High-yield cellulase trichoderma reesei engineering bacteria and preparing method and application thereof

A technology of enzyme Trichoderma reesei and Trichoderma reesei, which is applied in the field of high-yield cellulase Trichoderma reesei engineering bacteria and its preparation, can solve the problems of strong inhibition of carbon metabolism, slow growth, low efficiency, etc., and achieve strong The effect of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

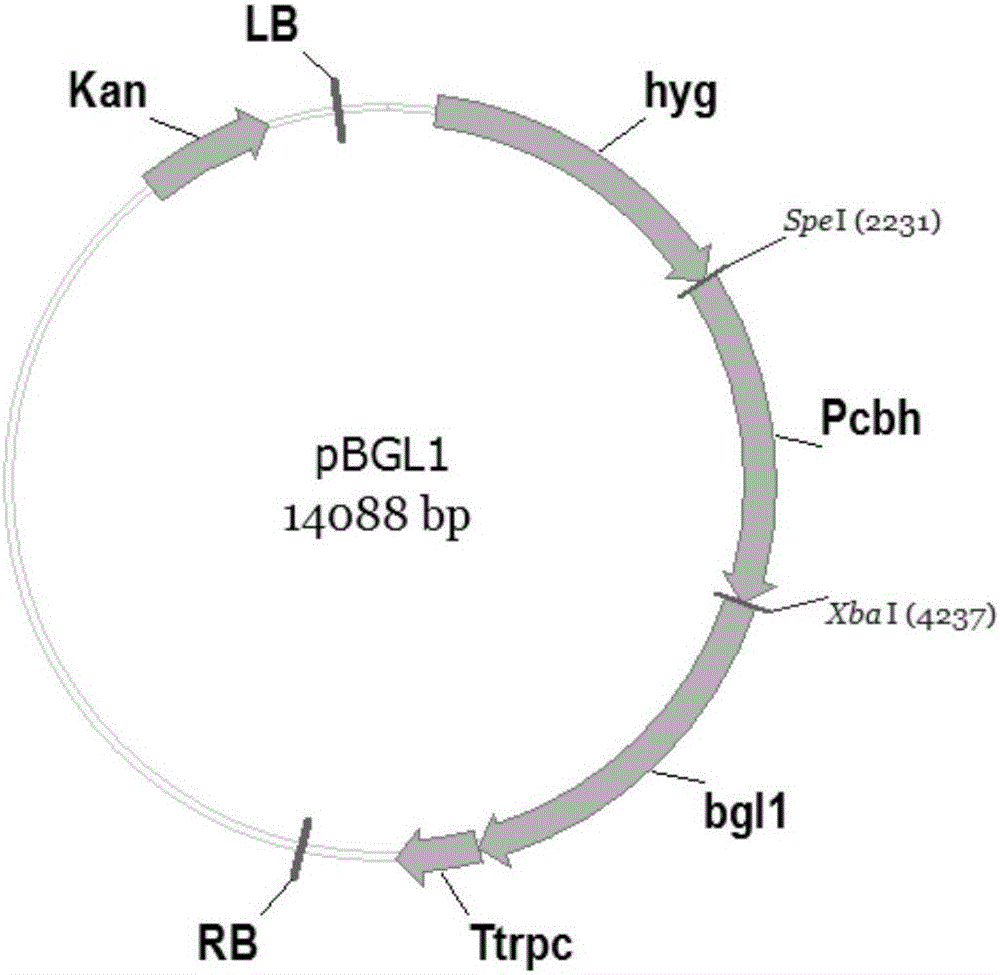

[0059] The construction of the pBGL expression cassette comprises the following steps:

[0060] (1) The design of primers for bgl1 gene amplification is shown in Table 1. Using the cDNA of Trichoderma reesei Rut-C30 as a template, the primers were used to amplify the bgl1 gene. The amplification conditions are pre-denaturation: 95°C, 15s; denaturation: 95°C, 15s; annealing: 66°C, 30s; extension: 72°C, 3min; thorough extension: 72°C, 5min;

