Plasma Cleaning Process of Aluminum Foil for Lithium-ion Batteries

A technology of plasma cleaning and lithium ion battery, applied in the field of metal aluminum, can solve the problems of needing solvent, slow decontamination, not environmental protection, etc., and achieves the effect of increasing strength and mechanical properties, improving cleaning speed, and improving cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

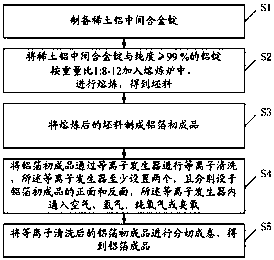

Method used

Image

Examples

preparation example Construction

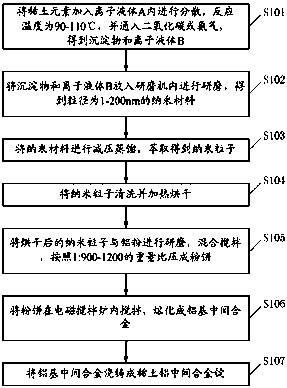

[0068] Further preferably, the preparation method also includes:

[0069] The gas generated in step 1) is pumped into an absorption tank to obtain fertilizer, wherein the absorption tank is soda lime.

[0070] S102. Put the precipitate and the ionic liquid B into a grinder for grinding to obtain nanomaterials with a particle size of 1-200 nm.

[0071] Preferably, the grinder is a diamond grinder.

[0072] The production of high-purity rare earth materials is achieved by chemical sol and gel methods. However, in the process of realizing the chemical sol-gel method, the agglomeration of rare earth ions is very serious. If the particles of rare earth produced by the precipitation method are too large, it will affect the diffusion of rare earth in aluminum, thereby affecting the chemical reaction of aluminum atoms to form regular octahedra. .

[0073] The inventor has proved through a large number of experiments that the particle size of rare earth elements best dispersed in al...

Embodiment 1

[0106] 1. Preparation of rare earth aluminum master alloy ingots:

[0107] 1. Add praseodymium carbonate to 1-ethyl-3-methylimidazolium tricyanomate for dispersion, the weight ratio of praseodymium and 1-ethyl-3-methylimidazolium tricyanomate is 1:1 , the reaction temperature is 90°C, and carbon dioxide is introduced to obtain precipitate and ionic liquid B, and the generated gas is introduced into the soda lime absorption tank, and is absorbed by soda lime to make fertilizer;

[0108] 2. Put the precipitate and ionic liquid B into a diamond grinder for grinding, and grind for 1 hour to obtain nanomaterials with a particle size of 1-200nm;

[0109] 3. Distill the nanomaterials under reduced pressure to obtain nanoparticles;

[0110] 4. Wash the nanoparticles with deionized water, and heat and dry them at a temperature of 100°C;

[0111] 5. Grind the dried nanoparticles and aluminum powder, mix and stir, and press into a powder cake according to a weight ratio of 1:900. The a...

Embodiment 2

[0119] 1. Preparation of rare earth aluminum master alloy ingots:

[0120] 1. Add the ammonium salt of neodymium into 1-butyl-3-methylimidazolium hexafluorophosphate for dispersion, the weight ratio of neodymium and 1-butyl-3-methylimidazolium hexafluorophosphate is 1:1, The reaction temperature is 95°C, and ammonia gas is introduced to obtain precipitates and ionic liquid B. The generated gas is introduced into the soda lime absorption tank and absorbed by soda lime to make fertilizer;

[0121] 2. Put the precipitate and ionic liquid B into a diamond grinder for grinding, and grind for 2 hours to obtain nanomaterials with a particle size of 1-200nm;

[0122] 3. Distilling the nanomaterials under reduced pressure and extracting them to obtain nanoparticles.

[0123] 4. Wash the nanoparticles with deionized water, and heat and dry them at a temperature of 110°C

[0124] 5. Grind the dried nanoparticles and aluminum powder, mix and stir, and press into a powder cake according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com