Method for preparing lactobacillus fermentation liquor from black tea enzymatic hydrolysate

A technology of enzymatic hydrolysis liquid and fermented liquid, which is applied in the direction of acid-containing food ingredients, the function of food ingredients, food ingredients as emulsifiers, etc., can solve the problems of daily life without finding fermented liquid, and achieve the effect of sufficient fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

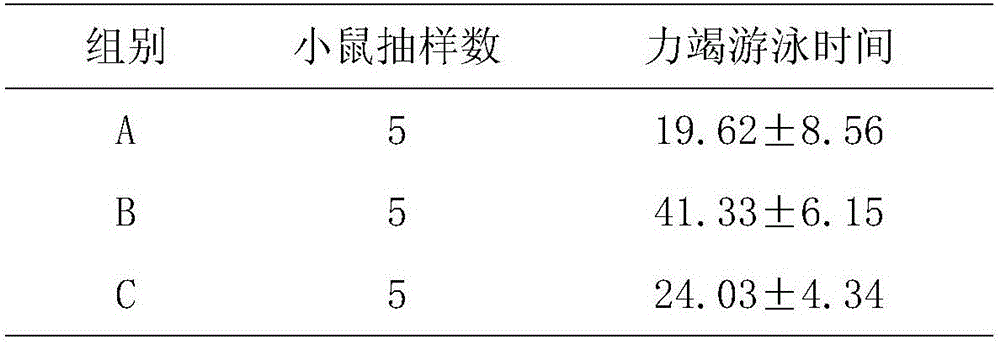

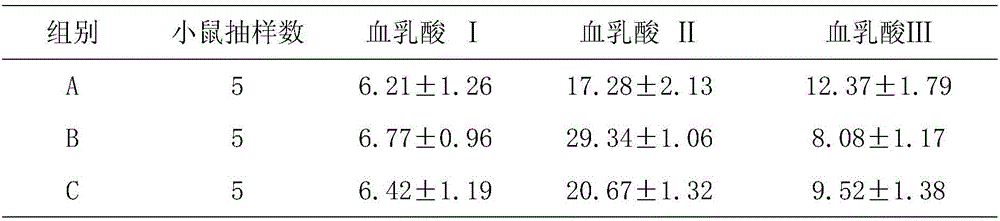

Examples

Embodiment 1

[0022] A method for preparing black tea enzymolysis liquid fermentation liquid, comprising the steps of:

[0023] ⑴ Prepare food enzymatic hydrolysis solution: Soak purple rice, millet, barley, poria cocos, red dates, black plum, tangerine peel, and burnt hawthorn of equal weight, mix according to the weight ratio of food:water 1:9, add the total weight of food and water 1.5% red bean flour and 1.5% 0.05% NaHCO of the total weight of the material 3 , to make it easy to cook, remove fishy smell, and remove bitterness and astringency. After pre-cooking at 80°C for 15 minutes, add citric acid to adjust the pH value to 5.5, add 0.02% of the total weight of food and water with pectinase, keep it at 55°C for 2 hours, add 1% hemicellulase to the total weight of food and water, 0.56% cellulase to the total weight of food and water, 0.5% papain to the total weight of food and water, 0.04% to the total weight of food and water % Phytase for 1 hour, mixed with malt and Divine Comedy for...

Embodiment 2

[0032] A method for preparing black tea enzymolysis liquid fermentation liquid, comprising the steps of:

[0033] ⑴ Prepare food enzymatic hydrolysis solution: Soak purple rice, millet, barley, poria cocos, red dates, black plum, tangerine peel, and burnt hawthorn of equal weight, mix according to the weight ratio of food:water 1:9, add the total weight of food and water 1.5% red bean flour and 1.5% 0.05% NaHCO of the total weight of the material 3 , to make it easy to cook, remove fishy smell, and remove bitterness and astringency. After pre-cooking at 80°C for 15 minutes, add citric acid to adjust the pH value to 5.5, add 0.02% of the total weight of food and water with pectinase, keep it at 55°C for 2 hours, add 1% hemicellulase to the total weight of food and water, 0.56% cellulase to the total weight of food and water, 0.5% papain to the total weight of food and water, 0.04% to the total weight of food and water % Phytase for 1 hour, mixed with malt and Divine Comedy for...

Embodiment 3

[0042] A method for preparing black tea enzymolysis liquid fermentation liquid, comprising the steps of:

[0043] ⑴ Prepare food enzymatic hydrolysis solution: Soak purple rice, millet, barley, poria cocos, red dates, black plum, tangerine peel, and burnt hawthorn of equal weight, mix according to the weight ratio of food:water 1:9, add the total weight of food and water 1.5% red bean flour and 1.5% 0.05% NaHCO of the total weight of the material 3 , to make it easy to cook, remove fishy smell, and remove bitterness and astringency. After pre-cooking at 80°C for 15 minutes, add citric acid to adjust the pH value to 5.5, add 0.02% of the total weight of food and water with pectinase, keep it at 55°C for 2 hours, add 1% hemicellulase to the total weight of food and water, 0.56% cellulase to the total weight of food and water, 0.5% papain to the total weight of food and water, 0.04% to the total weight of food and water % Phytase for 1 hour, mixed with malt and Divine Comedy for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com