[0061] (2) The purified PCR product of the target gene was inserted into the XbaI restriction site of the plasmid pDht / sk by single-digestion homologous recombination to obtain the expression cassette pBGL, see figure 1 ;

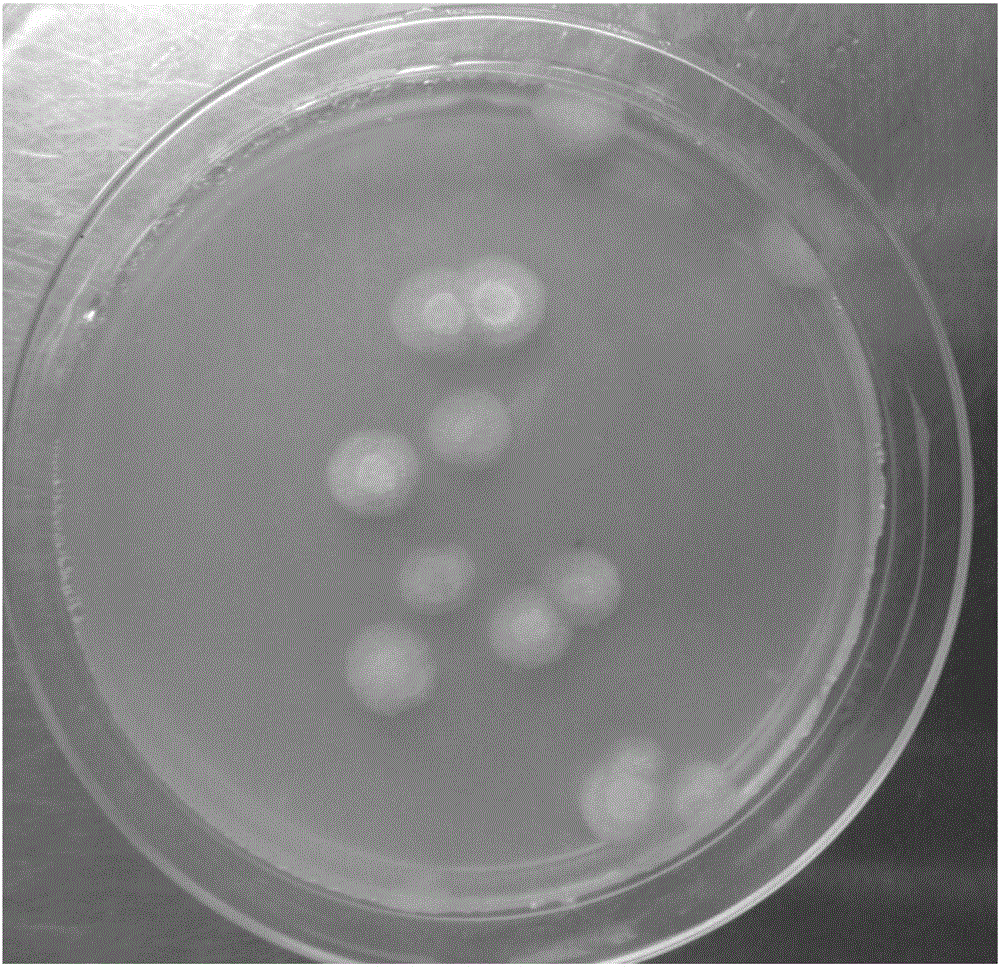

[0062] (3) Adopting the method mediated by Agrobacterium to transfer the expression cassette into Trichoderma reesei spores The specific method is as follows:

[0063] Agrobacterium tumefaciens transformation:

[0064] a. Agrobacterium tumefaciens maintained at -70°C were incubated on ice for 10 minutes;

[0065] b....

