Chromate-free passivation treating agent for nickel-plated surface and treating process

A chromium-free passivation and treatment agent technology, applied in the coating process of metal materials, etc., can solve the problems of chromate passivation treatment technology limitations, human health and ecological environment hazards, etc., and achieve simple environmental protection and corrosion resistance and oxidation resistance improvement, good electrical conductivity and weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

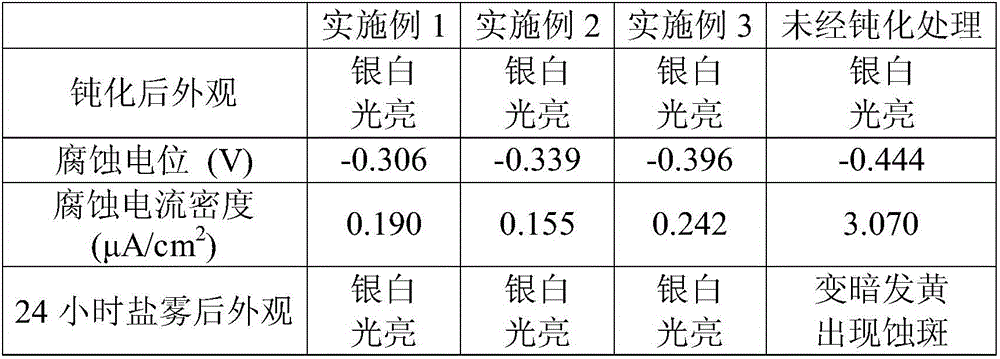

Examples

Embodiment 1

[0023] A kind of nickel-plated surface chromium-free passivation treatment agent of the present embodiment is formulated according to the parts by weight of the following components: 10 parts of sodium hydroxide, 20 parts of potassium persulfate, 5 parts of sodium silicate, 10 parts of sodium phosphate , 3 parts of sodium carbonate, 52 parts of deionized water.

[0024] The above-mentioned nickel-plated surface chromium-free passivation treatment agent is made according to the following steps:

[0025] (1) Sodium hydroxide is poured into deionized water, and stirred at normal temperature and pressure until completely dissolved;

[0026] (2) Sodium phosphate, sodium silicate and sodium carbonate are poured into the solution obtained in step (1), and stirred at normal temperature and pressure until completely dissolved;

[0027] (3) Pour potassium persulfate into the solution obtained in step (2), and stir at normal temperature and pressure until completely dissolved to obtain ...

Embodiment 2

[0031] A chromium-free passivation treatment agent for nickel-plated surfaces of this embodiment is prepared according to the parts by weight of the following components: 10 parts of sodium hydroxide, 20 parts of potassium persulfate, 5 parts of sodium silicate, and 15 parts of sodium tungstate 3 parts, 3 parts of sodium carbonate, 47 parts of deionized water.

[0032] The above-mentioned nickel-plated surface chromium-free passivation treatment agent is made according to the following steps:

[0033] (1) Sodium hydroxide is poured into deionized water, and stirred at normal temperature and pressure until completely dissolved;

[0034] (2) Pour sodium tungstate, sodium silicate and sodium carbonate into the solution obtained in step (1), and stir at normal temperature and pressure until completely dissolved;

[0035] (3) Pour potassium persulfate into the solution obtained in step (2), and stir at normal temperature and pressure until completely dissolved to obtain the chromi...

Embodiment 3

[0039] A kind of nickel-plated surface chromium-free passivation treatment agent of the present embodiment is formulated according to the parts by weight of the following components: 10 parts of sodium hydroxide, 20 parts of potassium persulfate, 5 parts of sodium silicate, 3 parts of sodium carbonate , 62 parts of deionized water.

[0040] The above-mentioned nickel-plated surface chromium-free passivation treatment agent is made according to the following steps:

[0041] (1) Sodium hydroxide is poured into deionized water, and stirred at normal temperature and pressure until completely dissolved;

[0042] (2) Sodium silicate and sodium carbonate are poured into the solution obtained in step (1), and stirred at normal temperature and pressure until fully dissolved;

[0043] (3) Pour potassium persulfate into the solution obtained in step (2), and stir at normal temperature and pressure until completely dissolved to obtain the chromium-free passivation treatment agent.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com