Multi-active functional group coating fortifier and preparing method thereof

A technology of active functional groups and reinforcing agents, which is applied in the direction of water repellent addition, fiber raw material treatment, textiles and papermaking, etc., can solve the problems of affecting cross-linking performance, coating storage performance, limited application, high cost, etc., and achieve excellent wet friction resistance, Effects of paper quality improvement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

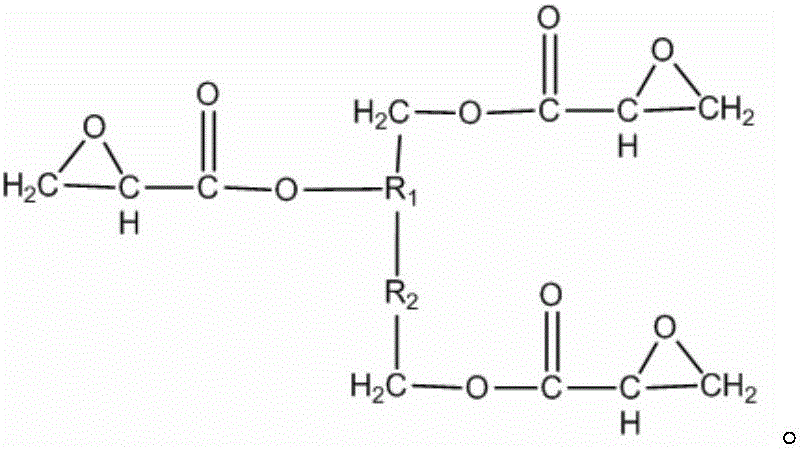

Method used

Image

Examples

Embodiment 1

[0031] Add 1 mole of propylene glycol, 2.2 moles of acrylic acid, 8g of p-toluenesulfonic acid catalyst, 3g of pre-activated superabsorbent resin, raise the temperature to 105-110°C, and start the esterification and dehydration reaction for about 6 hours. When the theoretical value is reached, the temperature is lowered to 50° C., the solvent isopropanol is added, the catalyst TS-β molecular sieve is added, and tert-butyl hydroperoxide is added dropwise (the amount added is 1.5 times the mole number of acrylic acid). After the dropwise addition, keep it warm for 5 hours, let it stand still, separate the unreacted water phase, evaporate the solvent phase at 120°C, remove the insoluble matter by filtration, and finally obtain the target substance.

Embodiment 2

[0033] Add 1 mole of diethylene glycol, 2.5 moles of acrylic acid, 3g of phosphotungstic acid, 120g of toluene, and raise the temperature to 110-120°C to start the esterification and dehydration reaction. The reaction lasts about 5 hours. When the theoretical value is reached, cool down to 35°C, add distilled toluene, water, surfactant CTAB, catalyst quaternary ammonium phosphotungstic acid, and drop hydrogen peroxide (1.2 times the mole number of enoic acid). After the dropwise addition, keep warm for 5 hours, separate the unreacted water phase, distill the product again, distill out the solvent phase at 120-130°C, remove the insoluble matter by filtration, and finally obtain the target substance.

Embodiment 3

[0035] Add 1 mole part of diethylene glycol to the reaction kettle, add 2.5 mole parts of undecylenic acid, then add 3 g of immobilized phosphotungstic acid, 120 g of xylene as a solvent, raise the temperature to 110 ° C, and start the esterification and dehydration reaction of about 6h. Cool down to 50°C, add the water and xylene mixture that came out before, and add 8 g of catalyst phosphotungstic heteropolyacid quaternary ammonium salt, add OP-10, and dropwise add hydrogen peroxide (2 times the mole number of enoic acid). After the dropwise addition, keep warm for 6 hours, then stand still to separate the water phase, evaporate the solvent phase at 140-150°C, remove insoluble matter by filtration, and finally obtain the target substance.

