Porous magnetic spherical material with sewage purification function and preparation method thereof

A spherical, magnetic technology, applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of complex pollutant composition and difficulty in removing polluted soil pollutants, and achieve excellent heavy metal pollutants , The recovery process is simplified, the method is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

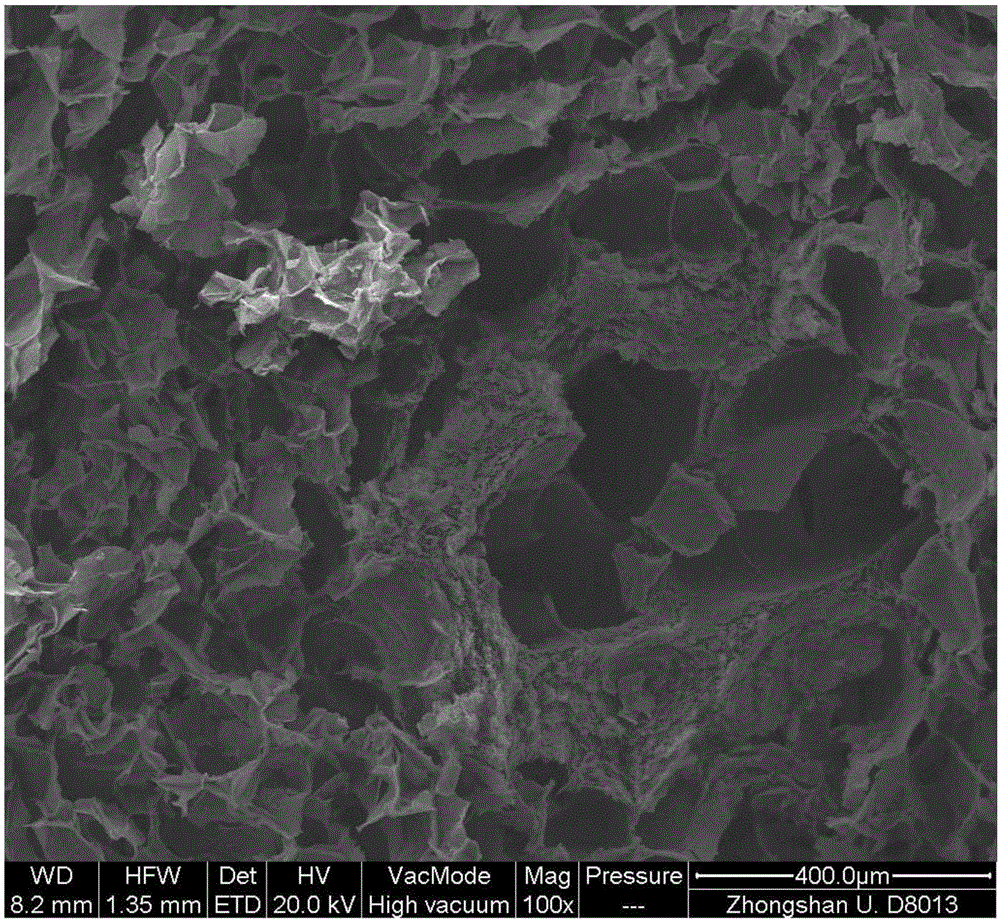

Image

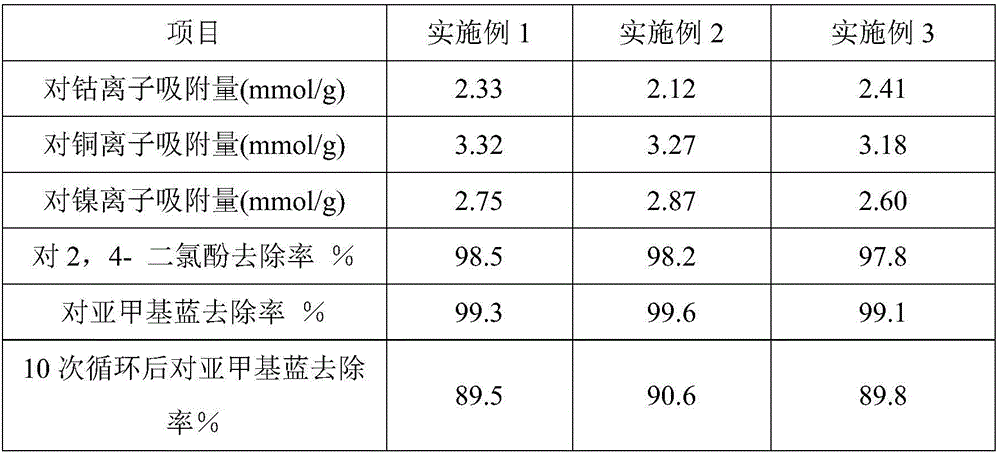

Examples

preparation example Construction

[0031] The preparation method of the porous magnetic spherical material described above comprises the following steps:

[0032] 1) Preparation of nanocomposite magnetic particles: Nano-Fe 3 o 4 The magnetic particles are dispersed in the isopropanol solution of tetrabutyl titanate, and the nano-sized TiO is obtained by magnetic separation after static reaction for 2-72 hours. 2 Nano Fe 3 o 4 nanocomposite magnetic particles;

[0033] 2) Preparation of porous magnetic spherical materials: uniformly disperse the nanocomposite magnetic particles obtained in the previous step in chitosan acetic acid solution, ultrasonically disperse, and drop the dispersed mixture into CuSO 4 Solidify in the solution, filter to get the filter residue;

[0034] After drying the filter residue, disperse it in the glutaraldehyde aqueous solution, treat it at 70-90°C for 3-6 hours, filter the filter residue, remove the excess copper ions in the filter residue, wash it, and then disperse it in wat...

Embodiment 1

[0053] A method for preparing a porous magnetic spherical material with sewage purification function, comprising the following steps:

