, and kept for 4 hours, and then raised...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com