Toothpaste and preparation method thereof

A technology for toothpaste and active additives, applied in dentistry, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of ineffective teeth whitening, adverse reactions in the oral cavity and teeth, etc. effects of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

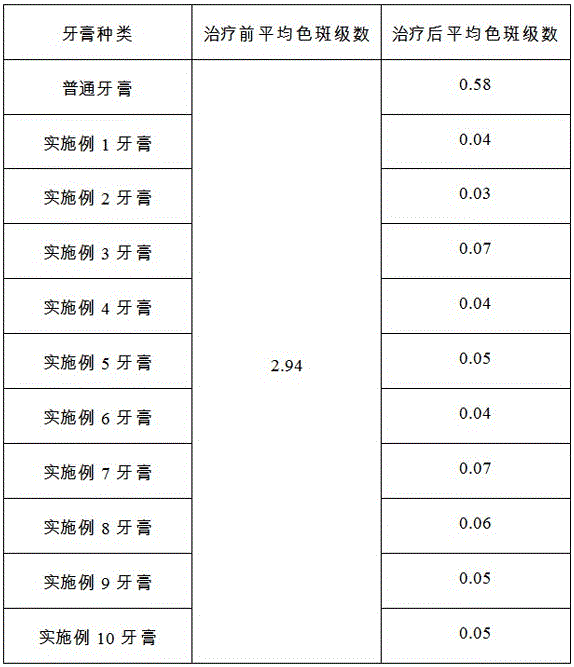

Examples

Embodiment 1

[0026] A kind of toothpaste, the raw material composition of this toothpaste:

[0027] Calcium carbonate: 200 g, glycerin: 200 g, sodium lauryl sulfate: 30 g, sodium 2-acyloxy bond sulfonate: 120 g, sodium lauroyl sarcosinate: 80 g, sodium citrate: 20 g, Sodium Alginate: 10 g, Sodium Benzoate: 20 g, Pectin: 30 g, Papaya Extract: 15 g, Licorice Root Extract: 15 g, Grape Extract: 15 g, Pear Extract: 15 g, Bayberry Extract : 15 g, Lychee Extract: 15 g, Water: 200 g.

[0028] Its preparation method comprises the following steps:

[0029] Production step S01 of active additives: remove impurities from papaya, licorice, grapes, pears, red bayberry, and litchi, extract them at 78°C for 23 minutes, decolorize the concentrated solution with activated carbon, and concentrate it into an extract with a relative density of 1.13. Instant active additives;

[0030] Calcium carbonate grinding step S02: Grinding 200 g of calcium carbonate through a grinder to grind the coarse and hard parti...

Embodiment 2

[0034] A kind of toothpaste, the raw material composition of this toothpaste:

[0035]Calcium carbonate: 110 g, glycerin: 150 g, sodium lauryl sulfate: 18 g, sodium 2-acyloxy bond sulfonate: 100 g, sodium lauroyl sarcosinate: 50 g, sodium citrate: 20 g, Sodium Alginate: 9 g, Sodium Benzoate: 5 g, Pectin: 25 g, Active Additives: 90 g, Water: 453 g.

[0036] Its preparation method comprises the following steps:

[0037] The production step S01 of the active additive: removing impurities from the papaya, extracting it at 70°C for 20 minutes, decolorizing the concentrated solution with activated carbon, and concentrating it into an extract with a relative density of 1.10 to obtain the active additive;

[0038] Calcium carbonate grinding step S02: Grinding 110 g of calcium carbonate through a grinder to grind the coarse and hard particles finely so that the calcium carbonate is fine and uniform with a particle size of 10 μm;

[0039] Toothpaste preparation step S03: 150g of glyce...

Embodiment 3

[0042] A kind of toothpaste, the raw material composition of this toothpaste:

[0043] Calcium carbonate: 250 g, glycerin: 200 g, sodium lauryl sulfate: 30 g, sodium 2-acyloxy bond sulfonate: 150 g, sodium lauroyl sarcosinate: 100 g, sodium citrate: 30 g, sodium alginate: 30g, sodium benzoate: 30g, pectin: 30g, active additives: 100g, water: 50g.

[0044] Its preparation method comprises the following steps:

[0045] The production step S01 of the active additive: removing impurities from licorice, extracting at 80°C for 30 minutes, decolorizing the concentrated solution with activated carbon, and then concentrating it into an extract with a relative density of 1.30 to obtain the active additive;

[0046] Calcium carbonate grinding step S02: Grinding 250 g of calcium carbonate with a grinder to grind coarse and hard particles finely so that the calcium carbonate is fine and uniform with a particle size of 15 μm;

[0047] Toothpaste preparation step S03: 200g of glycerin, 50g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com