A Fermented Product of Turbot Fish Skin with Antioxidant Activity

The technology of a fermentation product, turbot, is applied in the field of preparation of natural antioxidant substances, which can solve problems such as waste of resources and environment, and achieve the effects of low cost consumption, good color and luster, and improved consumer acceptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

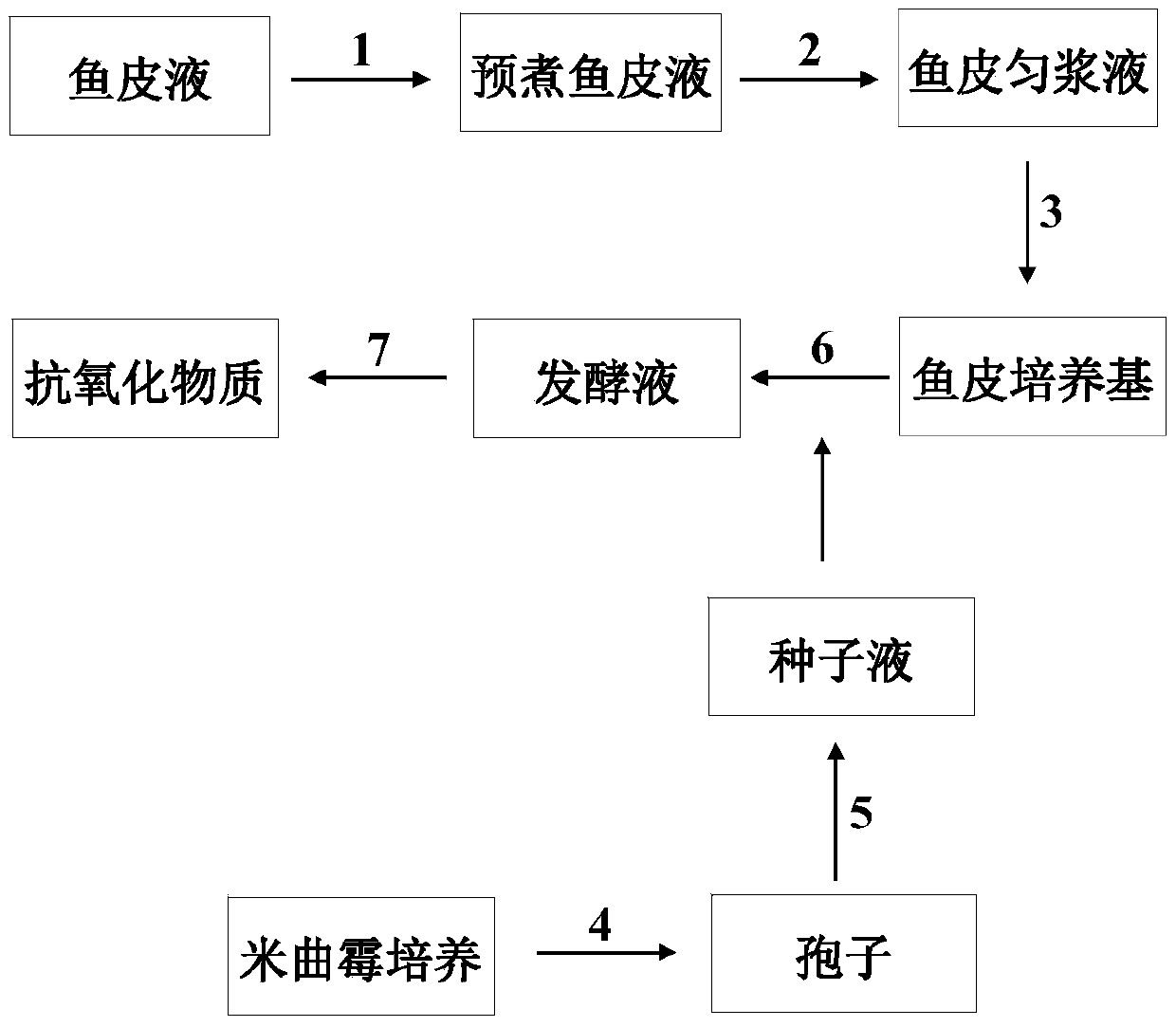

[0022] The antioxidant substance of the present invention mainly uses microorganisms to biodegrade turbot skin, and obtains corresponding antioxidant activity by degrading inactive protein in fish skin into small peptides or amino acid hydrolyzate. The invention selects common food-grade strains and obtains antioxidant active substances by directly fermenting turbot skin, which mainly includes fish skin culture medium preparation, strain cultivation, strain activation, inoculation fermentation, and product separation. Such as figure 1 Shown, the preparation method step of the present invention is as follows:

[0023] 1. Preparation of fish skin culture medium:

[0024] 1. Fish skin precooking conditions: put the fish skin liquid with a material-to-liquid ratio of 1:3 to 3:2 in a boiling water bath and boil for 30 minutes;

[0025] 2. After the pre-boiled fish skin liquid is cooled to room temperature, transfer it to a homogenizer for crushing. The crushing conditions are: 40...

