Planting blanket used for original soil improvement of muddy coastal saline-alkali land

A technology for saline-alkali land and planting blanket, which is applied in the fields of planting substrate, soil protection, application, etc., can solve the problems of slow desalination and alkali washing process, surface soil returning to salt and alkali, poor soil ventilation effect, etc., to achieve good water absorption performance, avoid Plant rotten roots, the effect of ensuring the improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

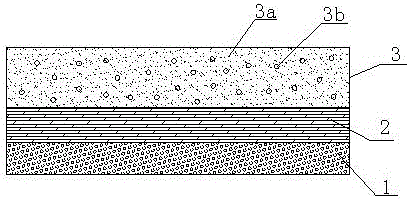

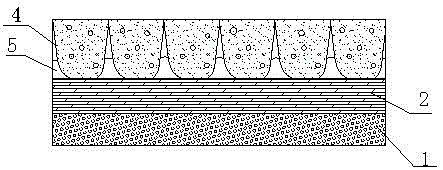

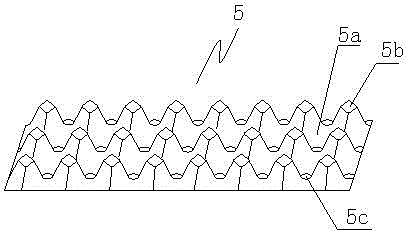

[0038] Such as figure 1As shown, a planting blanket used for soil improvement on muddy coastal saline-alkali lands includes a salt barrier layer 1, a water storage layer 2, and a planting layer 3 from bottom to top. The planting layer 3 includes a planting matrix 3a and is dispersed in the planting matrix plant seeds 3b, the planting matrix 3a includes the following components in parts by weight: 20 parts of grass carbon, 30 parts of decomposed cow dung, 12 parts of decomposed plant straw, 10 parts of decomposed wood chips, 10 parts of wheat bran, 7 parts of fly ash 15 parts of mountain sand, 5 parts of phosphorus rot fertilizer, 5 parts of nitrogen rot fertilizer, 10 parts of desulfurization slag, 8 parts of decomposed rabbit manure, 8 parts of zeolite powder, 20 parts of sucrose bagasse, and 15 parts of decomposed mushroom bag material. The salt barrier material of the salt barrier layer 1 is rice bran. The water storage layer 2 is a layered structure formed by weaving plan...

Embodiment 2

[0040] Such as figure 1 As shown, a planting blanket used for soil improvement on muddy coastal saline-alkali lands includes a salt barrier layer 1, a water storage layer 2, and a planting layer 3 from bottom to top. The planting layer 3 includes a planting matrix 3a and is dispersed in the planting matrix plant seeds 3b, the planting matrix 3a includes the following components in parts by weight: 23 parts of grass carbon, 40 parts of decomposed cow dung, 20 parts of decomposed plant straw, 14 parts of decomposed wood chips, 13 parts of wheat bran, and 8 parts of fly ash 18 parts of mountain sand, 6 parts of phosphorus rot fertilizer, 6 parts of nitrogen rot fertilizer, 15 parts of desulfurization residue, 9 parts of decomposed rabbit manure, 8 parts of zeolite powder, 25 parts of corn sugar residue, and 18 parts of decomposed mushroom bag material. The salt barrier material of the salt barrier layer 1 is a mixture of zeolite and ceramsite. The water storage layer 2 is a poly...

Embodiment 3

[0042] Such as figure 1 As shown, a planting blanket used for soil improvement on muddy coastal saline-alkali lands includes a salt barrier layer 1, a water storage layer 2, and a planting layer 3 from bottom to top. The planting layer 3 includes a planting matrix 3a and is dispersed in the planting matrix plant seeds 3b, the planting matrix 3a includes the following components in parts by weight: 30 parts of grass carbon, 60 parts of decomposed cow dung, 36 parts of decomposed plant straw, 20 parts of decomposed wood chips, 20 parts of wheat bran, 11 parts of fly ash 25 parts of mountain sand, 7 parts of phosphorus rot fertilizer, 7 parts of nitrogen rot fertilizer, 20 parts of desulfurization residue, 10 parts of decomposed rabbit manure, 10 parts of zeolite powder, 30 parts of caramel residue, and 20 parts of decomposed mushroom bag material. The salt barrier material of the salt barrier layer 1 is a mixture of ceramsite, vermiculite or rice bran. The water storage layer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com