Cap fungus cultivation material and preparation method thereof

A technology of cultivation materials and oyster mushrooms, which is applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of unsatisfactory yield and quality, reduce the economic income of mushroom farmers, and dampen enthusiasm, etc., so as to improve the quality of oyster mushrooms and broaden the cultivation raw materials The effect of channel and growth speed acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

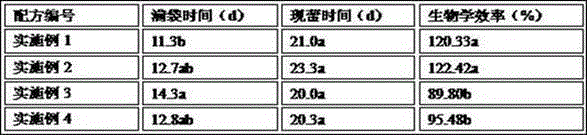

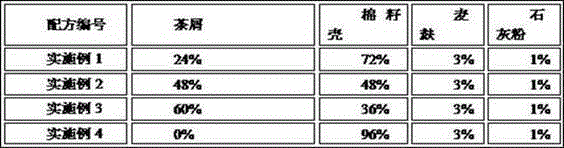

Embodiment 1

[0019] A cultivation material for oyster mushrooms, which comprises 24% of tea dust, 72% of cottonseed hulls, 3% of wheat bran and 1% of lime powder according to the weight percentage.

[0020] The preparation method of described oyster mushroom cultivation material, concrete steps are as follows:

[0021] (1) Weigh each raw material according to parts by weight;

[0022] (2) Put the weighed tea crumbs into water and soak for 23 hours;

[0023] (3) Stir the wheat bran and lime powder into the cottonseed husk;

[0024] (4) Drain the excess water in the tea shavings, sprinkle the mixture of wheat bran, lime powder and cottonseed husks into the drained tea shavings, add water and mix well to keep the water content of the compost at 63% ;

[0025] (5) Put the prepared culture materials into polyethylene plastic bags or polypropylene plastic bags, and carry out normal pressure sterilization or high pressure sterilization before carrying out clinker cultivation management.

Embodiment 2

[0027] A cultivation material for oyster mushrooms, which comprises 48% of tea dust, 48% of cottonseed hulls, 3% of wheat bran and 1% of lime powder according to the weight percentage.

[0028] The preparation method of described oyster mushroom cultivation material, concrete steps are as follows:

[0029] (1) Weigh each raw material according to parts by weight;

[0030] (2) Put the weighed tea crumbs into water and soak for 24 hours;

[0031] (3) Stir the wheat bran and lime powder into the cottonseed husk;

[0032] (4) Drain the excess water in the tea shavings, sprinkle the mixture of wheat bran, lime powder and cottonseed husks into the drained tea shavings, add water and mix well to keep the water content of the compost at 64% ;

[0033] (5) Put the prepared culture materials into polyethylene plastic bags or polypropylene plastic bags, and carry out normal pressure sterilization or high pressure sterilization before carrying out clinker cultivation management.

Embodiment 3

[0035] A cultivation material for oyster mushrooms, comprising: 60% of tea shavings, 36% of cottonseed hulls, 3% of wheat bran, and 1% of lime powder according to the weight percentage.

[0036] The preparation method of described oyster mushroom cultivation material, concrete steps are as follows:

[0037] (1) Weigh each raw material according to parts by weight;

[0038] (2) Put the weighed tea crumbs into water and soak for 25 hours;

[0039] (3) Stir the wheat bran and lime powder into the cottonseed husk;

[0040] (4) Drain the excess water in the tea shavings, sprinkle the mixture of wheat bran, lime powder and cottonseed husks into the drained tea shavings, add water and mix well to keep the water content of the compost at 65% ;

[0041] (5) Put the prepared culture materials into polyethylene plastic bags or polypropylene plastic bags, and carry out normal pressure sterilization or high pressure sterilization before carrying out clinker cultivation management.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com