Preparation method of solid-liquid bidirectional acidified glycolysis feed

A feed and fermentation technology, applied in the field of enzyme preparations, microorganisms, and feed, can solve the problems of complex process, large investment in fermentation equipment, and expensive raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

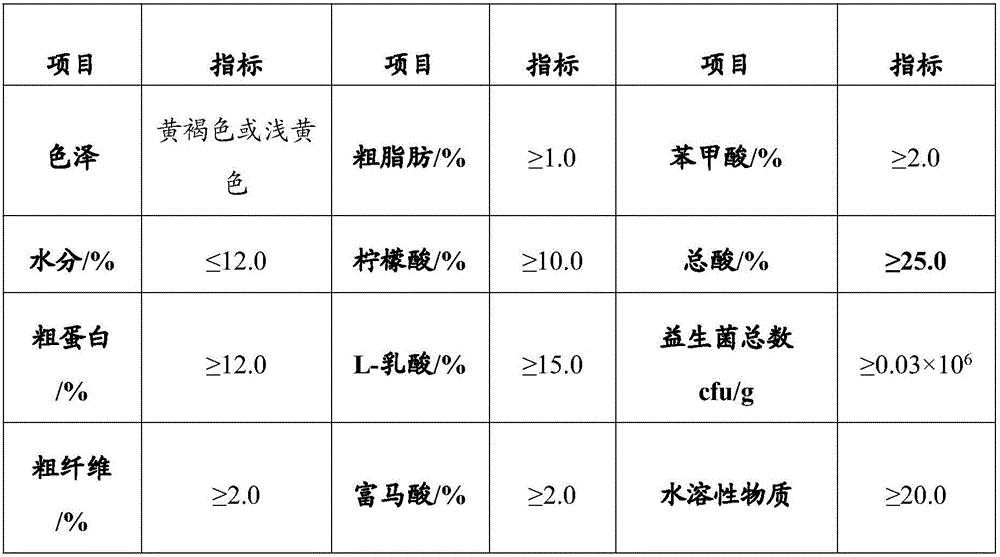

Embodiment 1

[0072] The preparation of a milk lemon compound solid-liquid two-way acidification fermented feed comprises the following steps:

[0073] Crush 100kg of broken rice, add 400kg of water to adjust the slurry, add liquefying enzyme and glucoamylase for enzymatic hydrolysis, and obtain 500kg of saccharified liquid with slag. Through solid-liquid separation, 18kg of sugar residue wet base and 482kg of residue-free saccharification liquid were obtained.

[0074] In 482kg of slag-free saccharification liquid, heat up, sterilize and cool down, insert 20kg of lactic acid bacteria seed solution that produces lactic acid, and carry out under the basic constant conditions of continuous flow of calcium hydroxide solution, temperature 42-45°C, and fermentation pH: 7. Anaerobic fermentation was carried out for 48-60 hours to obtain 482 kg of crude lactic acid fermentation liquid. Add 60kg of 20% dilute sulfuric acid solution to 482kg of lactic acid fermentation broth, acidify to generate ca...

