A method for preparing high-purity rhenium powder from rhenium-containing high-arsenic copper sulfide

A copper sulfide, high-purity technology, applied in the field of preparing high-purity rhenium powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

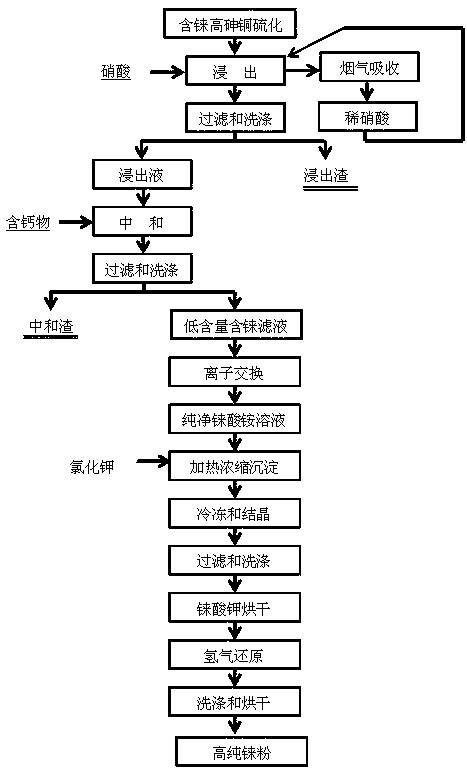

[0029] Refer to the attached figure, conditions: 1000 grams of rhenium-arsenic copper sulfide raw material, the amount of nitric acid added is twice the weight ratio of the rhenium-arsenic copper sulfide raw material, slowly heated to 85°C, stirring speed is 250rpm, leaching time is 5h, flue gas Enter the absorption tower, use oxygen enrichment and water spray to absorb, form dilute nitric acid, after leaching, filter and wash to obtain leaching liquid and leaching residue respectively, add quicklime to the leaching liquid and stir to neutralize residual nitric acid, control pH to 8.5, filter and wash , to obtain arsenic-copper slag and a low-content rhenium-containing filtrate, respectively, wherein the arsenic and copper in the slag enter the slag in the form of calcium arsenate and copper hydroxide respectively; the low-content rhenium-containing filtrate uses D296 resin for ion exchange, after exchange and elution , to obtain pure ammonium rhenate solution, after heating an...

Embodiment 2

[0031] Refer to the attached drawing, conditions: 1500 grams of rhenium-arsenic copper sulfide raw material, the amount of nitric acid added is 3.5 times the weight ratio of rhenium-arsenic copper sulfide raw material, slowly heated to 95°C, stirring speed is 250rpm, leaching time is 4h, flue gas Enter the absorption tower, use sodium persulfate and water spray to absorb, form dilute nitric acid, filter and wash after leaching, obtain leaching liquid and leaching residue respectively, add hydrated lime to the leaching liquid and stir to neutralize residual nitric acid, control pH to 9.0, filter and Wash to obtain arsenic-copper slag and low-content rhenium-containing filtrate respectively, wherein the arsenic and copper in the slag enter the slag in the form of calcium arsenate and copper hydroxide respectively; the low-content rhenium-containing filtrate uses Tulsion CR-75 resin for ion exchange, after Exchange and elution to obtain pure ammonium rhenate solution, after heatin...

Embodiment 3

[0033] Refer to the attached drawing, conditions: 8000 grams of rhenium-arsenic-containing copper sulfide raw material, the amount of nitric acid added is 4.0 times the weight ratio of the rhenium-arsenic-containing copper sulfide raw material, slowly heated to 85°C, the stirring speed is 250rpm, the leaching time is 5h, the flue gas Enter the absorption tower, use hydrogen peroxide and water spray to absorb, form dilute nitric acid, filter and wash after leaching, obtain leaching liquid and leaching residue respectively, add hydrated lime to the leaching liquid and stir to neutralize residual nitric acid, control pH to 9.5, filter and wash, The arsenic-copper slag and the low-content rhenium-containing filtrate were respectively obtained, wherein the arsenic and copper in the slag entered the slag in the form of calcium arsenate and copper hydroxide respectively; the low-content rhenium-containing filtrate was ion-exchanged with Tulsion RCX-5143 resin, and after exchange and E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com