Expediting setting polyurethane pouring sealant material and preparing method thereof

A potting glue and polyurethane technology, applied in the field of sealants, can solve the problems of long curing time, unenvironmental protection, and opaque potting glue, and achieve the effect of shortening curing time, improving production efficiency and fast curing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 A polyurethane potting material

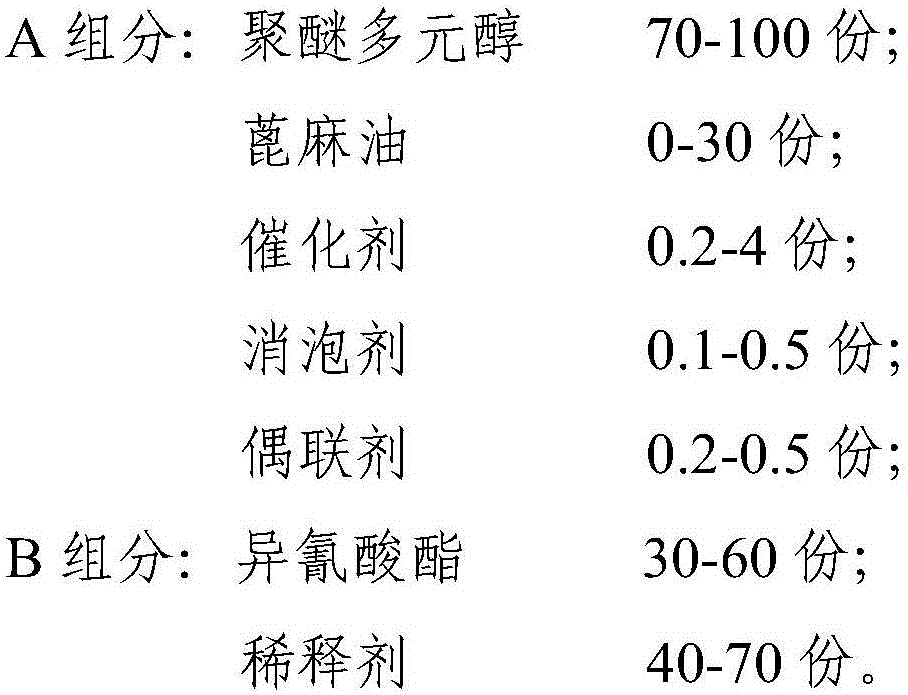

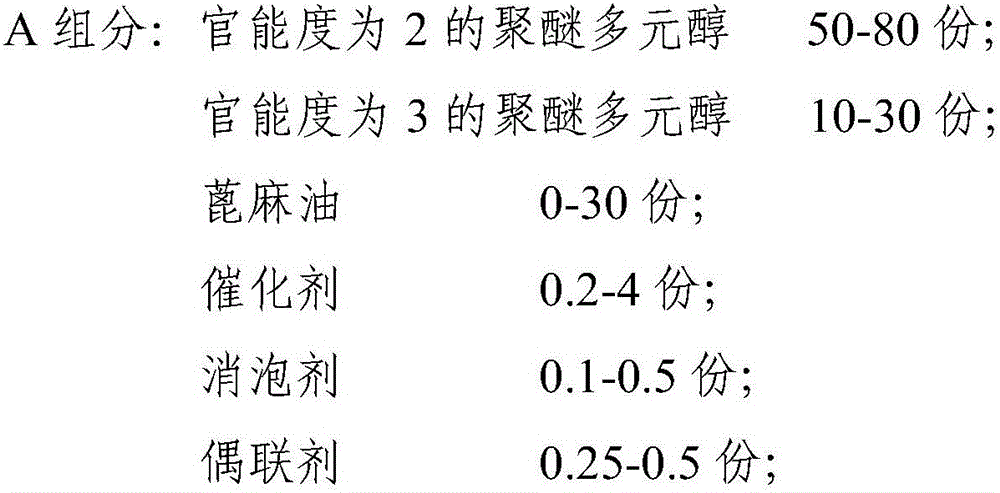

[0032] This embodiment provides a polyurethane potting adhesive material, which contains the following composition in parts by mass:

[0033] Component A: 80 parts of polyether polyol with a functionality of 2 after dehydration, 20 parts of polyether polyol with a functionality of 3, 0.2 part of organic bismuth catalyst 1610, 0.1 part of defoamer BYK 054, coupling agent 0.2 parts of KH-550, stir well, and keep in a sealed seal.

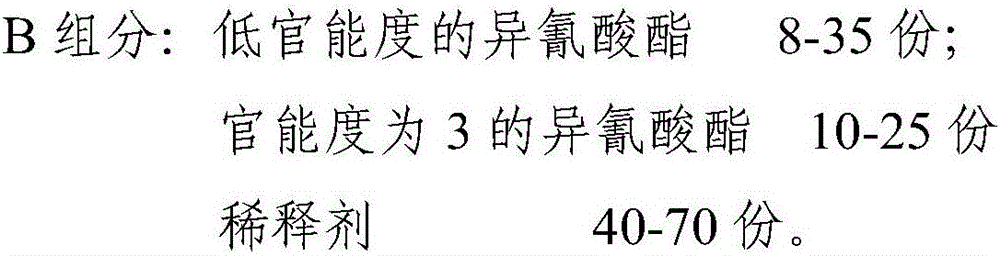

[0034] Component B: 8 parts of liquefied MDI with a functionality of 2, 22 parts of an isocyanate oligomer with a functionality of 3, and 70 parts of dehydrated dioctyl phthalate (DOP), stir well, and keep sealed.

Embodiment 2

[0035] Example 2 A polyurethane potting material

[0036] This embodiment provides a polyurethane potting adhesive material, which contains the following composition in parts by mass:

[0037] Component A: 70 parts of 2-functional polyether polyol after dehydration, 20 parts of 3-functional polyether polyol, 10 parts of castor oil, 0.4 part of organic bismuth catalyst, 0.2 part of organic zinc catalyst 1910, defoaming 0.2 parts of agent BYK 067A, 0.25 parts of coupling agent KH-560, stir well, and keep sealed.

[0038] Component B: 10 parts of MDI-50 (functionality 2), 10 parts of MDI prepolymer (functionality between 2-3), 20 parts of isocyanate oligomers (functionality 3), dehydrated phthalate 60 parts of dioctyl diformate, stir evenly, and keep sealed.

Embodiment 3

[0039] Example 3 A polyurethane potting material

[0040] This embodiment provides a polyurethane potting adhesive material, which contains the following composition in parts by mass:

[0041] Component A: 60 parts of 2-functional polyether polyol after dehydration, 10 parts of 3-functional polyether polyol, 30 parts of castor oil, 2 parts of organic zinc catalyst, 0.5 part of defoamer 141, coupling agent KH550 0.25 parts, stir well, and keep sealed.

[0042] B component: polymeric MDI (functionality between 2-3) 5 parts, MDI prepolymer (functionality between 2-3) 22 parts, isocyanate oligomer 10 parts (functionality is 3), 63 parts of dehydrated dioctyl phthalate, stir evenly, and keep sealed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com