Hydrogel collagen dressing especially suitable for oily skins

A collagen and oily skin technology, applied in the field of collagen dressings and hydrogel collagen dressings, can solve the problems of unconcerned about the transdermal absorption speed of collagen, and achieve faster transdermal absorption speed, significantly improved, transdermal The effect of improving the absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

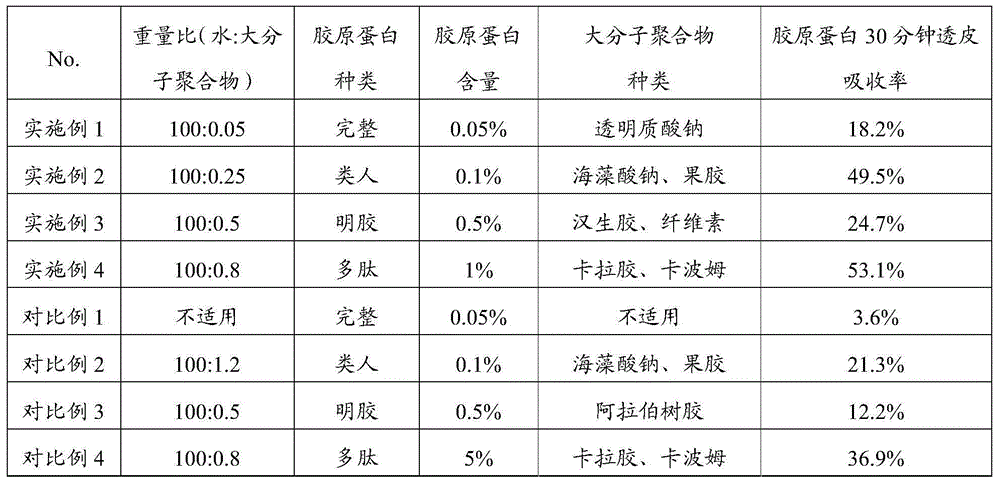

Examples

Embodiment 1

[0045] Example 1. Hydrogel collagen dressing 1 (0.05% complete macromolecular collagen+water+macromolecular polymer)

[0046] Ingredients: sodium hyaluronate 0.05% (macromolecular polymer), glycerin 8.0%, butanediol 5.0%, glyceryl polyether-26 2.0%, tocopheryl acetate 0.5%, intact macromolecular collagen 0.05%, benzene Oxyethanol 0.2%, ethylhexylglycerin 0.1%, triethanolamine 0.6%, making the total 100% water.

[0047] Process operation:

[0048] ①Use 0.05mol / L acetic acid to pre-dissolve the complete macromolecular collagen, and after complete dissolution, use 0.01mol / L sodium hydroxide solution to adjust its pH to 5.0-6.0, and make the final concentration of the mother liquor to 0.05%;

[0049] ② Add sodium hyaluronate to water and stir until fully swollen; then add glycerin, butylene glycol, and glycerol polyether-26 in turn, stir until uniform under heating conditions, then add quantitative collagen mother liquor, stir until uniform, Insulate at -85°C for 30 minutes; ...

Embodiment 2

[0051] Example 2. Hydrogel-type collagen dressing 2 (0.1% human-like collagen+water+macromolecular polymer)

[0052] Ingredients: Sodium Alginate 0.05%, Pectin 0.2% (macromolecular polymer), Glycerin 5.0%, Butylene Glycol 3.0%, Betaine 2.0%, Tocopheryl Acetate 0.5%, Human Collagen 0.1%, Benzene Oxyethanol 0.2%, ethylhexylglycerin 0.1%, triethanolamine 0.5%, making the total 100% water.

[0053] Process operation:

[0054] ① Add sodium alginate and pectin to water, stir until fully swollen; then add glycerin, butylene glycol, betaine, and human-like collagen in sequence, stir until uniform under heating, and keep warm at 80-85°C for 30 minutes;

[0055] ② After the heat preservation is over, cool down to 40-45°C, add tocopheryl acetate, phenoxyethanol, and ethylhexylglycerin, stir well, then add triethanolamine, stir until evenly, and then cool down.

Embodiment 3

[0056] Embodiment 3. Hydrogel type collagen dressing 3 (0.5% gelatin+water+macromolecular polymer)

[0057] Ingredients: xanthan gum 0.3%, cellulose 0.2% (macromolecular polymer), glycerin 8.0%, butylene glycol 5.0%, glyceryl polyether-26 2.0%, tocopheryl acetate 0.5%, gelatin 0.5%, benzene Oxyethanol 0.2%, ethylhexylglycerin 0.1%, triethanolamine 0.6%, making the total 100% water.

[0058] Process operation:

[0059] ① Add xanthan gum and cellulose into water, stir until fully swollen; then add glycerin, butylene glycol, glyceryl polyether-26, and gelatin in sequence, stir until uniform under heating conditions, and keep warm at 80-85°C for 30 minutes;

[0060] ② After the heat preservation is over, cool down to 40-45°C, add tocopheryl acetate, phenoxyethanol, and ethylhexylglycerin, stir well, then add triethanolamine, stir until evenly, and then cool down.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com