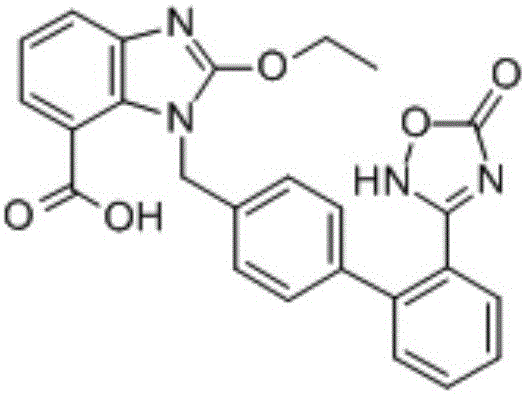

Azilsartan tablets and preparation method thereof

A technology for azilsartan tablets and tablet compression, which is applied in the field of preparation of azilsartan granulation, can solve the problems of low dissolution, low penetration, tediousness, etc., and solve the problems of insufficient tablet hardness, slow disintegration and dissolution, Easy compression molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

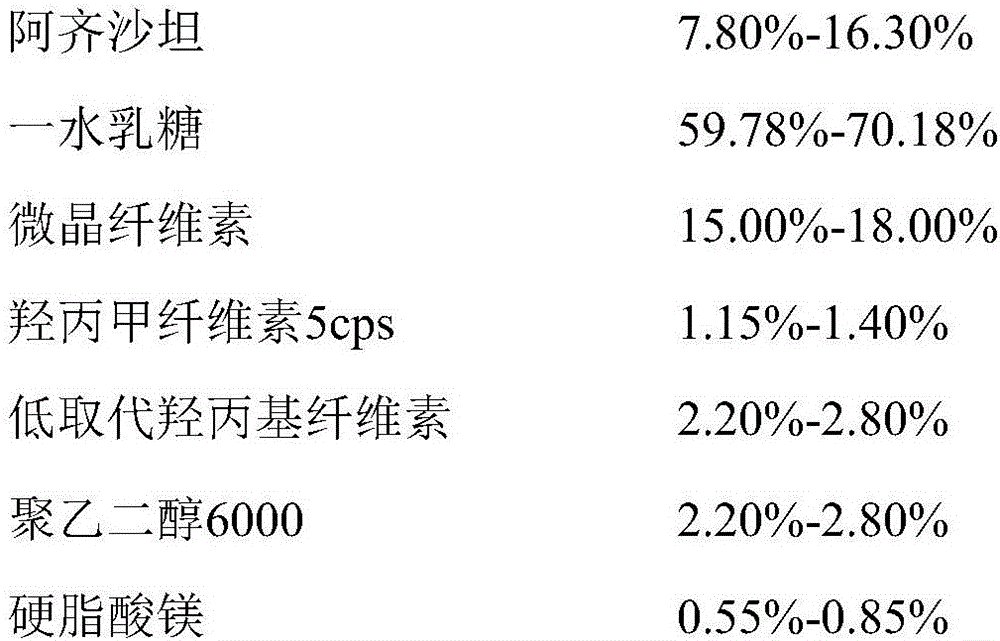

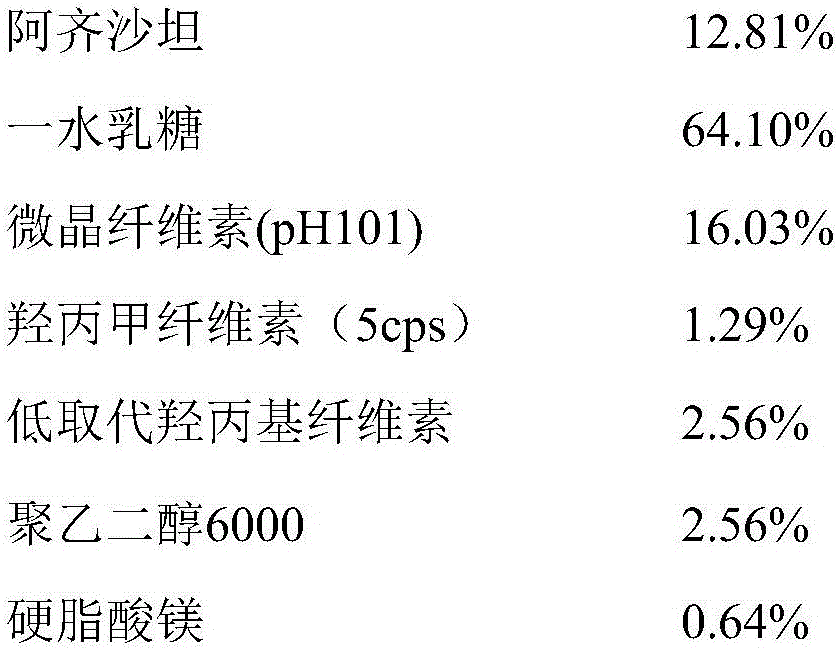

[0036] 10mg tablet specifications:

[0037]

[0038] The preparation method is as follows:

[0039] 1) Micronize the raw material of Azilsartan to a particle size D90≤15μm;

[0040] 2) Lactose monohydrate, microcrystalline cellulose, polyethylene glycol 6000, low-substituted hydroxypropyl cellulose pass through 80 mesh sieve;

[0041] 3) Preparation of adhesive: prepare a 5% solution according to the ratio of hypromellose (5cps): 50% ethanol solution = 5: 100 (W: V);

[0042] 4) Weigh the processed azilsartan, lactose monohydrate, microcrystalline cellulose, and polyethylene glycol 6000 according to the prescription amount, and weigh and mix the low-substituted hydroxypropyl cellulose according to 50% of the prescription amount;

[0043] 5) Put the mixed raw and auxiliary materials into a fluidized bed, and granulate by top spraying. The parameters are as follows:

[0044] Fan frequency (Hz): 25-30

[0045] Inner atomization (bar): 1.8-2.0

[0046] Outer atomization (bar): 2.3-2.6

[0047] I...

Embodiment 2

[0052] 20mg tablet specifications:

[0053]

[0054] The preparation method is as follows:

[0055] 1) Micronize the raw material of Azilsartan to a particle size D90≤15μm;