Embodiment 1

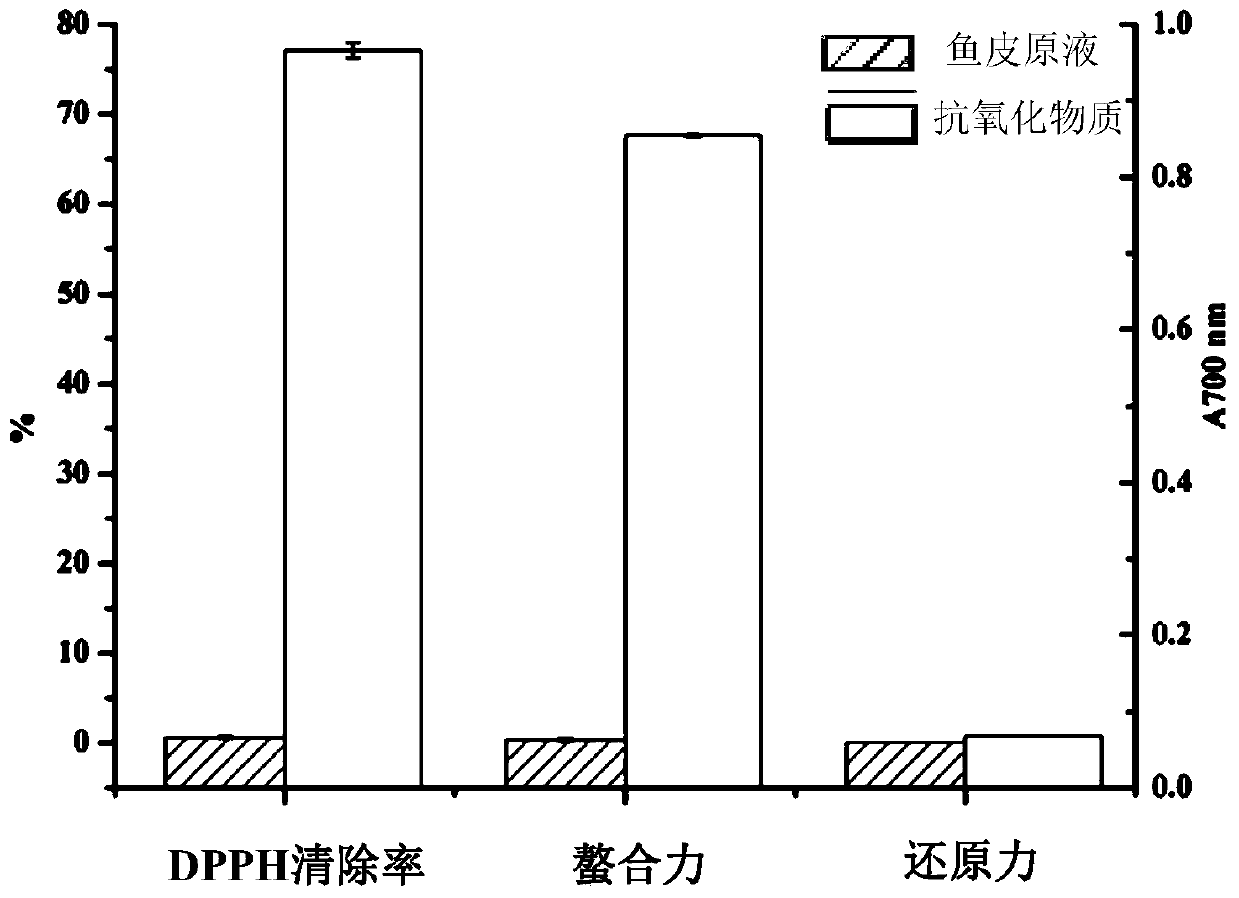

[0033] Embodiment 1: the screening of turbot fish skin fermentation strain

[0034] Lactic acid bacteria were used as the fermentation strains of turbot fish skin, and the activation conditions of the strains were respectively; 37°C, anaerobic static culture, and the culture time was 2 days. The activated strains were inserted into the medium of turbot fish skin, the inoculum amount was 10%, the ratio of solid to liquid was 40%, and the fermentation time was 5 days. The fermentation broth was filtered through four layers of gauze, the filtrate was centrifuged, and the fermentation product was freeze-dried. The measurement results showed that the hydrolysis degree of the product was 5.19%, and the DPPH clearance rate was 10.83%.

Embodiment 2

[0035] Embodiment 2: the screening of turbot fish skin fermentation strain

[0036] Yeast is used as the fermentation strain of turbot fish skin, and the activation conditions of the strain are respectively; 30°C, 180rmp, and the culture time is 2 days. The activated strains were inserted into the medium of turbot fish skin, the inoculum amount was 10%, the ratio of solid to liquid was 40%, and the fermentation time was 5 days. The fermentation broth was filtered through four layers of gauze, the filtrate was centrifuged, and the fermentation product was freeze-dried. The measurement results showed that the hydrolysis degree was 3.44%, and the DPPH clearance rate was 38.89%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com