Porous foamy copper material and production method thereof

A technology of porous foam and bronze powder, applied in the field of foam materials, can solve the problems of high cost, narrow range of material selection, complicated process, etc., and achieve high platform stress, high porosity, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

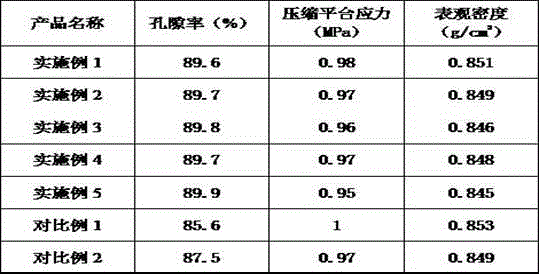

Examples

Embodiment 1

[0017] A porous copper foam material, which is prepared from the following components in parts by weight: 15 parts of polyurethane sponge, 5 parts of bronze powder, 0.2 part of sodium dodecylbenzenesulfonate, 0.5 part of phosphatidylcholine, p-hydroxybenzoic acid 0.1 part of methyl ester, 0.1 part of sodium diacetate, 0.5 part of polyvinyl alcohol, 0.2 part of polyvinyl formal, 0.1 part of glyceryl tristearate, 1 part of sodium hydroxide, 0.1 part of rosin, 0.2 part of methyl cellulose , 2 parts of ethanol, 0.3 parts of ammonia water, and 40 parts of water.

[0018] The preparation method of the above-mentioned porous copper foam material is as follows: (1) Mix and soak polyurethane sponge, sodium hydroxide and 25 parts of water for 1 hour; (2) Mix all the remaining components and stir for 3 minutes with a mixer at a speed of 80r / min Form a slurry and let it stand at room temperature for 23 hours; (3) Put the sponge into the slurry and impregnate it repeatedly 3 times, and dry...

Embodiment 2

[0020] A porous copper foam material, prepared from the following components in parts by weight: 17 parts of polyurethane sponge, 8 parts of bronze powder, 0.3 part of sodium dodecylbenzenesulfonate, 0.75 part of phosphatidylcholine, p-hydroxybenzoic acid 0.15 parts of methyl ester, 0.2 parts of sodium diacetate, 0.75 parts of polyvinyl alcohol, 0.35 parts of polyvinyl formal, 0.15 parts of glyceryl tristearate, 1.5 parts of sodium hydroxide, 0.2 parts of rosin, 0.3 parts of methyl cellulose , 3 parts of ethanol, 0.5 parts of ammonia water, and 60 parts of water.

[0021] The preparation method of the above-mentioned porous copper foam material is as follows: (1) Mix and soak polyurethane sponge, sodium hydroxide and 32 parts of water for 1.5 hours; (2) Mix all the remaining components and stir for 4 minutes with a mixer at a speed of 90r / min Form a slurry and let it stand at room temperature for 24 hours; (3) Put the sponge into the slurry and impregnate it repeatedly 4 times...

Embodiment 3

[0023] A porous copper foam material, prepared from the following components in parts by weight: 20 parts of polyurethane sponge, 10 parts of bronze powder, 0.4 part of sodium dodecylbenzenesulfonate, 1 part of phosphatidylcholine, p-hydroxybenzoic acid 0.2 parts of methyl ester, 0.3 parts of sodium diacetate, 1 part of polyvinyl alcohol, 0.5 parts of polyvinyl formal, 0.2 parts of glyceryl tristearate, 2 parts of sodium hydroxide, 0.3 parts of rosin, 0.4 parts of methyl cellulose , 4 parts of ethanol, 0.8 parts of ammonia water, and 80 parts of water.

[0024] The preparation method of the above-mentioned porous copper foam material is as follows: (1) mix and soak polyurethane sponge, sodium hydroxide and 40 parts of water for 2 hours; (2) mix all the remaining components, and stir for 5 minutes with a mixer at a speed of 100r / min Form a slurry and let it stand at room temperature for 25 hours; (3) Put the sponge into the slurry and impregnate it repeatedly 5 times, and dry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com