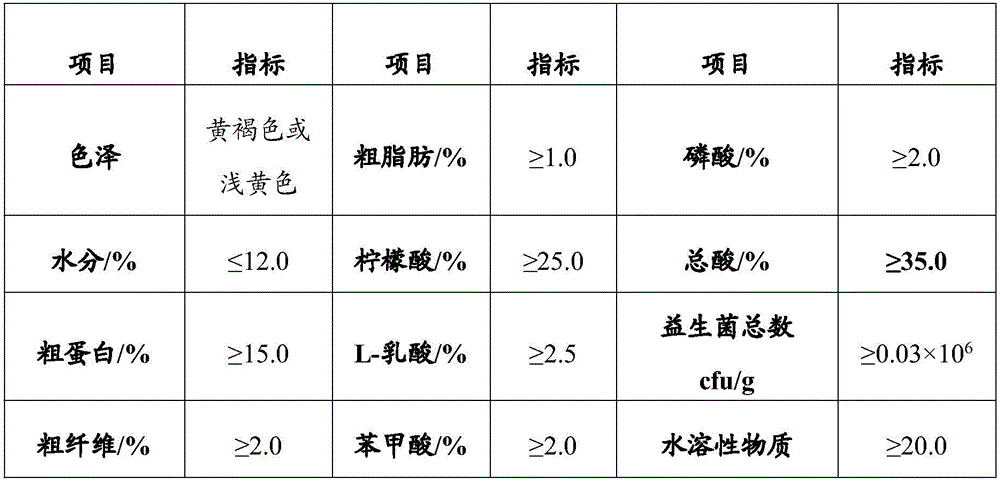

Embodiment 2

[0080] The preparation of a milk lemon compound solid-liquid two-way acidification fermented feed comprises the following steps:

[0081] Grind 100kg of corn, add 300kg of water to adjust the slurry, add liquefaction enzyme and glucoamylase for enzymatic hydrolysis, and obtain 400kg of saccharification liquid with slag. Through solid-liquid separation, 70-75kg of sugar residue wet base and 325-330kg of residue-free saccharification liquid are obtained.

[0082] In 325-330kg slag-free saccharification liquid, heat up, sterilize and cool down, insert 15kg of lactic acid-producing lactic acid bacteria seed solution, add calcium hydroxide solution in continuous flow, temperature 42-45°C, fermentation pH: 7 under basically constant conditions , carry out anaerobic fermentation for 48-60 hours, and obtain 340-345kg of crude lactic acid fermentation liquid. Add 40kg of 20% dilute sulfuric acid solution to 340-345kg of lactic acid fermentation broth to acidify to generate calcium sul...

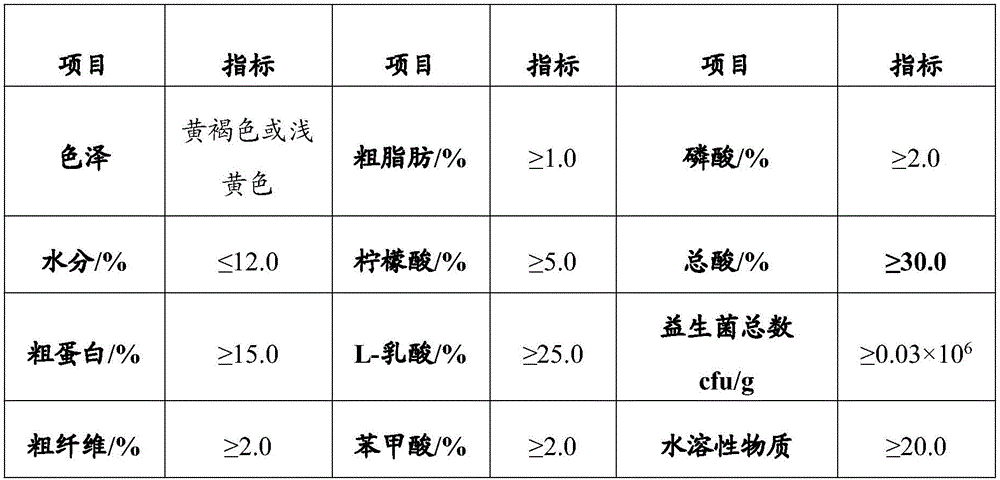

Embodiment 3

[0088] The preparation of a milk lemon compound solid-liquid two-way acidification fermented feed comprises the following steps:

[0089] De-iron the molasses. Weigh 100kg of molasses that has been freed from iron and iron, and add 250kg of water to adjust the slurry to obtain 350kg of slag-free syrup.

[0090] In 350kg of slag-free sugar solution, heat up, sterilize and cool down, insert 20kg of lactic acid bacteria seed solution that produces lactic acid, and carry out under the basic constant conditions of continuous flow of calcium hydroxide solution, temperature 42-45°C, and fermentation pH: 7. Anaerobic fermentation was performed for 48-60 hours to obtain 368-369 kg of crude lactic acid fermentation liquid. Add 30kg of 20% dilute sulfuric acid solution to 368-369kg of lactic acid fermentation broth, acidify to generate calcium sulfate and lactic acid. Through solid-liquid separation, 25kg of lactic acid residue wet base and calcium sulfate wet base, and 373-374kg of la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com