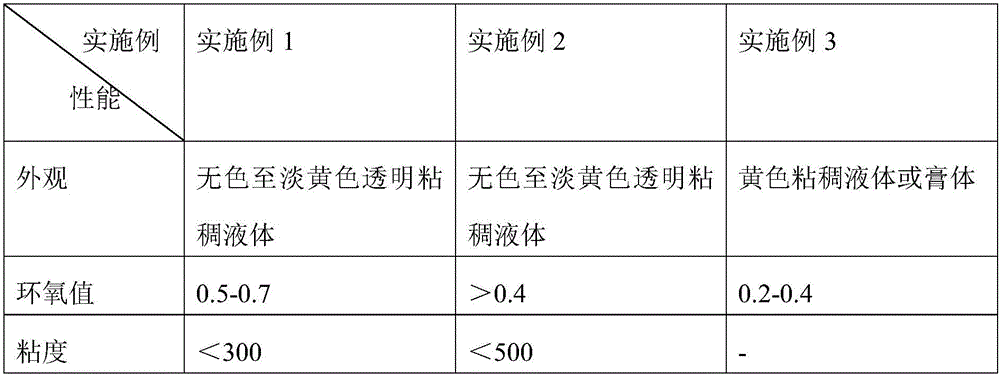

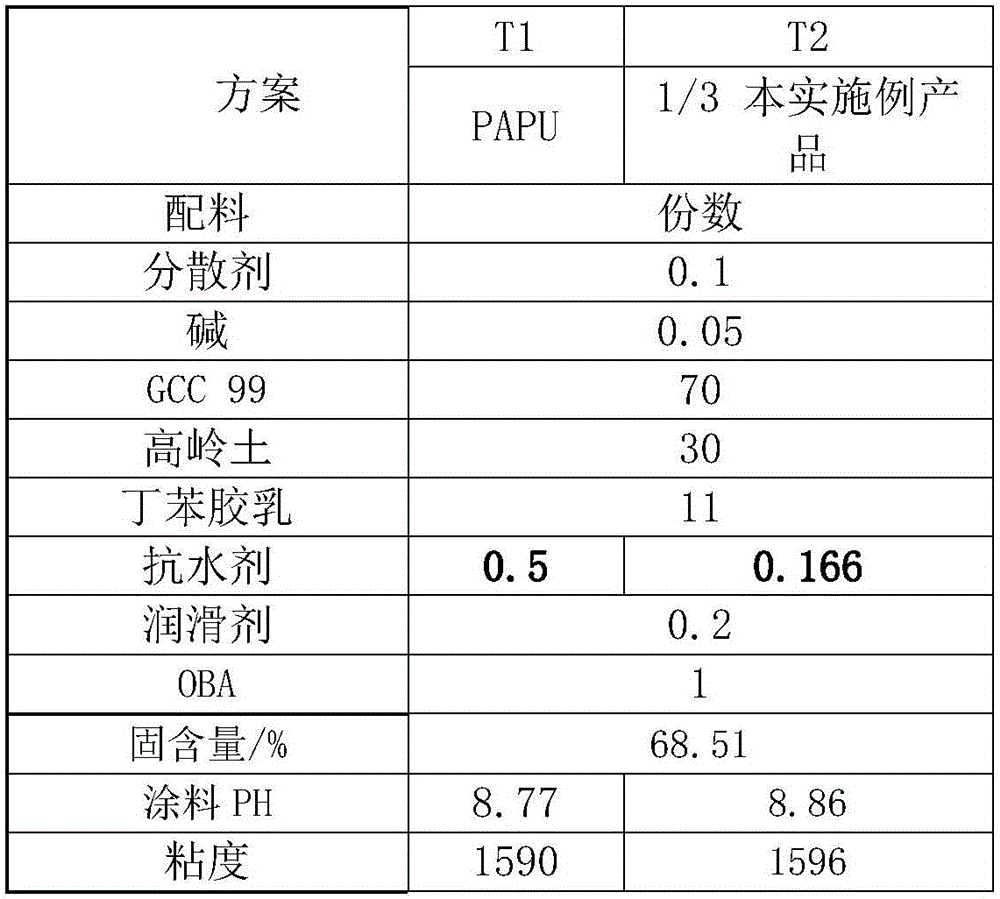

[0036] Above-mentioned embodiment 1~3 obtains the performance test result of product as following table:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com