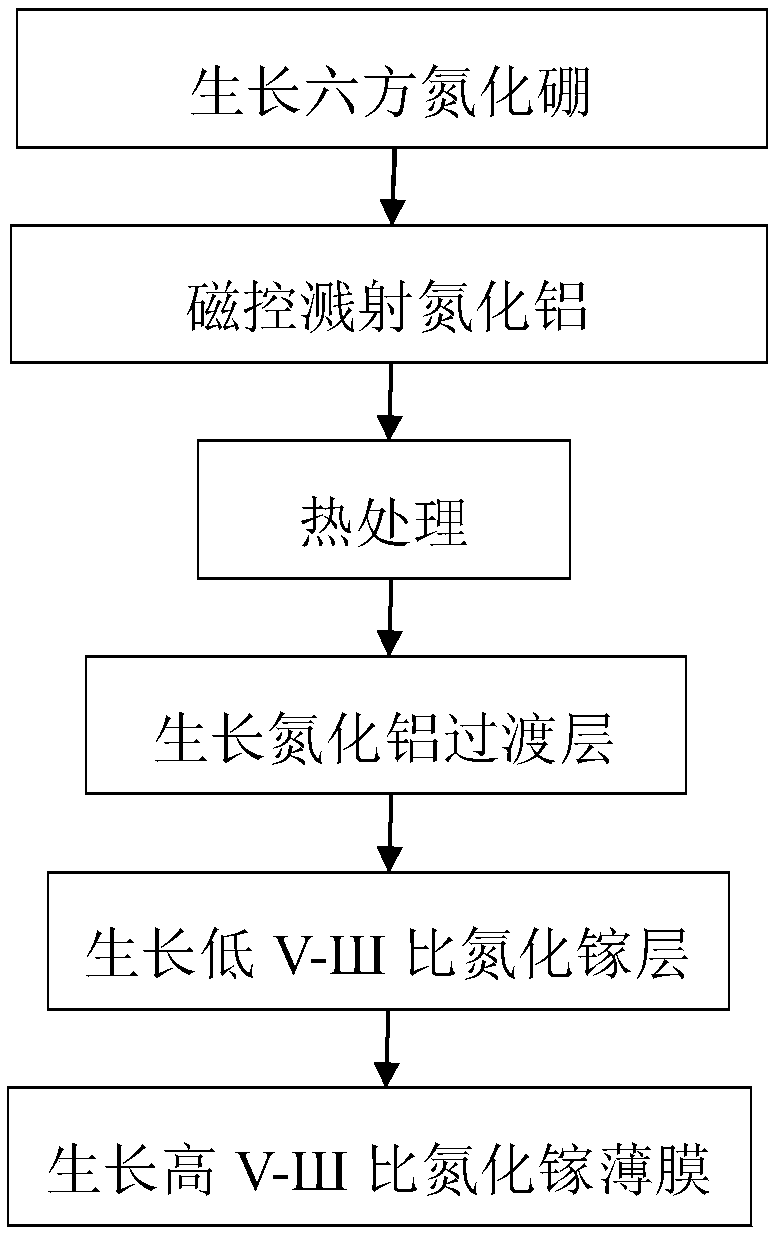

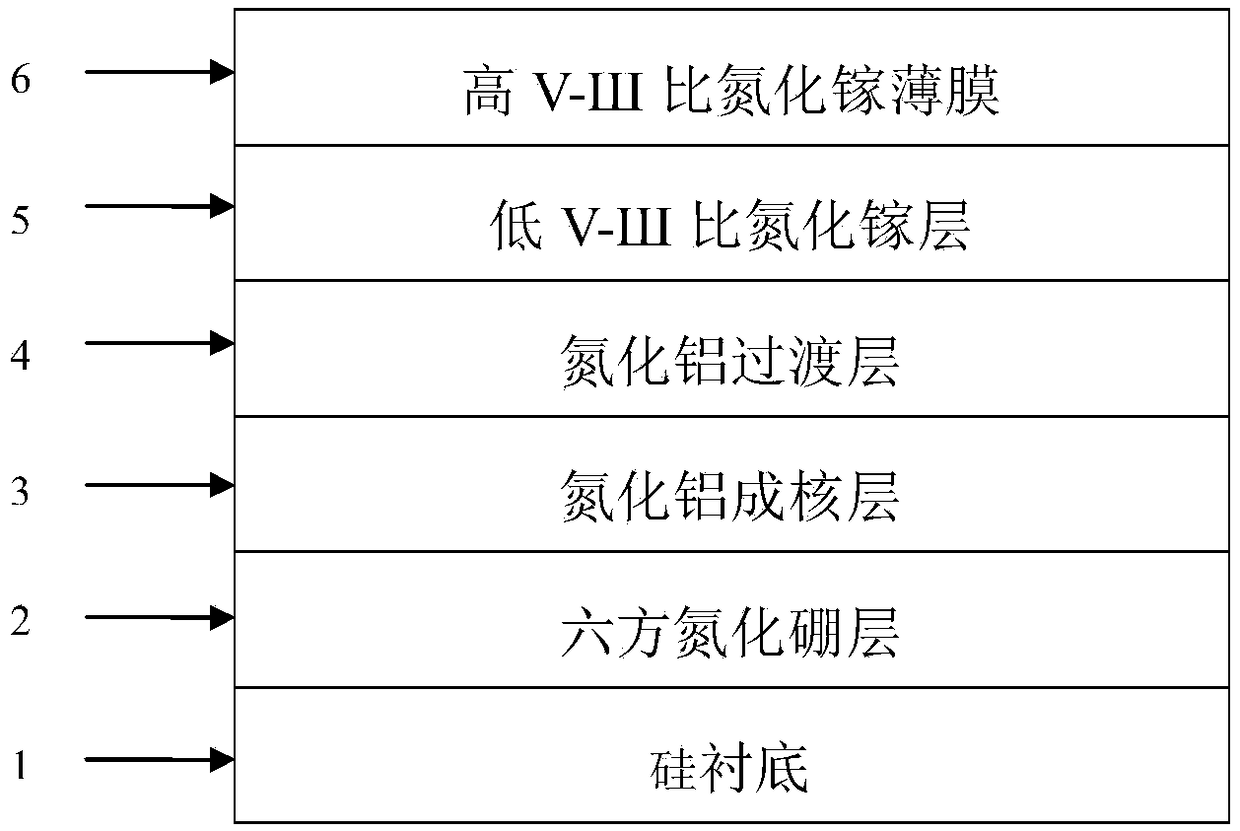

GaN Growth Method Based on Hexagonal Boron Nitride and Magnetron Sputtering AlN

A technology of hexagonal boron nitride and magnetron sputtering, which is applied in the field of electronics, can solve the problems of complex process, poor quality of epitaxial gallium nitride, and high background carrier concentration, so as to achieve improved material quality, excellent manufacturing performance, and good heat dissipation. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: Ga-surface gallium nitride film based on hexagonal boron nitride and magnetron sputtering aluminum nitride.

[0053] Step 1. Growing a hexagonal boron nitride transition layer.

[0054] First dry the pretreated silicon substrate, put it into the microwave plasma chemical vapor deposition MPCVD reaction chamber, then evacuate the microwave plasma chemical vapor deposition MPCVD reaction chamber, and feed a small amount of hydrogen gas with a flow rate of 50 sccm. Turn on the microwave generator in the microwave plasma chemical vapor deposition MPCVD reaction chamber, start the excitation to generate plasma, and clean the silicon wafer for 10 minutes. Then feed the nitrogen gas with a purity of 99.9% and a flow rate of 150 sccm, the helium gas with a purity of 99.9% and a flow rate of 150 sccm, and the boron fluoride gas with a flow rate of 50 sccm. The boron fluoride gas is composed of 90% nitrogen and 10% boron fluoride . After raising the working pressu...

Embodiment 2

[0066] Embodiment 2: N-face gallium nitride film based on hexagonal boron nitride and magnetron sputtering aluminum nitride.

[0067] Step A. Growing a hexagonal boron nitride transition layer.

[0068] First dry the pretreated silicon wafer substrate, put it into the microwave plasma chemical vapor deposition MPCVD reaction chamber, then vacuum the microwave plasma chemical vapor deposition MPCVD reaction chamber, and feed a small amount of hydrogen gas, the flow rate of hydrogen gas is 50sccm . Turn on the microwave generator in the microwave plasma chemical vapor deposition MPCVD reaction chamber, start the excitation to generate plasma, and clean the silicon wafer for 10 minutes. Then feed the nitrogen gas with a purity of 99.9% and a flow rate of 150 sccm, the helium gas with a purity of 99.9% and a flow rate of 150 sccm, and the boron fluoride gas with a flow rate of 50 sccm. The boron fluoride gas is composed of 90% nitrogen and 10% boron fluoride . After raising the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com