Method for recycling tetrahydrofuran in tetrahydrofuran-methanol-water by single-tower extractive distillation

A technology of tetrahydrofuran and extractive distillation, which is applied in the direction of extractive distillation, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of complex process, high energy consumption, complex process, etc., and achieve simple and easy process and realize recovery Effects of reusing and reducing separation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

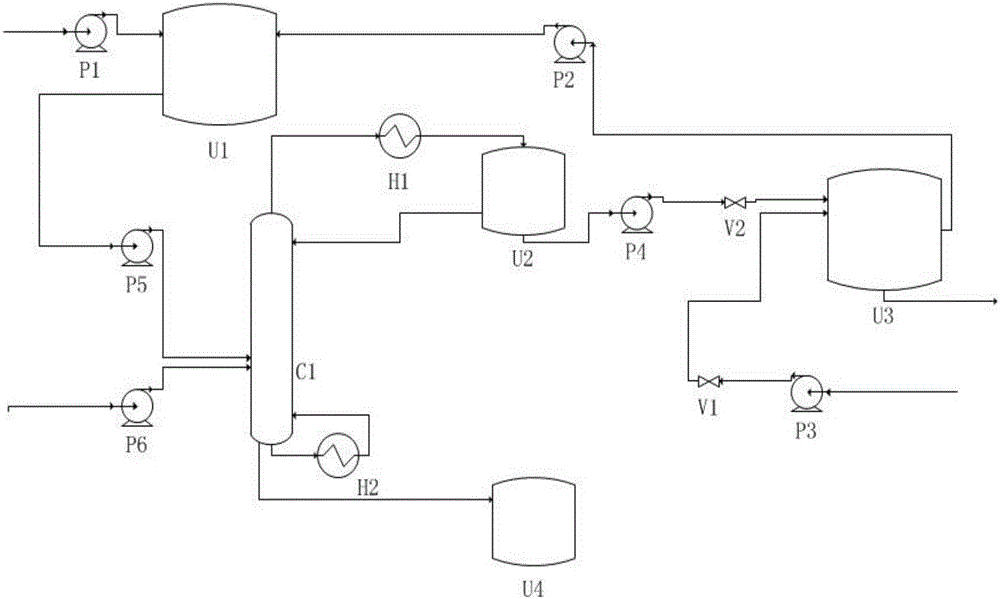

Image

Examples

Embodiment 1

[0035]The feed flow rate of tetrahydrofuran-methanol-water mixed liquid is 1400kg / h, normal temperature, pressure 1atm, mass composition: tetrahydrofuran 75%, methanol 6%, water 19%. The feed flow ratio of extractant to tetrahydrofuran-methanol-water mixture is 3.5:1. The operating pressure of extractive distillation column C1 is 1 atm, the reflux ratio is 1, the number of trays is 18, the mixed liquid feeding plate is the 12th plate, the extractant feeding plate is the 12th plate, and the tower top temperature is 32.9°C , the temperature at the bottom of the tower is 64.5°C. The extractant is 2-methyl-2-butene, and after being separated by extractive distillation column C1, the purity of tetrahydrofuran extracted from the bottom of the column is 99.5%, and the yield is 99.7%. In the phase separator U3, after phase separation, the purity of the organic phase extraction agent 2-methyl-2-butene extracted from the upper layer is 99.6%, and it is transported to the mixing tank U1...

Embodiment 2

[0037] The feed flow rate of tetrahydrofuran-methanol-water mixed liquid is 1320kg / h, normal temperature, pressure 2atm, mass composition: tetrahydrofuran 80%, methanol 12%, water 8%. The feed flow ratio of extractant to tetrahydrofuran-methanol-water mixture is 2:1. The operating pressure of extractive distillation column C1 is 2atm, the reflux ratio is 0.8, the number of trays is 35 plates, the mixed liquid feeding plate is the 18th plate, the extractant feeding plate is the 18th plate, and the tower top temperature is 53.8°C , the temperature at the bottom of the tower is 89°C. The extractant is 2-methyl-2-butene, and after being separated by extractive distillation column C1, the purity of tetrahydrofuran extracted from the bottom of the column is 99.8%, and the yield is 99.5%. In the phase separator U3, after phase separation, the purity of the organic phase extraction agent 2-methyl-2-butene extracted from the upper layer is 99.7%, and it is transported to the mixing ta...

Embodiment 3

[0039] The feed flow rate of tetrahydrofuran-methanol-water mixed liquid is 1480kg / h, normal temperature, pressure 1.5atm, mass composition: tetrahydrofuran 78%, methanol 9%, water 13%. The feed flow ratio of extractant to tetrahydrofuran-methanol-water mixture is 4:1. The operating pressure of extractive distillation column C1 is 1.5atm, the reflux ratio is 1.5, the number of trays is 25 plates, the mixed liquid feed plate is the 16th plate, the extractant feed plate is the 16th plate, and the tower top temperature is 46.1 °C, the temperature at the bottom of the tower was 79 °C. The extractant is 2-methyl-2-butene, and after being separated by extractive distillation column C1, the purity of tetrahydrofuran extracted from the bottom of the column is 99.7%, and the yield is 99.6%. In the phase separator U3, after phase separation, the purity of the organic phase extraction agent 2-methyl-2-butene extracted from the upper layer is 99.8%, and it is transported to the mixing ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com