Surfactant containing o-nitrobenzyl ester photodegradation group, and preparation method thereof

A technology of o-nitrobenzyl ester and surfactant, applied in the field of new light-controlled surface active molecules and its preparation, can solve the problems of low efficiency, long reaction time, cumbersome steps, etc., to improve efficiency and shorten complex reaction process , Improve the effect of reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

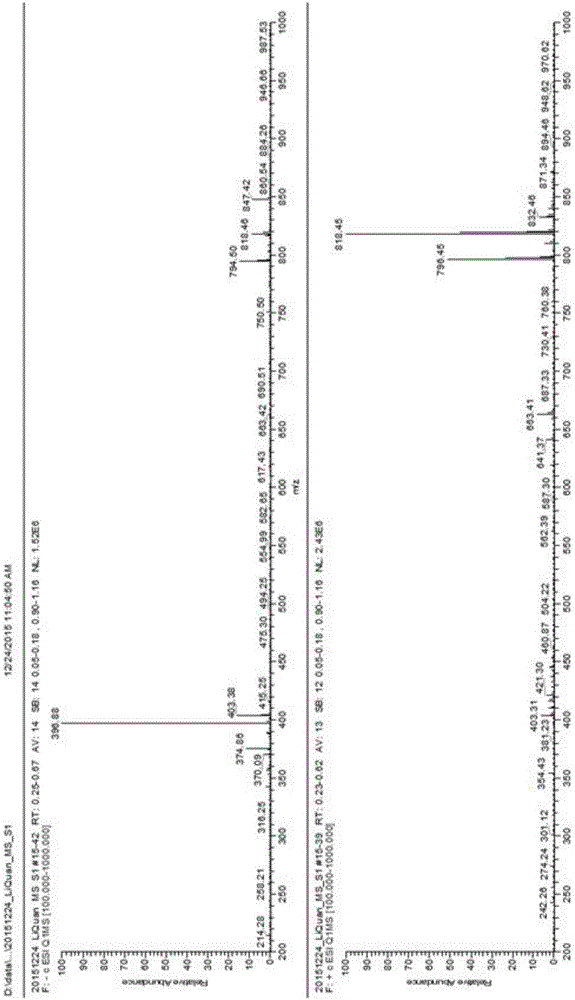

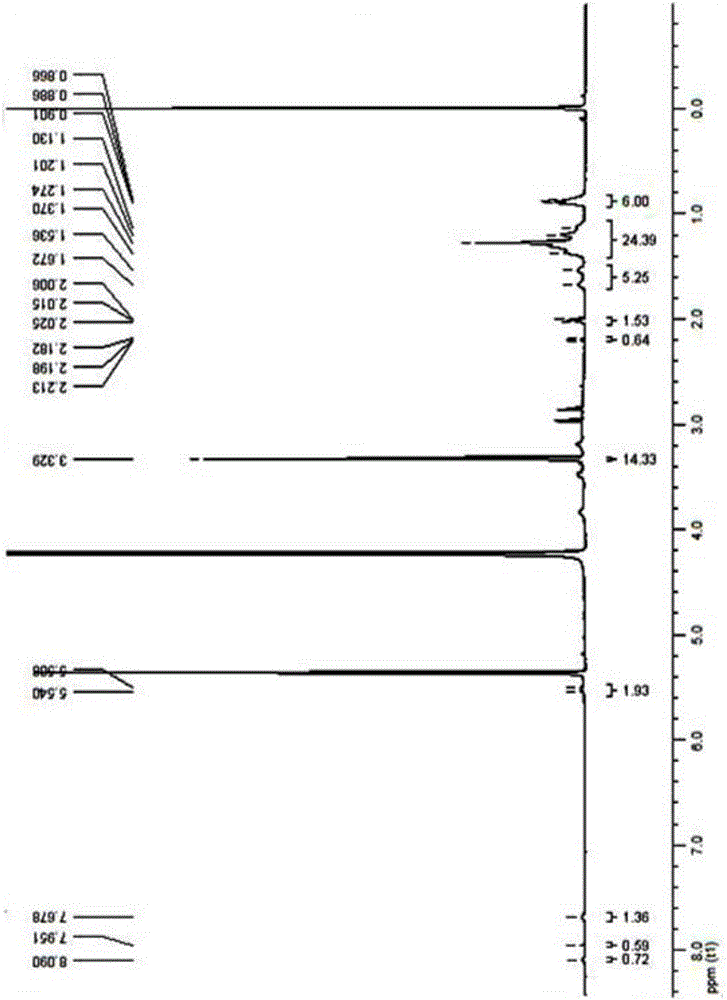

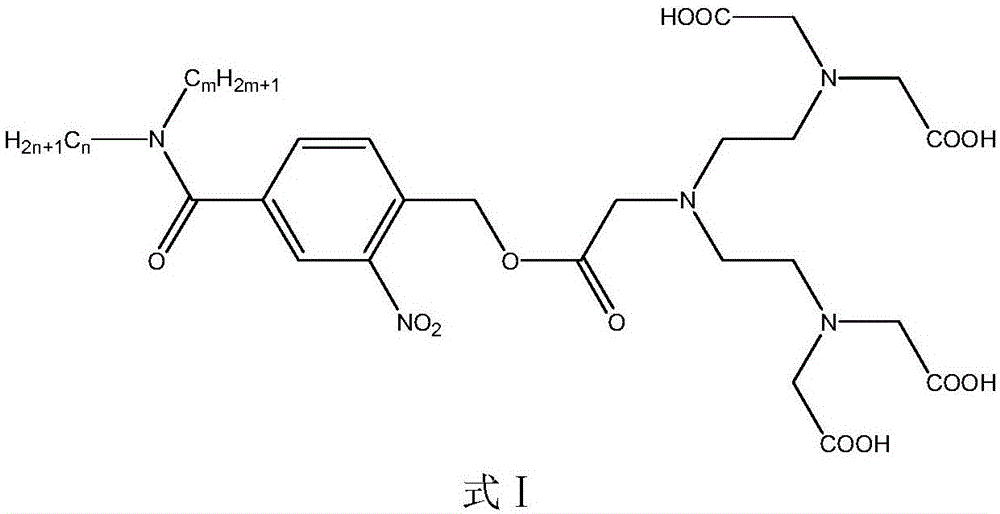

[0041] Embodiment 1 The synthesis of photodegradable surfactant (4-diethylenetriaminepentaacetate)-3-nitro-N,N-dioctylbenzamide:

[0042] (1) Synthesis of diethylene triamine pentaacetic anhydride

[0043] Weigh 3.98g (0.01mol) of diethylenetriaminepentaacetic acid and a 100mL single-necked flask, add 4mL of acetic anhydride and 5mL of pyridine in sequence, raise the temperature to 65°C under nitrogen protection, and react for 24h. Suction filtration after the reaction was completed to obtain a white solid powder. Melting point: 178°C-184°C

[0044] (2) Synthesis of intermediates of N,N-dioctylbenzamide brominated derivatives

[0045]Take 1g (0.004mol) of 4-bromomethyl-3-nitrobenzoic acid in a 100mL three-necked flask, add 10mL of thionyl chloride dropwise under magnetic stirring, and reflux for 3 hours. sulfone. Add 0.96g (0.004mol) di-n-octylamine dropwise to the three-necked flask. After the dropwise addition, add 0.5g (0.004mol) potassium carbonate, react at 40°C for 1...

Embodiment 2

[0052] Example 2 Synthesis of photodegradable surfactant (4-diethylenetriaminepentaacetate)-3-nitro-N,N-didecylbenzamide:

[0053] (1) Synthesis of diethylene triamine pentaacetic anhydride

[0054] Same as Example 1

