A method of laser cladding and chemical dealloying combined to prepare micro-nano structured bulk silicon materials

A technology of chemical dealloying and micro-nano structure, which is applied in the field of laser cladding technology combined with chemical dealloying technology to prepare micro-nano structure bulk silicon materials, can solve the problems of difficult control of micro-nano silicon material structure and high reaction conditions, and achieve organizational The effect of small size, simple preparation method and simple condition requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Raw materials:

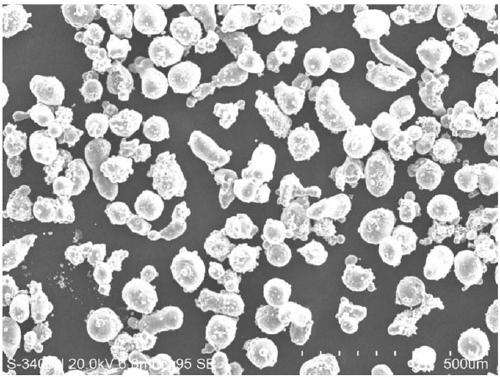

[0026] (1) Aluminum-silicon powder (-325 mesh, 99%), Al:Si=95:5wt.%, particle size about 80 μm.

[0027] (2) Aluminum plate, purity: 99.0%, size: 100mm×50mm×5mm.

[0028] (3) Etching solution: 3mol / L HCL solution.

[0029] 2. Preparation method

[0030] Step 1. Preparation of precursor alloy material:

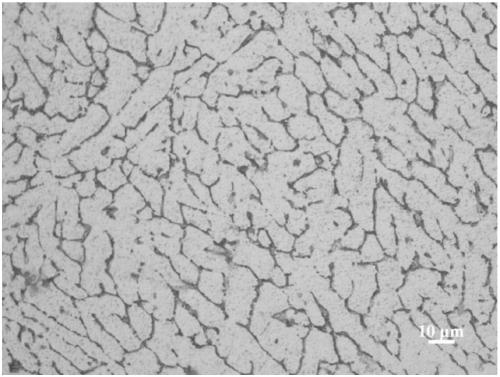

[0031] Put the aluminum-silicon powder on the base material aluminum plate (100mm×50mm×5mm), the preset thickness is about 1mm, use YLS-6000 fiber laser for cladding, laser power: 5kW, spot diameter: 5mm, scanning speed: 4mm / s, argon shielding gas flow rate: 15L / min. Then wire cutting is used to separate the cladding layer from the substrate to obtain a precursor alloy material.

[0032] Step 2, chemical dealloying treatment:

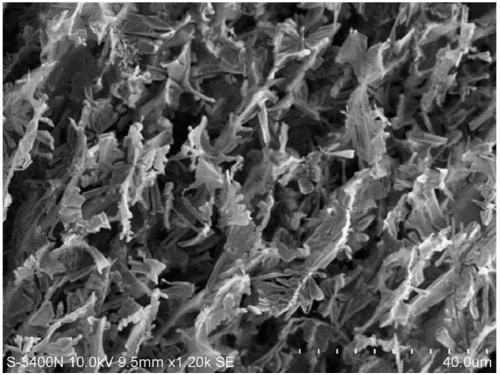

[0033] The precursor alloy material prepared by cladding was immersed in 3mol / L HCL solution and corroded for 2 hours until the reaction stopped, and then the micro-nano structure intermediate obtained after corrosion wa...

Embodiment 2

[0035] 1. Raw materials:

[0036] (1) Aluminum-silicon powder (-325 mesh, 99%), Al:Si=88:12wt.%, particle size about 80 μm.

[0037] (2) Aluminum plate, purity: 99.0%, size: 100mm×50mm×5mm.

[0038] (3) Etching solution: 3mol / L HCL solution.

[0039] 2. Preparation method

[0040] Step 1: Preparation of precursor alloy material:

[0041] Put the aluminum-silicon powder on the base material aluminum plate (100mm×50mm×5mm), the preset thickness is about 2mm, use YLS-6000 fiber laser for cladding, laser power: 5.5kW, spot diameter: 5mm, scanning speed: 8mm / s, argon protective gas flow: 15L / min. Then wire cutting is used to separate the cladding layer from the substrate to obtain a precursor alloy material.

[0042] Step 2, chemical dealloying treatment:

[0043] The precursor alloy material prepared by cladding was immersed in 3mol / L HCL solution and corroded for 8 hours until the reaction stopped, and then the micro-nano structure intermediate obtained after corrosion was ...

Embodiment 3

[0045] 1. Raw materials:

[0046] (1) Aluminum-silicon powder (-325 mesh, 99%), Al:Si=50:50wt.%, particle size about 80 μm.

[0047] (2) Aluminum plate, purity: 99.0%, size: 100mm×50mm×5mm.

[0048] (3) Etching solution: 3mol / L HCL solution.

[0049] 2. Preparation method

[0050] Step 1: Preparation of precursor alloy material:

[0051] Put the aluminum-silicon powder on the base material aluminum plate (100mm×50mm×5mm), the preset thickness is about 2mm, use YLS-6000 fiber laser for cladding, laser power: 5.5kW, spot diameter: 5mm, scanning speed: 10mm / s, argon shielding gas flow: 15L / min. Then wire cutting is used to separate the cladding layer from the substrate to obtain a precursor alloy material.

[0052] Step 2, chemical dealloying treatment:

[0053] The precursor alloy material prepared by cladding was immersed in 3mol / L HCL solution and corroded for 12 hours until the reaction stopped, and then the micro-nano structure intermediate obtained after corrosion was w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com