Modified bean dreg adsorbent, preparation method and application thereof

A soybean dregs and adsorbent technology, applied in the field of modified soybean dregs adsorbent and its preparation, can solve the problems of deepening color of wastewater, small specific surface area, reduced specific surface area, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

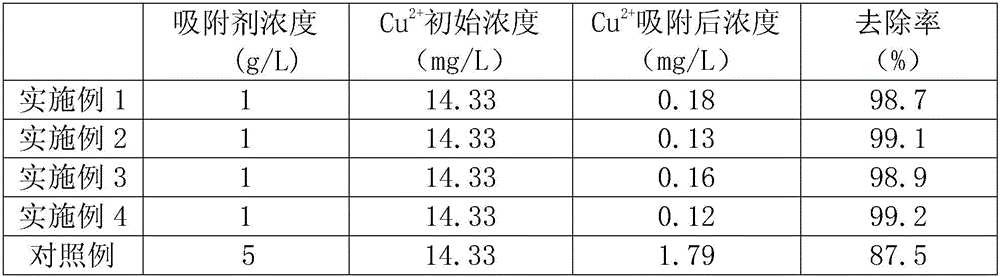

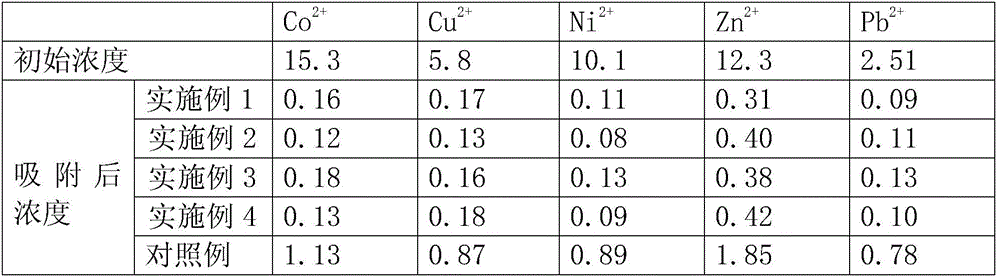

Examples

Embodiment 1

[0022] 1) Grinding soybean dregs to 60 mesh, drying to obtain soybean dregs powder;

[0023] 2) Add 1g of soybean dregs powder and 100ml of 2mol / L silicic acid into the three-necked flask, blow in nitrogen until the oxygen in the system is eliminated, stir for 0.5h, then lower the temperature below 30°C, and add cerium ammonium nitrate to a concentration of 5mmol / L (that is, the content of cerium ammonium nitrate in every L solution of the three-necked bottle is 5mmol) and methyl acrylate to a concentration of 0.5mol / L (that is, the content of methyl acrylate in every L solution of the three-necked bottle is 0.5mol) to carry out graft copolymerization React for 1h, add 2ml of 5% hydroquinone to stop the reaction, filter, wash the filter cake with distilled water, dry at 60°C, wash off the homopolymer with acetone in a Soxhlet extractor, and dry it to obtain the graft copolymer;

[0024] 3) Add 1000ml of 0.5mol / L sodium hydroxide solution to the dried graft copolymer, carry o...

Embodiment 2

[0026] 1) Grinding the soybean dregs to 100 mesh, drying to obtain soybean dregs powder;

[0027] 2) Add 1g of soybean dregs powder and 150ml of 3mol / L silicic acid into the three-necked flask, pass nitrogen gas until the oxygen in the system is eliminated, stir for 1h, then lower the temperature below 30°C, add cerium ammonium nitrate to a concentration of 6mmol / L L (that is, the content of cerium ammonium nitrate in every L solution of the there-necked bottle is 6mmol) and methyl acrylate to a concentration of 0.8mol / L (that is, the content of methyl acrylate in every L solution of the there-necked bottle is 0.8mol) to carry out graft copolymerization reaction 2h, add 2ml of 5% hydroquinone to stop the reaction, filter, wash the filter cake with distilled water, dry at 60°C, wash off the homopolymer with acetone in a Soxhlet extractor, and dry, which is graft copolymerization thing;

[0028] 3) Add 1500ml of 1mol / L sodium hydroxide solution to the dried graft copolymer and ...

Embodiment 3

[0030] 1) Grinding soybean dregs to 80 meshes, drying to obtain soybean dregs powder;

[0031] 2) Add 1g of soybean dregs powder and 120ml of 2.5mol / L silicic acid into the three-necked flask, pass nitrogen gas until the oxygen in the system is eliminated, stir for 0.8h, then lower the temperature below 30°C, and add cerium ammonium nitrate to a concentration of 5.5mmol / L (that is, the content of cerium ammonium nitrate in every L solution of the there-necked bottle is 5.5mmol) and methyl acrylate until the concentration is 0.6mol / L (that is, the content of methyl acrylate in every L solution of the there-necked bottle is 0.6mol) Graft copolymerization reaction 1.5h, add 2ml 5% hydroquinone to stop the reaction, filter, wash the filter cake with distilled water, after drying at 60°C, wash away the homopolymer with acetone in a Soxhlet extractor, dry, That is graft copolymer;

[0032] 3) Add 100ml of 0.8mol / L sodium hydroxide solution to the dried graft copolymer and carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com