Xyloglucan film

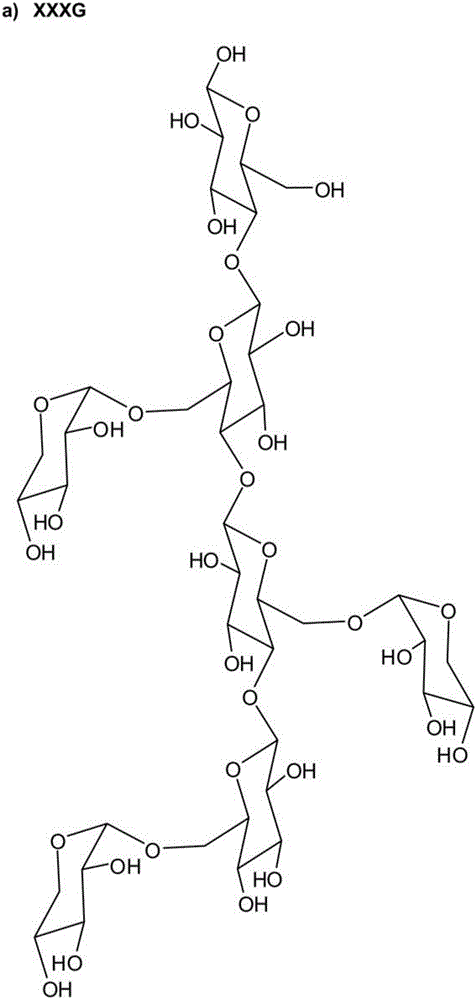

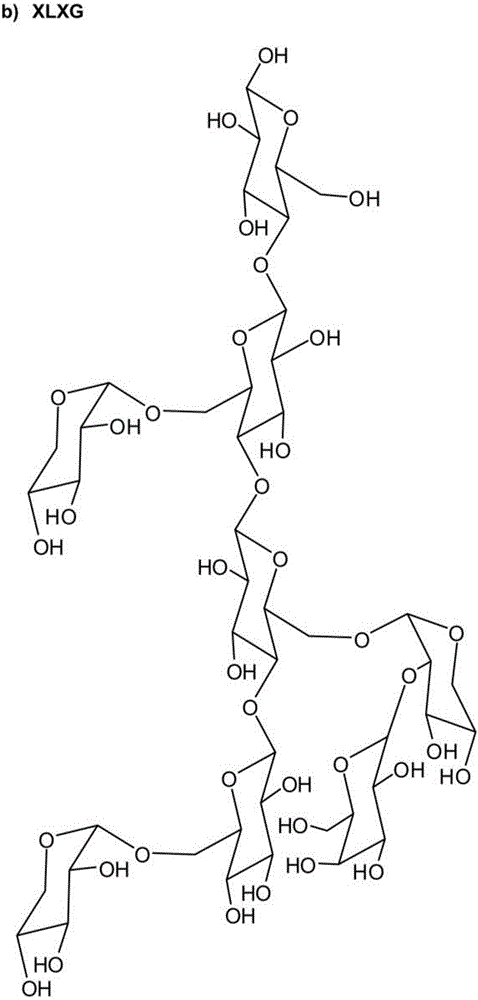

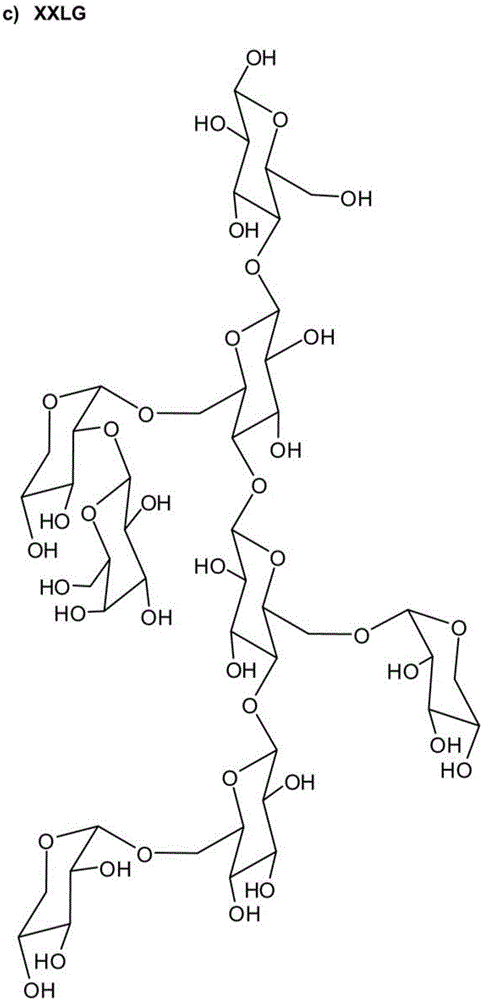

一种木葡聚糖、半乳糖的技术,应用在木葡聚糖膜领域,能够解决水溶性丧失等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Another advantage of using XG comprising up to 11 mol % of galactose residues in the preparation of the membranes of the invention is that XG comprising up to 11 mol % of galactose residues can be redissolved in water by simple mechanical homogenization , such as with a high shear mixer or in a microfluidizer; and optionally in combination with sonication. Xyloglucans comprising up to 11 mole % of galactose residues are also soluble in organic solvents, ionic solvents or ionic liquids, or mixtures of these solvents with each other or with water, such as dimethylsulfoxide , N-methylmorpholine N-oxide, dimethylformamide, dimethylacetamide, dimethylacetamide / LiCl, 1,3-dimethyl-3,4,5,6-tetrahydro -2(1H)-pyrimidinone, NaOH (aq), LiOH / urea, NaOH / urea, ammonium hydroxide.

[0037] Another advantage is the increase in elastic modulus, eg at 50% RH from 4.6 GPa for unmodified xyloglucan derived from tamarind to 5.4 GPa for XG containing up to 11 mol% galactose residues. Also f...

Embodiment

[0065] Material

[0066] Enzyme modification of xyloglucan. Industrially available tamarind seed xyloglucan (weight average molecular weight, 1.5-2.0 MDa, Innovassynth technologies Ltd., India) was separated by centrifugation (4000 rpm for 45 minutes) of a 0.5 wt % dilute solution purified and lyophilized to obtain pure xyloglucan. 2 g of lyophilized xyloglucan were dissolved in 80 ml of 50 mM sodium acetate buffer (pH=4.5). For partial removal of galactose side groups, 50 mg β-galactosidase (derived from Aspergillus oryzae, Sigma Aldrich) dissolved in 5 ml MilliQ water was added to the XG solution. The reaction mixture was kept at 30°C for different treatment times - 24h, 51h and 64h. After the specified time the reaction was terminated by heating at 90°C for 30 minutes to inactivate the enzyme. Modified XG (mXG) was purified by precipitation and washing in ethanol, and dried in a vacuum oven at 50 °C for 24 h. The modified XG samples were insoluble or slightly soluble ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com