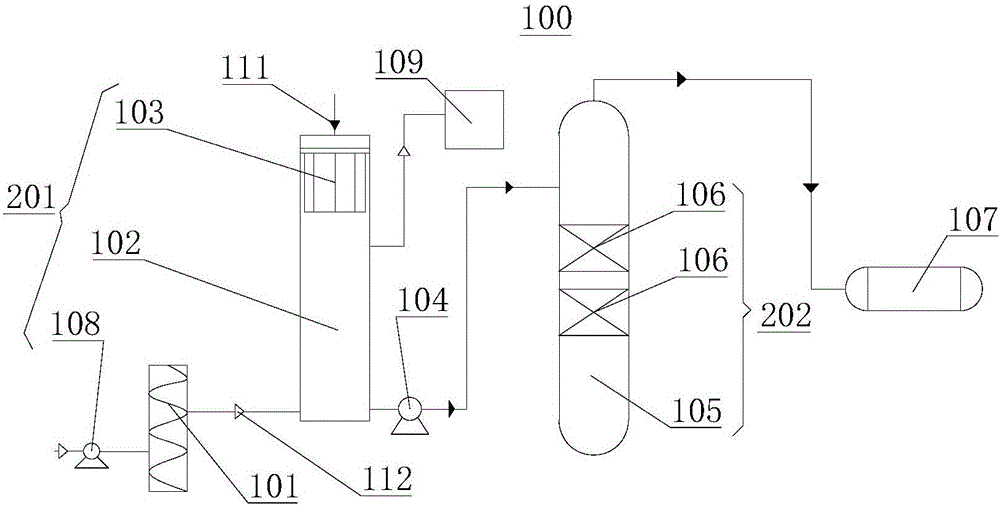

Non-aqueous solvent carbon dioxide capture liquid, method and system

A carbon dioxide and non-aqueous solvent technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as equipment corrosion, high regeneration energy consumption, and absorbent degradation, and achieve corrosion avoidance, low specific heat capacity, and low latent heat of evaporation , The effect of reducing recycling and disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

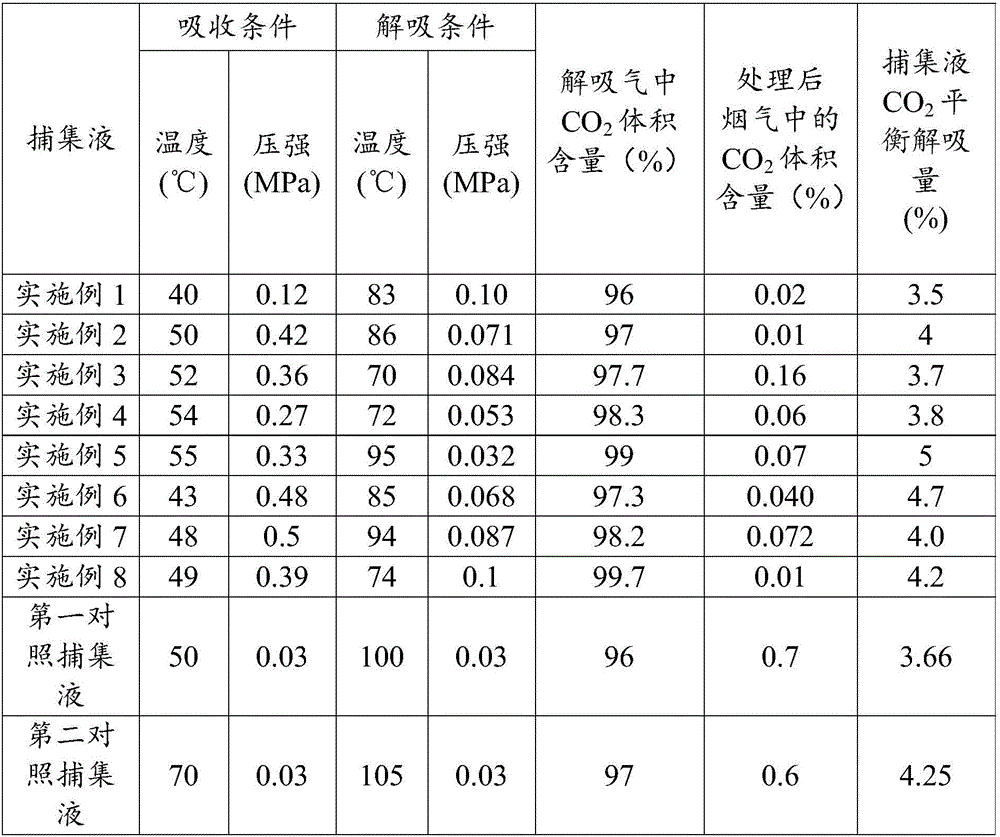

Embodiment 1

[0054] A non-aqueous solvent carbon dioxide capture liquid, comprising the following components by weight percentage: 2kg of 2-amino-2-methyl-1-propanol, 5.5kg of diethanolamine, and 30kg of ethanol. The preparation method of this non-aqueous solvent carbon dioxide capture liquid is as follows: 2-amino-2-methyl-1-propanol and diethanolamine are added to ethanol, and fully stirred to obtain a capture liquid. The desorption temperature of carbon dioxide is 83°C .

Embodiment 2

[0056] A non-aqueous solvent carbon dioxide capture liquid, comprising the following components by weight percentage: 52.6kg of 2-amino-2-methyl-1-propanol, 0.8kg of diethanolamine, and 80kg of ethanol. The production method of the non-aqueous solvent carbon dioxide capture liquid is as follows: 2-amino-2-methyl-1-propanol and diethanolamine are added to ethanol, and fully stirred to obtain a capture liquid, and the desorption temperature of carbon dioxide is 86°C .

Embodiment 3

[0058] A non-aqueous solvent carbon dioxide capture liquid, comprising the following components by weight percentage: 12.8 kg of 2-piperidine ethanol, 1.3 kg of piperazine, and 33 kg of methanol. The preparation method of the non-aqueous solvent carbon dioxide capture liquid is as follows: 2-piperidine ethanol and diethanolamine are added to methanol, and fully stirred to prepare the capture liquid. The desorption temperature of carbon dioxide is 70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com