Method for greening original soil of slight alkaline land through water-retaining agent containing cellulose degradation bacteria

A technology of cellulose-degrading bacteria and water-retaining agent, applied in the field of landscaping, can solve the problems of poor water-retaining capacity of NaCl solution, poor water-absorbing capacity of NaCl solution, poor water-retaining capacity, etc., achieve good water-retaining effect, good water-retaining capacity, and increase water content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

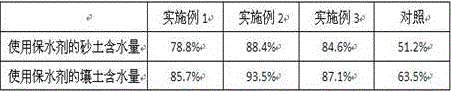

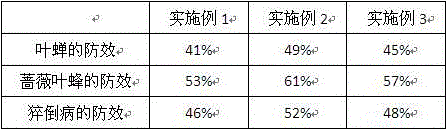

Examples

Embodiment 1

[0039] Example 1 A water-retaining agent containing cellulose-degrading bacteria

[0040] Described water retaining agent, the mass ratio of each raw material component is:

[0041] 30 parts of leaf powder, 0.05 parts of white decay bacteria, 0.5 parts of cellulose degrading bacteria, 1 part of buckwheat straw powder, 1.5 parts of rice husk powder, 1 part of enteromorpha powder, 1 part of iron nail vegetable powder, 1 part of japonica rice starch, 0.5 parts of arrowroot starch, 1 part of potassium carbonate, 0.5 parts of phosphorus nitrate, 1 part of fermented sheep manure, 0.5 parts of fermented deer manure, 1 part of shell powder, 1 part of corn germ meal powder, 1 part of indole butyric acid, fulvic acid 1 part, 250 parts of water.

[0042] The mesh number of described leaf powder is 120~350 meshes, comprises pine leaf powder, poplar leaf powder, elm leaf powder, tree leaf powder, silk tree leaf powder, and the mass ratio of described each composition is 9:2:4:5: 7;,

[...

Embodiment 2

[0056] Embodiment 2 A kind of water retaining agent containing cellulose degrading bacteria

[0057] Described water retaining agent, the mass ratio of each raw material component is:

[0058] 50 parts of leaf powder, 0.1 part of white decay bacteria, 1 part of cellulose degrading bacteria, 2 parts of buckwheat straw powder, 3 parts of rice husk powder, 2 parts of enteromorpha powder, 2 parts of iron nail vegetable powder, 2 parts of japonica rice starch, arrowroot 1 part of starch, 2 parts of potassium carbonate, 1 part of phosphorus nitrate, 2 parts of fermented sheep manure, 1 part of fermented deer manure, 2 parts of shell powder, 2 parts of corn germ meal powder, 2 parts of indole butyric acid, 2 parts of fulvic acid , 450 parts of water.

[0059] The mesh number of described leaf powder is 120~350 meshes, comprises pine leaf powder, poplar leaf powder, elm leaf powder, tree leaf powder, silk tree leaf powder, and the mass ratio of described each composition is 9:2:4:5: ...

Embodiment 3

[0073] Embodiment 3 A kind of water retaining agent containing cellulose degrading bacteria

[0074] Described water retaining agent, the mass ratio of each raw material component is:

[0075] 70 parts of leaf powder, 0.15 parts of white decay bacteria, 1.5 parts of cellulose degrading bacteria, 3 parts of buckwheat straw powder, 4.5 parts of rice husk powder, 3 parts of enteromorpha powder, 3 parts of iron nail vegetable powder, 3 parts of japonica rice starch, arrowroot 1.5 parts of starch, 3 parts of potassium carbonate, 1.5 parts of phosphorus nitrate, 3 parts of fermented sheep manure, 1.5 parts of fermented deer manure, 3 parts of shell powder, 3 parts of corn germ meal powder, 3 parts of indole butyric acid, 3 parts of fulvic acid , 650 parts of water.

[0076] The mesh number of described leaf powder is 120~350 meshes, comprises pine leaf powder, poplar leaf powder, elm leaf powder, tree leaf powder, silk tree leaf powder, and the mass ratio of described each composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com