Embodiment 2

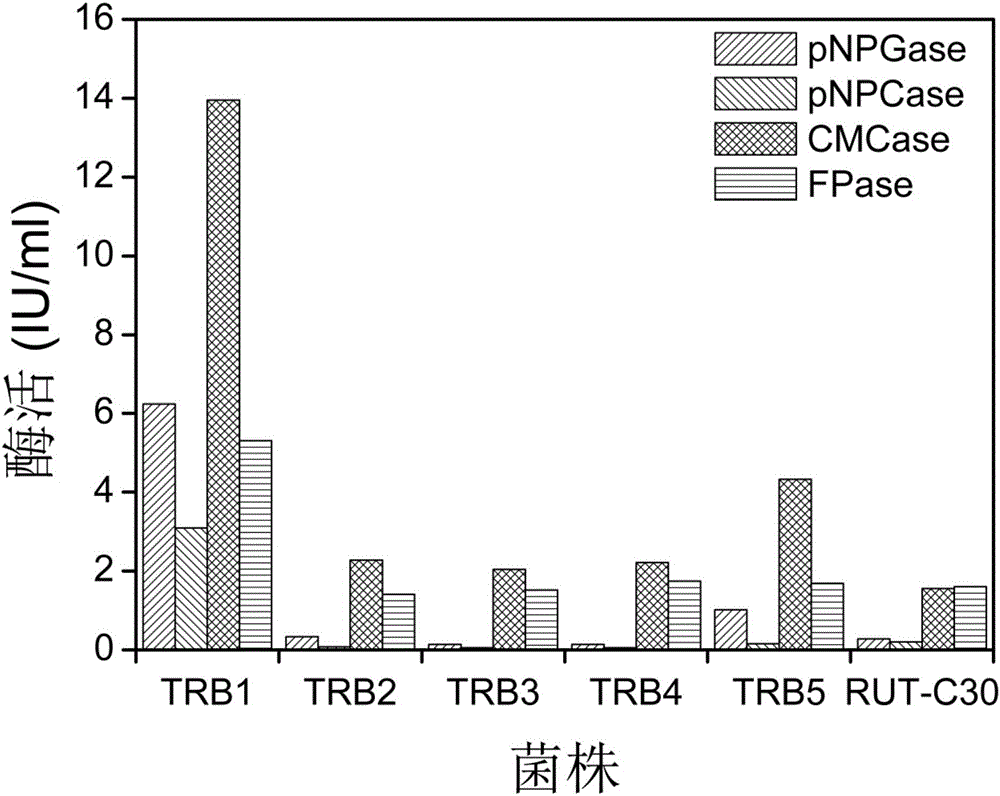

[0074] The supernatants obtained from each strain of Trichoderma reesei cultured in cellulose medium shake flasks for 7 days were centrifuged at 4° C. at 8000 rpm for 15 minutes to collect the supernatants for the determination of cellulase activity. Cellulase activity assay method is as follows:

[0075] (1) Determination of β-glucosidase (pNPGase) enzyme activity: add 20 μl of appropriately diluted enzyme supernatant to 90 μl of 4 mM pNPG (50 mM NaCl, pH 5.0), incubate at 50°C for 10 min, draw 100 μl and add an equal volume of 2 %NaCO3, placed on a microtiter plate to read OD405 (Biochem-Tokyo 1999, 125(4):728-736).

[0076] (2) Determination of exoglucanase (pNPC) enzyme activity: 90μl of 4mM pNPC solution (0.05M NaAc, pH5.0, 1mg / ml 1,5-δ-gluconolactone) was added to 20μl of appropriate dilution factor Enzyme solution, incubate at 50°C for 30 minutes, draw 100 μl and add an equal volume of 2% NaCO3, place in a microtiter plate and read OD405 (Anal Biochem 1984,138(2):481-4...

Embodiment 3

[0080] The supernatants obtained from various strains of Trichoderma reesei cultured in cellulose medium with different concentrations of glucose in shake flasks for 7 days were centrifuged to collect the supernatants for the determination of cellulase activity. The cellulase activity assay method refers to Example 3, and the assay results are shown in FIG. 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com