[0056] 2) Lactose monohydrate, microcrystalline cellulose, polyethylene glycol 6000, low-substituted hydroxypropyl cellulose pass through 80 mesh sieve;

[0057] 3) Preparation of the binder: prepare a 6% solution at the ratio of hypromellose (5cps): 50% ethanol solution = 6: 100 (W: V);

[0058] 4) Weigh the processed azilsartan, lactose monohydrate, microcrystalline cellulose, and polyethylene glycol 6000 according to the prescription amount, and weigh and mix the low-substituted hydroxypropyl cellulose according to 50% of the prescription amount;

[0059] 5) Put the mixed raw and auxiliary materials into a fluidized bed, and granulate by top spraying. The parameters are as follows:

[0060] Fan frequency (Hz): 25-30

[0061] Inner atomization (bar): 1.8-2.0

[0062] Outer atomization (bar): 2.3-2.6

[0063] Inlet air...

Embodiment 3

[0068] 30mg tablet specifications:

[0069]

[0070] The preparation method is as follows:

[0071] 1) Micronize the raw material of Azilsartan to a particle size D90≤15μm;

[0072] 2) Lactose monohydrate, microcrystalline cellulose, polyethylene glycol 6000, low-substituted hydroxypropyl cellulose pass through 80 mesh sieve;

[0073] 3) Preparation of the adhesive: prepare an 8% solution at the ratio of hypromellose (5cps): 50% ethanol solution = 8: 100 (W: V);

[0074] 4) Weigh the processed azilsartan, lactose monohydrate, microcrystalline cellulose, and polyethylene glycol 6000 according to the prescription amount, and weigh and mix the low-substituted hydroxypropyl cellulose according to 50% of the prescription amount;

[0075] 5) Put the mixed raw and auxiliary materials into a fluidized bed, and granulate by top spraying. The parameters are as follows:

[0076] Fan frequency (Hz): 25-30

[0077] Inner atomization (bar): 1.8-2.0

[0078] Outer atomization (bar): 2.3-2.6

[0079] Inlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com