[0054] 1) Preparation of magnetic nanoparticles: FeCl 2 , FeCl 3 , ammonia, polyvinyl alcohol, and water are added to the hydrothermal reaction kettle at a weight ratio of 1:1.2:0.3:0.1:10. After fully dissolving, seal and lock the hydrothermal reaction kettle and put it in a 180°C oven for static hydrothermal reaction. 5 hours, after cooling, take it out and wash it with magnetic separation to obtain nano-Fe 3 o 4 Magnetic particles; obtained Fe 3 o 4 The size is 50-500nm, and the saturation magnetization is 55-75emu / g.

[0055] 2) Preparation of nanocomposite magnetic particles: TiO 2 coated magnetic Fe 3 o 4 The preparation method of magnetic particle is, with 0.3g nanometer Fe 3 o 4 The magnetic particles are dispersed in tetrabutyl titanate isopropanol solution with a mass concentration of 0.1% w / w, and the nano-sized TiO is obt...

Embodiment 2

[0061] A method for preparing a porous magnetic spherical material with sewage purification function, comprising the following steps:

[0062] 1) Preparation of magnetic nanoparticles: FeCl 2 , FeCl 3 , ammonia, polyvinyl alcohol, and water are added to the hydrothermal reaction kettle at a weight ratio of 1:1.2:0.3:0.1:10. After fully dissolving, seal and lock the hydrothermal reaction kettle and put it in a 180°C oven for static hydrothermal reaction. 5 hours, after cooling, take it out and wash it with magnetic separation to obtain nano-Fe 3 o 4 Magnetic particles; obtained Fe 3 o 4 The size is 50-500nm, and the saturation magnetization is 55-75emu / g.

[0063] 2) Preparation of nanocomposite magnetic particles: TiO 2 coated magnetic Fe 3 o 4 The preparation method of the magnetic particles is, the nano-Fe 3 o 4 The magnetic particles are dispersed in tetrabutyl titanate isopropanol solution with a mass concentration of 5% w / w, and after static reaction for 8 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com