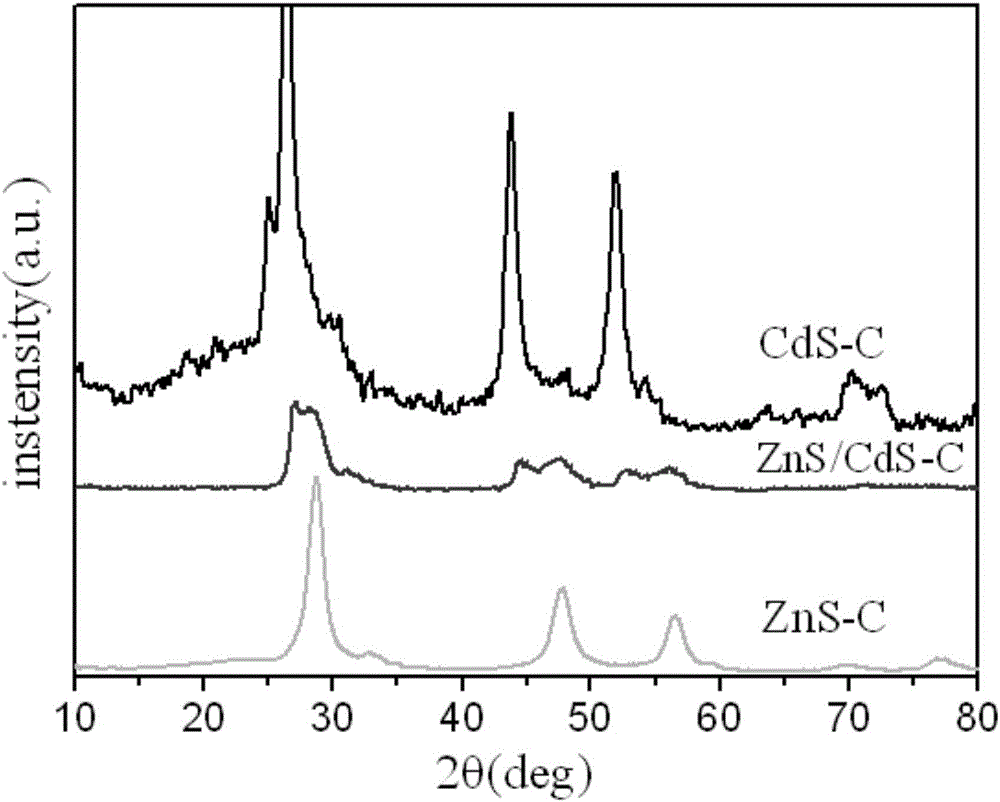

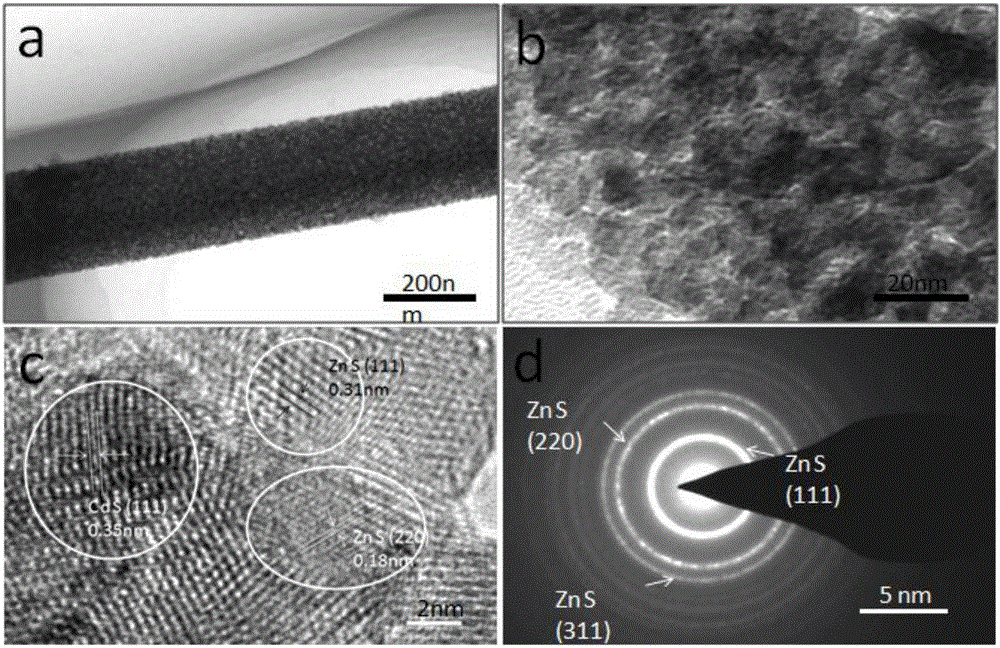

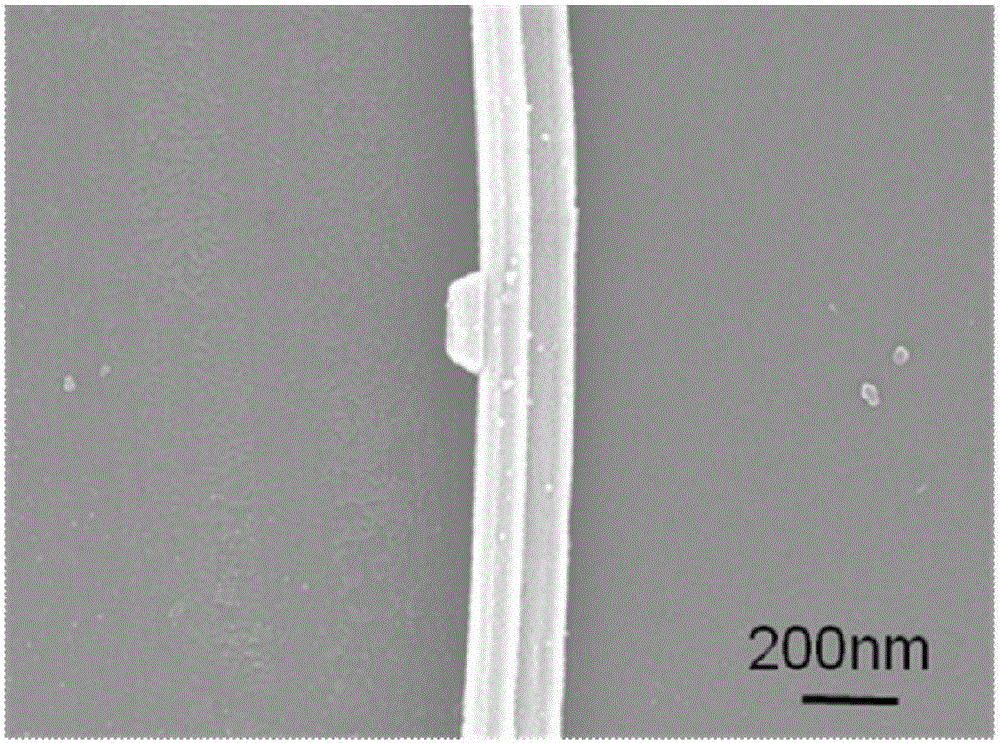

One-dimensional ZnS (zinc sulfide)/CdS-C nanocomposite material and preparation method thereof

A nanocomposite material, cds-c technology, applied in the field of one-dimensional ZnS/CdS-C nanocomposite system nanomaterials and its preparation, can solve the problems of large-scale use of ZnS photocatalyst, low utilization rate of visible light, electron and space Holes are easy to recombine and other problems, to achieve the effect of improving photocatalytic efficiency, high stability and adsorption capacity, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Weigh 17.85g Zn(NO3 ) 2 ·6H 2 0 and 17.292g of sodium benzoate were dissolved in 150mL deionized water respectively at room temperature to prepare a salt solution, and the prepared two kinds of salt solutions were poured into a four-necked flask, and started to rotate at a constant speed with an electric stirrer to make the salt solution mix evenly ;

[0029] 2) Weigh 2g NaOH and dissolve it in 100mL deionized water to prepare lye, slowly add lye dropwise to the mixed salt solution, and white precipitates will appear in the solution, adjust the pH of the solution to 5.7, raise the temperature to 80°C, and React at this temperature for 24 hours. After the reaction, the precipitate is taken out, centrifuged, washed 4 times with deionized water, and the product is dried at 50°C for 6 hours to obtain a one-dimensional benzoate-intercalated layered zinc hydroxide nano Fibrous precursors.

[0030] 3) Place the benzoate intercalated layered zinc hydroxide nanofiber precu...

Embodiment 2

