Resin crosslinking polyvinyl alcohol type aerogel and preparation method and application of resin crosslinking polyvinyl alcohol type aerogel

A technology of cross-linked polyvinyl alcohol and polyvinyl alcohol, which is applied in the field of airgel materials and its preparation, can solve problems such as poor mechanical properties, low airgel strength, and water absorption of products, and achieve improved flame retardancy, Improve mechanical properties and avoid hard-to-form effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

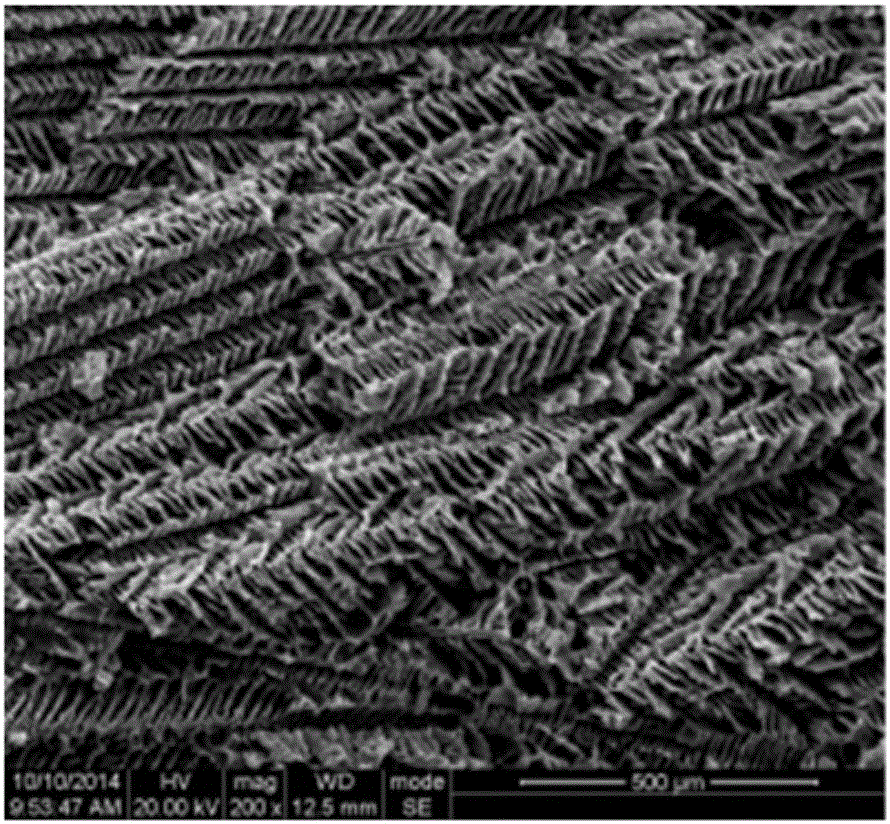

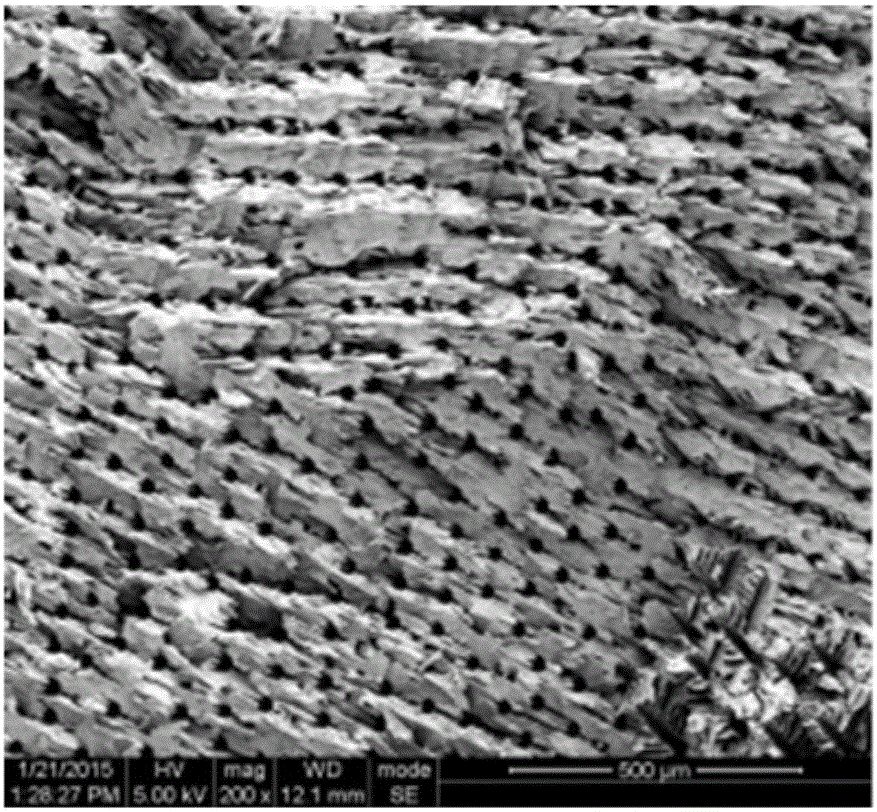

[0038] The melamine and formaldehyde were first stirred and mixed according to the molar ratio of 1:3 and the pH of the system was adjusted to 8.5, and then reacted at 80°C for 30 minutes to obtain a melamine-formaldehyde resin precursor solution; The polyvinyl alcohol solution with a concentration of 1% is mixed evenly according to the hydroxyl molar ratio of 1:0.2, then the pH of the system is adjusted to 1, poured into the mold, and then frozen at -5℃ to solid, and then at -80℃ Dry under vacuum to prepare polyvinyl alcohol aerogel mixed with resin precursor; cross-link and solidify the prepared aerogel at 60° C. for 60 hours.

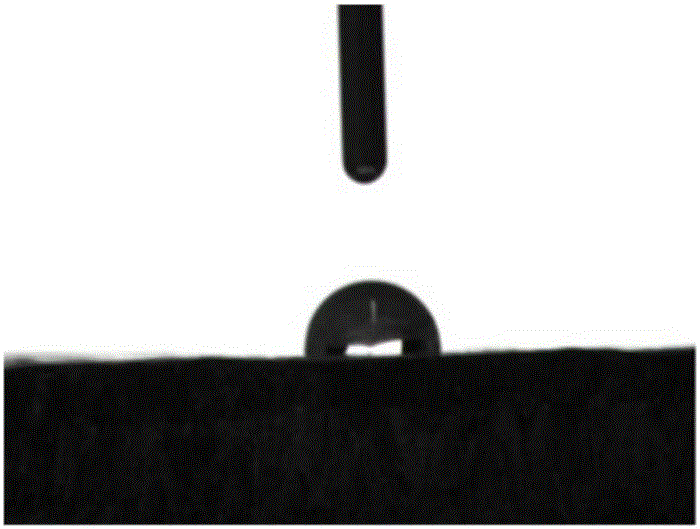

[0039] The density, oxygen index, peak heat release rate, compression modulus, water contact angle, dissolution in water at 90°C for 12 hours and shrinkage after vacuum drying of the obtained aerogel material are shown in the attached table.

Embodiment 2

