Heat insulation material with good flame resistance and high mechanical strength, and preparation method thereof

A technology of mechanical strength and thermal insulation materials, applied in the field of thermal insulation materials, can solve problems such as increased thermal conductivity, reduced thermal insulation performance, and reduced mechanical strength, and achieves the effects of increasing smoke suppression, increasing thermal insulation performance, and increasing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

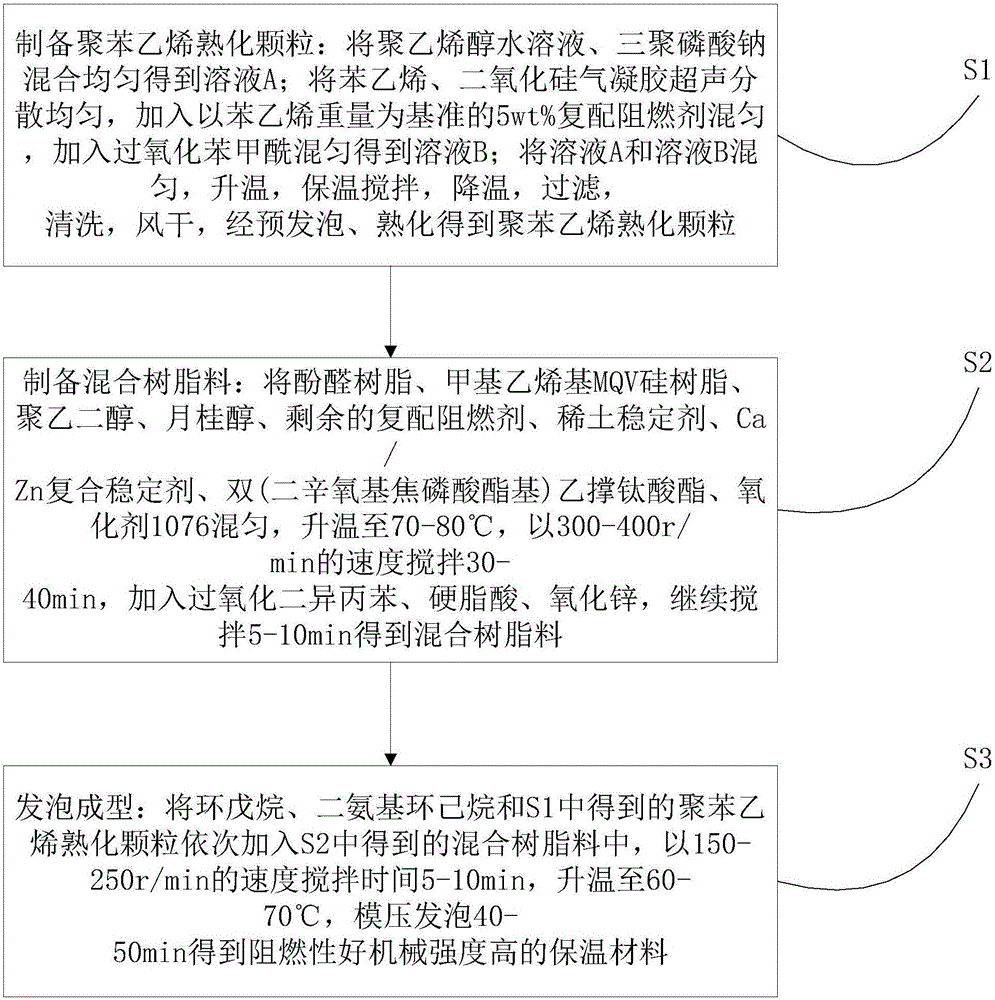

[0023] refer to figure 1 , a kind of preparation method that the present invention proposes the thermal insulation material with good flame retardancy and high mechanical strength, comprises the following steps:

[0024] S1. Preparation of polystyrene mature particles: mix polyvinyl alcohol aqueous solution and sodium tripolyphosphate uniformly to obtain solution A; disperse styrene and silica airgel evenly by ultrasonic, add 5wt% complex compound based on styrene weight Mix with flame retardant, add benzoyl peroxide and mix to obtain solution B; mix solution A and solution B, heat up, keep stirring, cool down, filter, wash, air-dry, pre-foam and mature to obtain polyphenylene Ethylene cured granules;

[0025] S2, preparation of mixed resin material: phenolic resin, methyl vinyl MQV silicone resin, polyethylene glycol, lauryl alcohol, remaining compound flame retardant, rare earth stabilizer, Ca / Zn compound stabilizer, bis(dioctyl alcohol) Oxypyrophosphate) ethylene titanate...

Embodiment 1

[0029] A thermal insulation material with good flame retardancy and high mechanical strength, its raw materials include: 80 parts by weight of styrene, 5 parts of silica airgel, 300 parts of 2wt% polyvinyl alcohol aqueous solution, sodium tripolyphosphate 4 parts, benzoyl peroxide 3 parts, phenolic resin 55 parts, methyl vinyl MQV silicone resin 35 parts, polyethylene glycol 7 parts, lauryl alcohol 6 parts, diaminocyclohexane 17 parts, cyclopentane 20 parts , 30 parts of compound flame retardant, 2 parts of rare earth stabilizer, 2 parts of Ca / Zn composite stabilizer, 2 parts of dicumyl peroxide, 2 parts of stearic acid, 2 parts of zinc oxide, bis(dioctyl oxide 3 parts of base pyrophosphate groups) ethylene titanate, 3 parts of antioxidant 1076;

[0030]Among them, the preparation method of the compound flame retardant is as follows: add expandable graphite to an aqueous ethanol solution with a mass fraction of 85 wt%, disperse evenly by ultrasonic, add 3-aminopropyltriethoxys...

Embodiment 2

[0036] A thermal insulation material with good flame retardancy and high mechanical strength, its raw materials include: 120 parts of styrene, 3 parts of silica airgel, 100 parts of polyvinyl alcohol aqueous solution with a mass fraction of 5 wt%, sodium tripolyphosphate 6 parts, benzoyl peroxide 1 part, phenolic resin 65 parts, methyl vinyl MQV silicone resin 20 parts, polyethylene glycol 9 parts, lauryl alcohol 2 parts, diaminocyclohexane 27 parts, cyclopentane 12 parts 40 parts of compound flame retardant, 1 part of rare earth stabilizer, 4 parts of Ca / Zn composite stabilizer, 1 part of dicumyl peroxide, 4 parts of stearic acid, 1 part of zinc oxide, bis(dioctyl oxide base pyrophosphate) 5 parts of ethylene titanate, 1 part of antioxidant 1076;

[0037] Among them, the preparation method of the compound flame retardant is: adding expandable graphite to an aqueous ethanol solution with a mass fraction of 95% by weight, ultrasonically dispersing it evenly, adding 3-aminopropy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com