Sintering flue gas synchronous desulfurization and denitration process based on optical-electric type fenton coupling regeneration

A technology for sintering flue gas, desulfurization and denitrification, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of expensive EDTA and cysteine, high cost pressure, etc. The effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

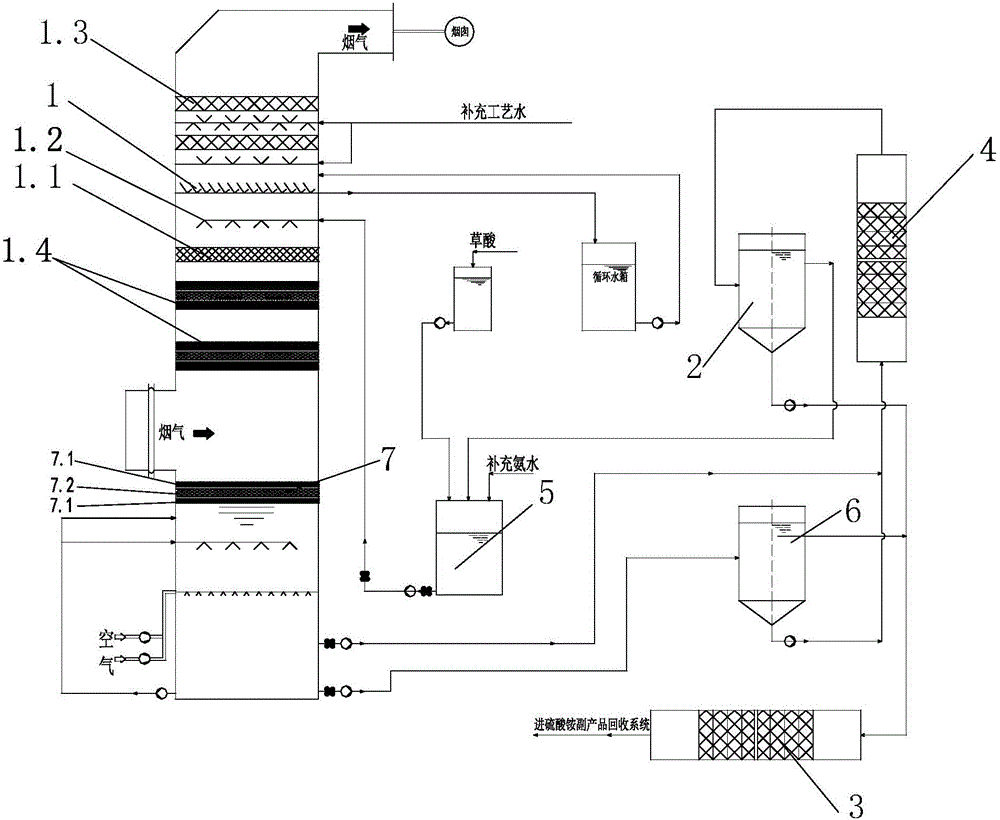

[0042] Process example:

[0043] see figure 1 , in a sintering flue gas desulfurization system, the sintering flue gas volume is about 14-16Nm 3 / h, SO 2 Concentration: 500~800mg / Nm 3 , NOx concentration (mainly NO): 300~400mg / Nm 3 , particulate matter (which contains elemental iron) concentration: 30~50mg / Nm 3 . The desulfurization adopts the ammonia water absorption process in the packed tower.

[0044] The physical parameters and related composition of the absorption liquid are as follows:

[0045] pH value: 5.0~5.5;

[0046] Ammonium sulfate concentration: 20-45% (mass percentage);

[0047] Total concentration of Fe(II)+Fe(III): 0.045~0.15mol / L;

[0048] Concentration of oxalate ion: 0.27~0.9mol / L;

[0049] Absorption liquid temperature: 50-55°C.

[0050] The flue gas is introduced into the middle of the absorption tower 1, and in the absorption tower 1, the flue gas flows from bottom to top through at least one photochemical reaction layer 1.4 (two layers in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com