[0041] First, stir and mix melamine and formaldehyde in a molar ratio of 1:3 and adjust the pH of the system to 8.5, then react at 80°C for 40 minutes to prepare a melamine-formaldehyde resin precursor solution; the melamine-formaldehyde resin precursor solution and mass percentage The 2% polyvinyl alcohol solution is mixed evenly according to the hydroxyl molar ratio of 1:0.5, then the pH of the system is adjusted to 4, poured into the mold, and then frozen at -50℃ to solid, and then at -50℃ Dry under vacuum to obtain polyvinyl alcohol aerogel mixed with resin precursor; cross-link and solidify the obtained aerogel at 80°C for 48 hours.

[0042] The density, oxygen index, peak heat release rate, compression modulus, water contact angle, dissolution in water at 90°C for 12 hours and shrinkage after vacuum drying of the obtained aerogel material are shown in the attached table.

Embodiment 3

[0044] First, stir and mix melamine and formaldehyde in a molar ratio of 1:3 and adjust the pH of the system to 8.5, then react at 80°C for 50 minutes to prepare a melamine-formaldehyde resin precursor solution; the melamine-formaldehyde resin precursor solution and mass percentage The polyvinyl alcohol solution with a concentration of 5% is mixed uniformly according to the molar ratio of hydroxyl group at 1:1, then the pH of the system is adjusted to 5, poured into the mold, and then frozen at -80℃ to solid, and then at -20℃ Dry under vacuum to prepare polyvinyl alcohol aerogel mixed with resin precursor; cross-link and solidify the prepared aerogel at 90°C for 36 hours.

[0045] The density, oxygen index, peak heat release rate, compression modulus, water contact angle, dissolution in water at 90℃ for 12 hours and shrinkage after vacuum drying of the obtained aerogel materials are shown in the attached table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com