[0040] 1) Weigh 17.85g Zn(NO 3 ) 2 ·6H 2 0 and 17.292g of sodium benzoate were dissolved in 150mL deionized water respectively at room temperature to prepare a salt solution, and the prepared two kinds of salt solutions were poured into a four-necked flask, and started to rotate at a constant speed with an electric stirrer to make the salt solution mix evenly ;

[0041] 2) Weigh 2g NaOH and dissolve it in 100mL deionized water to prepare lye, slowly add lye dropwise to the mixed salt solution, and white precipitates will appear in the solution, adjust the pH of the solution to 5.7, raise the temperature to 80°C, and React at this temperature for 24 hours. After the reaction, the precipitate is taken out, centrifuged, washed 4 times with deionized water, and the product is dried at 50°C for 6 hours to obtain a one-dimensional benzoate-intercalated layered zinc hydroxide nano Fibrous precursors.

[0042] 3) Place the benzoate intercalated layered zinc hydroxide nanofiber pre...

Embodiment 3

[0047] 1) Weigh 17.85g Zn(NO 3 ) 2 ·6H 2 0 and 17.292g of sodium benzoate were dissolved in 150mL deionized water respectively at room temperature to prepare a salt solution, and the prepared two kinds of salt solutions were poured into a four-necked flask, and started to rotate at a constant speed with an electric stirrer to make the salt solution mix evenly ;

[0048] 2) Weigh 2g NaOH and dissolve it in 100mL deionized water to prepare lye, slowly add lye dropwise to the mixed salt solution, and white precipitates will appear in the solution, adjust the pH of the solution to 5.7, raise the temperature to 80°C, and React at this temperature for 24 hours. After the reaction, the precipitate is taken out, centrifuged, washed 4 times with deionized water, and the product is dried at 50°C for 6 hours to obtain a one-dimensional benzoate-intercalated layered zinc hydroxide nano Fibrous precursors.

[0049] 3) Place the benzoate intercalated layered zinc hydroxide nanofiber pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com