Sampling film and method for detection and analysis of iron ore sintering flue gas ultrafine particles by using sampling film

A technology of ultra-fine particles and sintering flue gas, applied in the field of iron and steel metallurgy, can solve the problems of poor conductivity, low moisture content of flue gas, high content of impurity ions, etc., achieve corrosion-resistant substrate quality, large particle load capacity, and improve capture efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

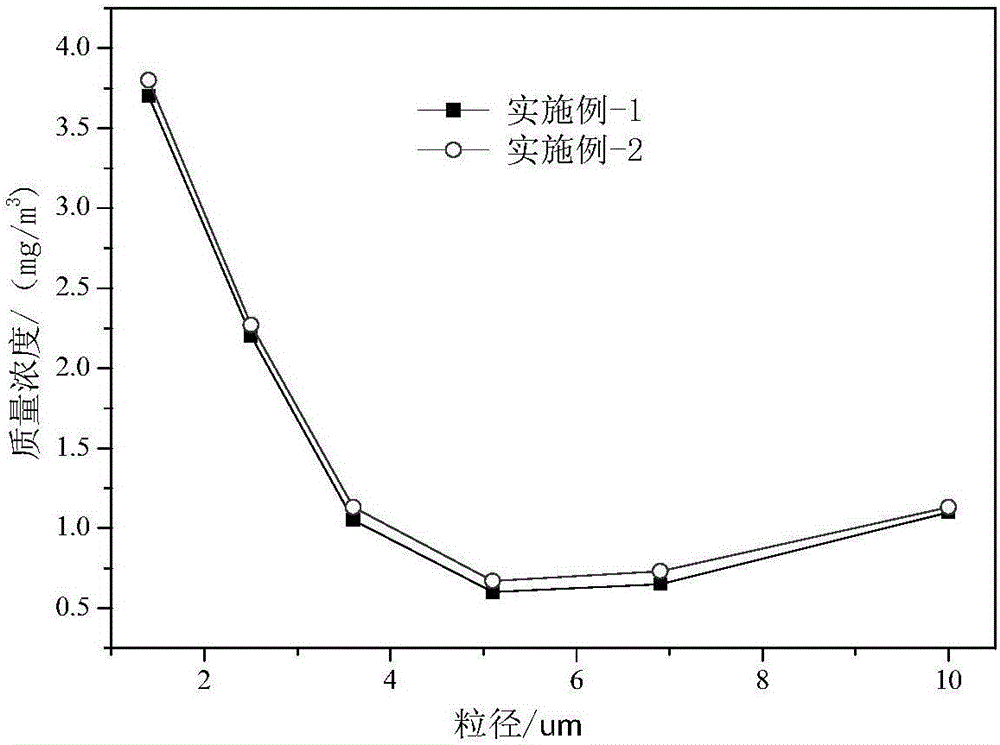

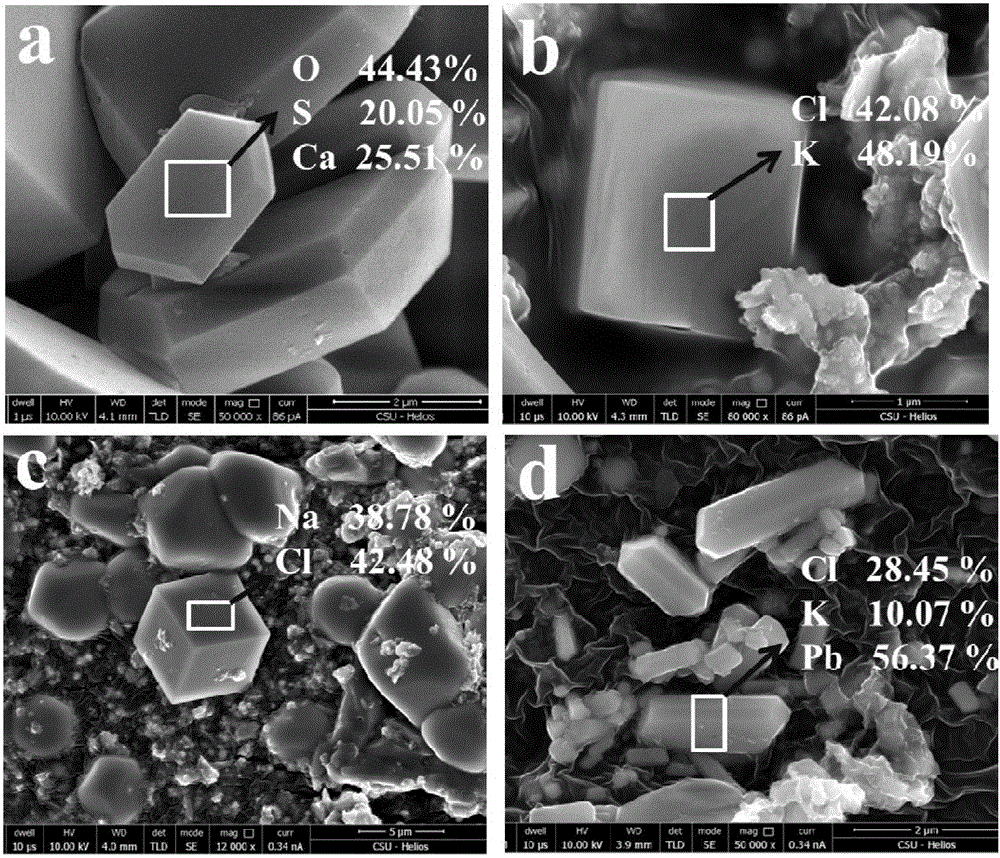

[0039] According to the shape and size of the dust plate of the domestic WY impact dust classifier, a polytetrafluoroethylene film with a thickness of 0.2mm is used to make a matching base film, and a polyimide tape with a thickness of 0.13mm or Graphite carbon conductive tape is evenly pasted on the surface of the base film to prepare a sampling film; the prepared sampling film is heated to a constant weight in a 150oC vacuum drying oven, then taken out and placed in a drying dish to cool to room temperature, and the accuracy of the sample is 0.01mg The analytical balance weighs the weight in the sampling film; the sampling film is installed on the dust plate, and under the sintered raw material conditions shown in Table 1, the required ultrafine particle samples are collected according to the operation method stipulated in the national sampling standard for particulate matter; sampling The final sampled film was placed in a vacuum drying oven at 100°C for 0.5 h, then taken ou...

Embodiment 2

[0041] According to the shape and size of the dust plate of the domestic WY impact dust classifier, a PTFE film with a thickness of 0.4mm is used to make a matching base film, and a polyimide tape with a thickness of 0.2mm or The silver conductive tape is evenly pasted on the surface of the base film to prepare a sampling film; the prepared sampling film is heated to a constant weight in a vacuum oven at 150°C, and then taken out and placed in a drying dish to cool to room temperature. The accuracy of the sample is 0.01mg The analytical balance weighs the weight in the sampling film; the sampling film is installed on the dust plate, and under the sintered raw material conditions shown in Table 1, the required ultrafine particle samples are collected according to the operation method stipulated in the national sampling standard for particulate matter; sampling The final sampled film was placed in a vacuum drying oven at 100°C for 0.5 h, then taken out and placed in a desiccator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com