[0055] (2) Synthesis of N,N-Didecylbenzamide Brominated Derivative Intermediates

[0056] Take 1g (0.004mol) of 4-bromomethyl-3-nitrobenzoic acid and a 100mL three-necked flask, add 10mL of thionyl chloride dropwise under magnetic stirring, and reflux for 4 hours. sulfone. Add 1.19g (0.004mol) di-n-decylamine dropwise to the three-necked flask. After the dropwise addition, add 0.5g (0.004mol) potassium carbonate, react at 50°C for 15h, stop the reaction, add an appropriate amount of deionized water, separate the liquid, and the organic layer Dry it with anhydrous sodium sulfate, and use a 40:1 volume ratio mixture of dichloromethane and methanol as the eluent for column separation to obtain a pale yellow oily liquid. Yield 62.1%.

[0057] (3) Synthesis of (...

Embodiment 3

[0059] Example 3 Synthesis of photodegradable surface active molecule (4-diethylenetriaminepentaacetate)-3-nitro-N,N-behenylbenzamide:

[0060] (1) Synthesis of diethylene triamine pentaacetic anhydride

[0061] Same as Example 1

[0062] (2) Synthesis of intermediates of brominated derivatives

[0063] Take 1g (0.004mol) of 4-bromomethyl-3-nitrobenzoic acid and a 100mL three-necked flask, add 10mL of thionyl chloride dropwise under magnetic stirring, and reflux for 3 hours. sulfone. Add 1.47g (0.004mol) didodecylamine dropwise to the three-necked flask. After the dropwise addition, add 0.5g (0.004mol) potassium carbonate, react at 40°C for 12 hours, stop the reaction, add an appropriate amount of deionized water, separate the liquid, and the organic layer Dry it with anhydrous sodium sulfate, and use a 40:1 volume ratio mixture of dichloromethane and methanol as the eluent for column separation to obtain a pale yellow oily liquid. Yield 46.5%.

[0064] (3) Synthesis of (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com