Nickel stripping solution and preparation method and application thereof

A nickel-removing solution and nickel-removing technology, applied in the field of chemical nickel-removing, can solve the problems of human body harm, pollute the working environment, and increase the nitrogen content of the solution, and achieve the effects of prolonging the service life, reducing the nitrogen content and high cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

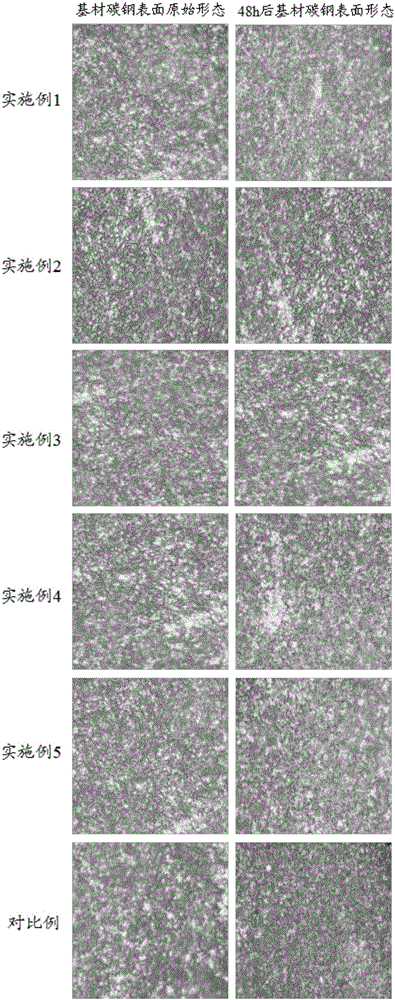

Image

Examples

Embodiment 1

[0035]

[0036] According to the above formula, first add one-third of the volume of water to the nickel-containing tank, add the required amount of sulfuric acid and stir; the required amount of citric acid is dissolved in pure water and added to the tank while stirring; finally add the required amount of Stir isopropanol, p-hydroxybenzenesulfonic acid and hydrogen peroxide evenly and add water to the operating liquid level to prepare nickel stripping solution.

Embodiment 2

[0038]

[0039] According to the above formula, first add one-third of the volume of water to the nickel-containing tank, add the required amount of sulfuric acid and stir; the required amount of 1,2-diaminocyclohexanetetraacetic acid is dissolved in pure water and added to the tank while stirring middle; finally add the required amount of ethylene glycol, p-hydroxybenzenesulfonic acid and hydrogen peroxide in turn, stir evenly and add water to the operating liquid level to prepare the nickel stripping solution.

Embodiment 3

[0041]

[0042] According to the above formula, first add one-third of the volume of water to the nickel-containing tank, add the required amount of sulfuric acid and stir; the required amount of 1,2-diaminocyclohexanetetraacetic acid is dissolved in pure water and added to the tank while stirring middle; finally add the required amount of ethylene glycol methyl ether, p-hydroxybenzenesulfonic acid and hydrogen peroxide in turn, stir evenly and add water to the operating liquid level to prepare the nickel stripping solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com